From: Schroeder Industries’ Filter Systems and Diagnostics (IoT) Product Group

Overcoming “Phantom” Particle Counting

Imagine this…

- You have been filtering 30 gallons of your operating fluid in bypass with staged 5- and 1-micron filter elements at a processing rate of five gallons per minute (gpm) (300 gallons per hour (gph)).

- You have been using a Light Blockage Method (LBM)-based portable particle counter to verify the fluid cleanliness.

- The starting cleanliness per ISO 4406 2017 was 25/22/15 ISO cleanliness code.

- After eight (8) hours, the cleanliness has only dropped to 22/20/13 ISO cleanliness code.

- A difference of about 3 points.

- You’ve checked that the filter element is not clogged and not in bypass.

- You even went through the trouble of making sure there was an element actually in the filter!

How could this be possible?

It couldn’t be, right?

What you’re likely experiencing is a classic case of “phantom” particle counting.

Demystifying the “Phantoms” in your Fluid

“Phantom” particle counting is a documented problem faced when using LBM portable counters to verify the oil cleanliness class of petroleum-based fluids containing certain insoluble additives.

Silicone-based antifoam agents are common interferents of LBM particle counters.

Fluids used in mobile fluid power systems are typically formulated to contain high antifoam concentrations.

Research has suggested that through differential surface tension, the silicone antifoam additive agents adhere to the inner wall of microscopic, entrained air bubbles, resulting in micelle-like encapsulations of the additive agents that then take on the apparent shape characteristics of a water droplet [1].

The measurement of particle size for micelle-like antifoam agent encapsulations typically range in 4-10µm size range [2].

Once the encapsulations rise to the fluid surface, the agents quickly pierce the air bubble and return back into the fluid.

In a related study of the effects of a variety of non-solid contaminants and additives on LBM particle counting accuracy, it was found that a base stock mixture containing 0.02% (by weight) of a silicone antifoam agent increased the LBM laser particle count by a minimum factor of three [1].

The erroneous particle accounts were particularly evident in the 4µm and 6µm channels of the ISO 4406 2017 cleanliness standard [2, 3] (see also NAS cleanliness standard or SAE AS4059).

Limitations of the Light Blockage Method (LBM)

LBM or Light Blockage Method fluid analyzers are useful in many applications.

The principle of the light blockage method is fundamentally simple: fluid flows through a measurement cell containing a light source on one side of the measurement cell, and a receiver (photodetector) on the opposing side of the measurement cell.

The light source becomes partially blocked as the number of particles pass through the measurement cell, creating a light radiation differential—a shadow—corresponding to the circular cross-sectional size of the passing particles.

The operating principle measures particles based on the space between the shadow and the receiving end of the light source.

Because of this fundamental operating principle, LBM portable counters suffer from a key drawback: the lack of and the inability to discern solid contaminates (like metallic composition) from other contaminates like water, air bubbles, “phantom” particles, and so on.

So, how can the “phantom” particles be overcome using oil particle counter sensor technology?

There is an alternative solution to this question: oil particle counting using the Direct Imaging Method.

Direct Imaging Method

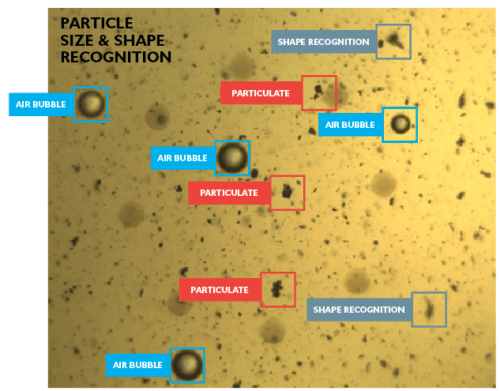

Direct Imaging particle counting software uses size and shape-recognition technology, based on advanced algorithms, as a dirt classifier to distinguish contaminates.

For example, a Direct Imaging portable information counter can distinguish contaminates into fatigue, cutting and sliding wear with a metallic wear debris sensor and fiber and air bubble categories based on shape characteristics.

It can also recognize water droplets.

The distinction of contaminates allows for a more accurate particle counting by negating non-solid contaminates like entrained air bubbles and water droplets.

Therefore, Direct Imaging particle counting technology can negate the micelle-like antifoaming additive encapsulations as water droplets— “phantom” particles—allowing users to understand the condition of their fluid samples with confidence.

Case Studies 1 and 2 demonstrate how the Schroeder Pro: Total Fluid Health (TFH)–one example of a fluid condition monitoring solution with Direct Imaging particle counting technology–can be used in practical applications to overcome “phantom” particle counting.

Case Study 1

An OEM of large off-highway equipment was experiencing continuous oil particle counter inaccuracies at a verification stage of assembly:

- The rejections due to fluid condition were mounting, causing delayed shipments and significant related costs.

- The average holding time delay due to rejection was seven days and incurred a holding cost of $1,500, per day, per unit.

- At the consultation phase of the case study, eight units had been delayed.

The diagnosis was in…

The existing light-blockage-type particle counters were providing inconsistently high and erroneous particle counts.

The ISO 4406 2017 ISO cleanliness code would frequently measure a 23/22/19 size range, despite a strong fluid maintenance and conditioning regime.

Third-party fluid analyzer reports and fluid datasheets suggested that the fluid (synthetic hydraulic fluid) contained a high concentration of a siloxane (silicone derivative) antifoaming additive known to cause “phantom” particle measurements in LBM automatic particle counters.

Schroeder Industries provided an extensive on-site demonstration that proved the advanced Direct Imaging Method technology of the Schroeder Pro: Total Fluid Health (TFH) hydraulic fluid particle counter solution, which measured an average ISO 4406 2017 fluid cleanliness of 15/14/10, allowed the customer to successfully process the fluid of and pass six units during the first day of demonstration.

The two remaining backlogged units passed early on the second day of demonstration.

The realizable savings—evidenced by the demonstration—equated to:

- Approximately 35% in cost savings and

- 81% reduction in holding time.

Case Study 2

Similar to Case Study 1, an OEM of mobile equipment was measuring unusually high particle counts with their LBM computer particle analyzer after switching to a new hydraulic fluid type with a higher concentration of an antifoaming additive.

Coincidentally, the fluid type was nearly equivalent to that used by the off-highway equipment OEM.

According to the customer, the average oil particle counter of four fluid sample trays of fluid collected from the customer’s well-conditioned bulk fluid storage measured 25/23/20 iso cleanliness code, as shown in table 1.

| Sample | ≥4µm | ≥6µm | ≥14µm |

| I | 25 | 23 | 19 |

| II | 25 | 23 | 19 |

| III | 25 | 23 | 21 |

| IV | 25 | 23 | 19 |

| Average | 25 | 23 | 20 |

Table 1 Sample cleanliness results of fluid containing a high concentration of antifoaming additives according to ISO 4406 2017

After consulting the customer of the “phantom” oil particle counting issue, Schroeder Industries offered to process fluid samples using a third-party LBM portable counter and the Schroeder Pro: Total Fluid Health (TFH) hydraulic fluid particle counter solution to determine if there was evidence of the phenomenon.

Because of the tell-tale symptoms of particle counting inaccuracies due to “phantom” particle size analysis, the results of the tests shown in table 2 are not surprising; the test results are consistent with typical cleanliness discrepancies produced by “phantom” particles.

| Sample | Processed w/ Third-Party LBM Particle Counter | Processed w/ TFH |

| I – Bulk Fluid Storage Tank | 24/23/18 | 17/16/15 |

| II – Machine Reservoir | 23/21/16 | 18/17/16 |

Table 2 Comparative sample cleanliness results of fluid containing a high concentration of antifoaming additives according to ISO 4406

Keep on Counting…with Direct Digital Technology

It’s no secret that understanding fluid cleanliness is imperative for strategically maintaining fluid-powered and lubricated machines.

Automatic particle counters using the Light Blockage Method (LBM) are generally considered reliable solutions for fluid storage monitoring.

However, LBM particle counters can yield inaccurate measurements while processing fluids that are contaminated by water, entrained air, or high levels of certain additives.

Silicone-based antifoaming agents are common, well-documented additive interferents that become encapsulated within entrained air bubbles that lead to a phenomenon referred to as “phantom” particles.

“Phantom” particles are indiscernible by LBM particle counters due to their fundamental principle of operation.

Research suggests that “phantom” particles can lead to LBM particle counter measurements to be greater than three classes higher than the true cleanliness per ISO 4406 2017.

While they can be filtered out—one possible reason for the slight cleanliness improvement in the hypothetical scenario of the introduction–the additives that can lead to “phantom” particles serve important, specific functions and should not be removed or sacrificed.

An alternative solution to LBM automatic particle counting is the Direct Imaging Method.

The Direct Imaging Method of particle counting uses size and shape-recognition technology in tandem with advanced data-driven algorithms to distinguish solid contaminates into metallic wear debris sensor and fiber categories, and from non-solid contaminants like water droplets and air bubbles.

Because of the apparent water droplet-like shape characteristics of the antifoam encapsulations, Direct Imaging solutions such as the Schroeder Pro: Total Fluid Health (TFH) can indirectly negate the “phantom” particle counts and provide more accurate fluid cleanliness measurements.

References:

[3] Nadasdi, T. (2007, May). Do we really know what we are measuring? Efficiency Plant.

For more information on demystifying “Phantom” Particle Counts, please contact us.