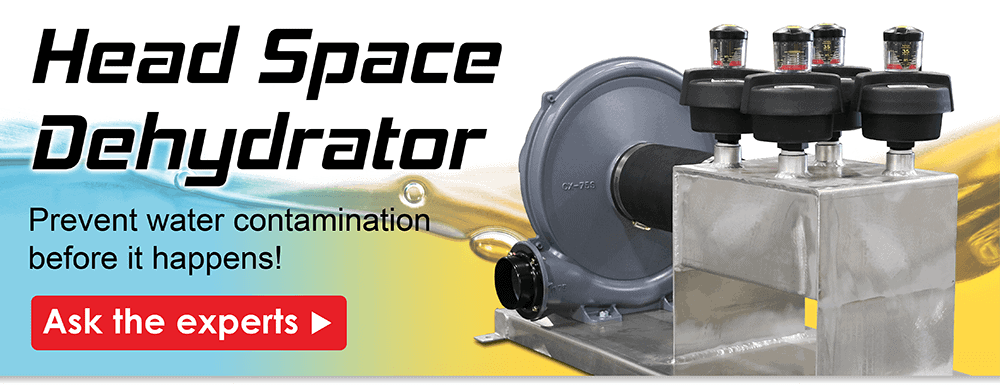

Unlock Peace of Mind: Prevent Water Contamination Fast

Leave a Comment

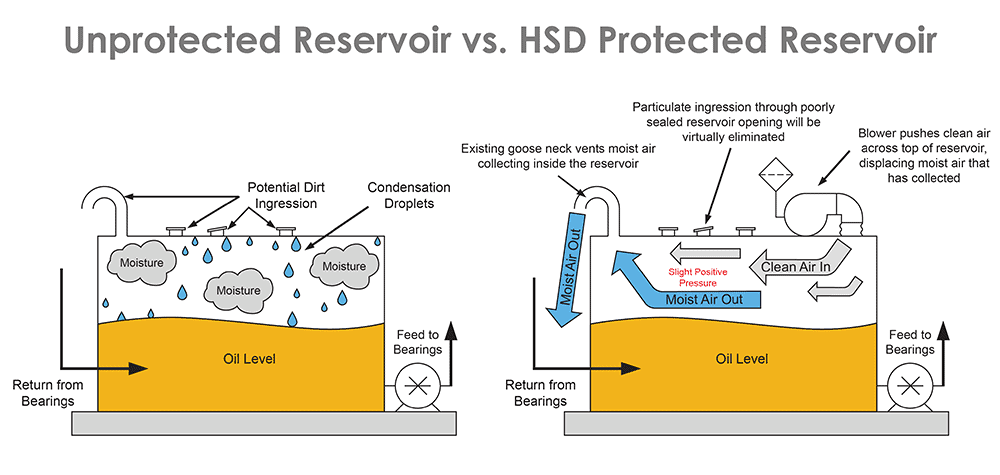

Most hydraulic reservoirs in major industries including pulp & paper, primary metals, and more feature a pocket of open space between the fluid level and the top of the reservoir. This open space, known as head space, fills with moisture as humid air ingresses via faulty seals, vents, and other entry points.

As the moisture builds in the head space, water condenses at the top of the reservoir, eventually coalescing and falling into the oil.

This water contamination can cause a range of serious problems which can impact your equipment’s efficiency and may require repairs, including:

- Rust

- Cavitation

- Sensor failures

- Reduced oil lubricity

How Schroeder’s Head Space Dehydrator Helps:

Dewatering units such as the Triton Dehydration Stations are excellent for targeting water contamination when oil has already become saturated, but preventing contamination before it reaches critical levels is ideal.

The new Head Space Dehydrator is designed to combat moisture in the head space of a hydraulic reservoir before it contaminates the oil. This unit is permanently installed on a hydraulic reservoir so that humidity inside the reservoir can be managed continuously.

Here’s how it works:

- The Head Space Dehydrator assembly pulls ambient air into the chamber through a series of particulate breathers.

- The clean, dry air is then blown through the head space above the fluid level, displacing and venting the moist internal air though existing ventilation points.

- As the moist air is displaced, the opportunity for water contamination via condensation is reduced.

Ask the experts at Schroeder what the HSD can do for your application!

Contact-Blog-HSD Introduction

Triton Dehydrators: The Ultimate in Mass Transfer Dewatering Filtration

Leave a Comment

Water Contamination Can Damage Your Hydraulic System

Water contamination in hydraulic systems is a common problem, which can severely reduce the life of hydraulic systems and fluids. If your hydraulic fluid appears milky when sampled, it’s likely that your system is experiencing high levels of water contamination.

Water ingression can occur in two primary ways:

- Ambient humidity, which can ingress into the reservoir headspace and condense into the oil. Humidity can vary depending on the location and season, so pay attention to the conditions your equipment operates in and monitor your fluid condition accordingly.

- Pre-contamination of new fluid due to poor storage. Be sure to examine any new fluid for water contamination before introducing it into your hydraulic reservoir.

Liquid contamination in your hydraulic reservoir can cause a variety of serious problems, some irreversible.

You can expect the following if water contamination isn’t controlled:

- Due to its chemical composition and density differing from oil, water can affect compressibility, impacting operational efficiency.

- Water reduces oil lubricity and can lead to varnish buildup.

- Water can also cause corrosion and oxidization in the system. Cavitation and damage to metal surfaces in the system may lead to costly replacements and increased downtime.

Trust the Experts in Water Removal & Dewatering Filtration

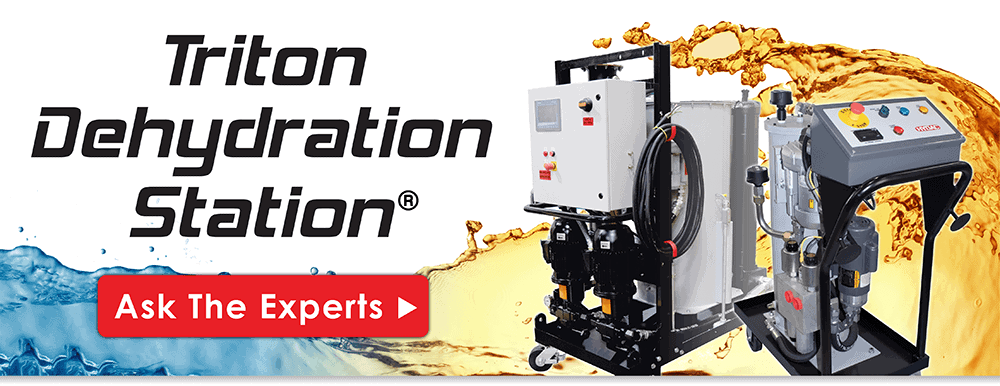

Schroeder Industries offers various products for targeting water contamination in hydraulic systems, backed by our vast expertise in fluid conditioning solutions. Our Triton Dehydrators, the TDSA and TDSE, bring proven performance across a wide range of applications where oil dehydration is needed.

The Triton Dehydration Station® series uses patented mass transfer dewatering technology to eliminate 100% of free water and up to 90% of dissolved water.

- Ambient air is conditioned to increase its water holding capability before injecting to the reaction chamber.

- Fluid is equally distributed and cascaded down through reticulated media and the conditioned air stream.

- Water is transformed to water vapor and is expelled from the unit as moist air/stream.

View the specifications of our TDSA and TDSE units below!

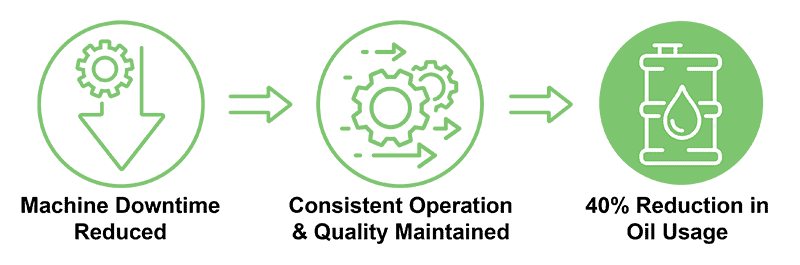

Schroeder Success: See How This Customer Saved!

Don’t just take our word on the effectiveness of the Triton Dehydration Station® series. Review the case study below to see how a real customer benefited from these advanced dehydrators!

Ask the experts at Schroeder Industries if a Triton Dehydration Station could be right for your application!

Contact-Blog-Triton Dehydrators

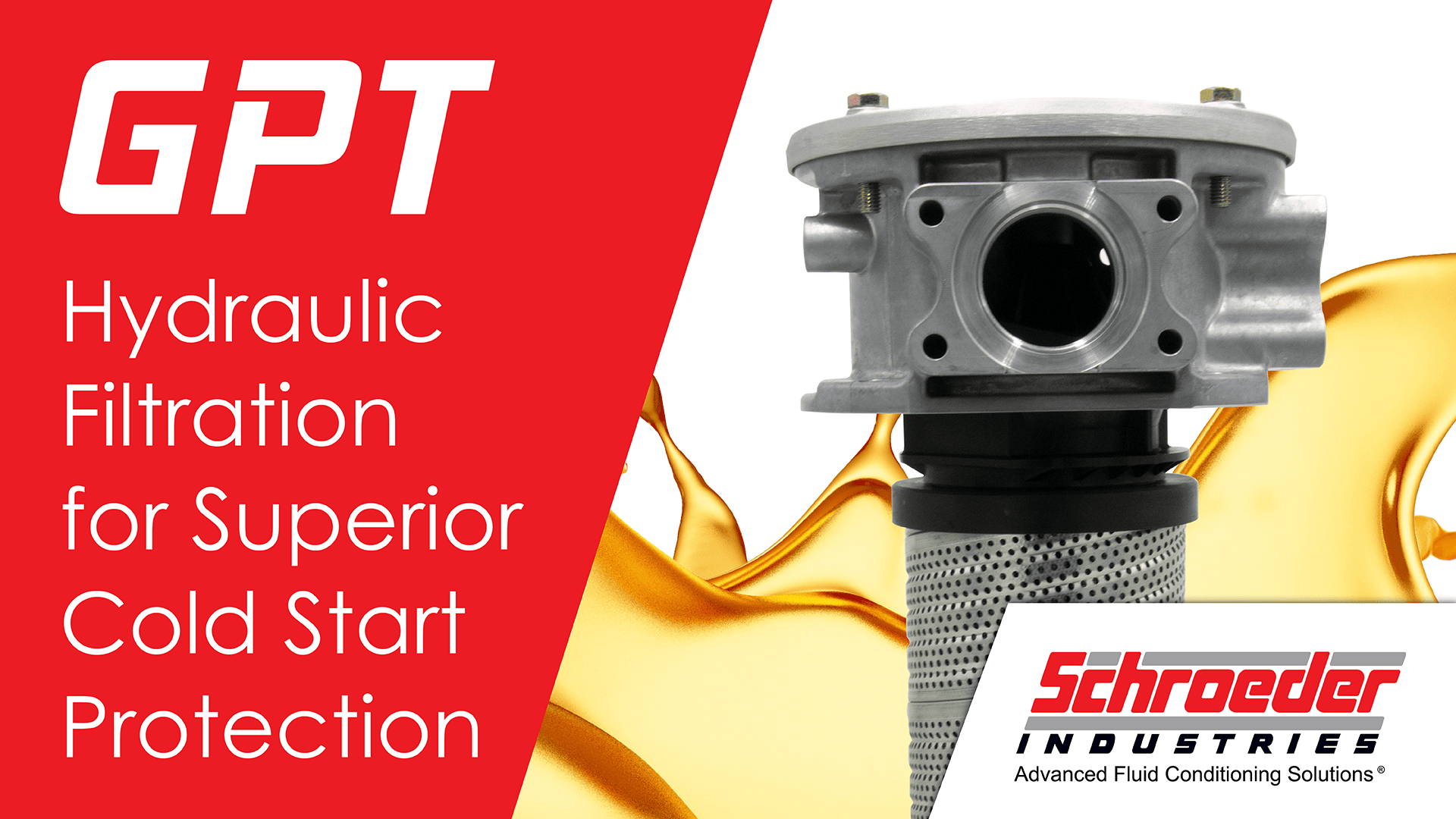

Introducing the GPT: Superior Filtration for Cold Start Conditions

Leave a Comment

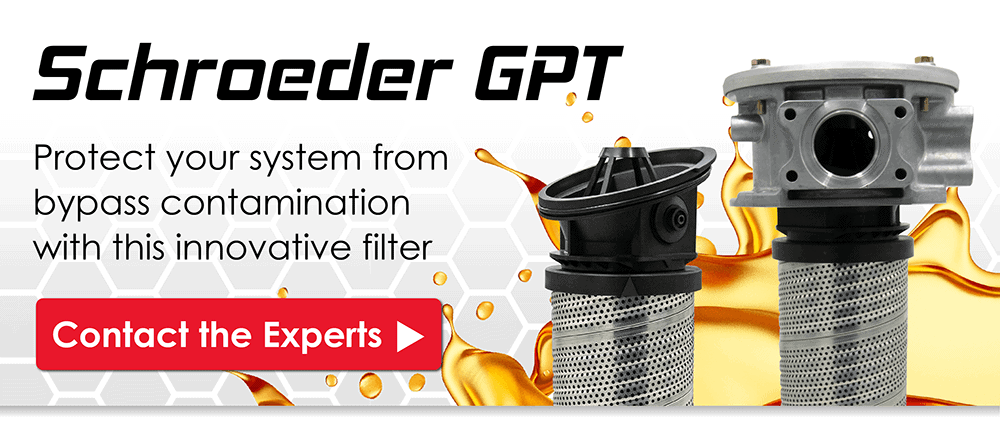

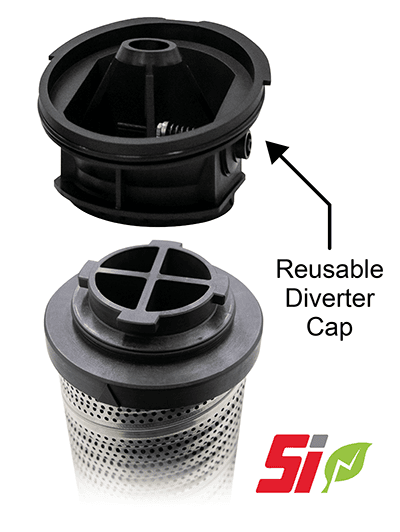

Schroeder Industries works tirelessly to provide innovative, effective filtration solutions. The GPT is a new hydraulic filter engineered to resolve a common problem with similar filters on the market: contamination from the bypass.

What makes the GPT the ideal hydraulic filter for cold start conditions?

When a hydraulic machine is shut down and the fluid stops flowing, contaminants will settle loosely onto the filter.

In cold start conditions, when the viscosity of the hydraulic fluid increases, the high differential pressure will force the filter into bypass. Until the machine and fluid warms up, thus lowering the viscosity, the fluid will bypass the filter and enter the hydraulic system directly.

Competitive filters currently available in the market have the bypass located low or within the element, where contaminants have settled during shutdown. If the system starts in bypass, all of that dirt is forced into the system without being filtered, flooding the system with harmful contaminants.

Unlike these other filters, the GPT bypass is located up top, in the diverter cap. This keeps the contaminants settled in the bottom of the filter from entering the system through the bypass.

Reusable diverter cap reduces landfill waste for a more sustainable filter design.

An unfortunate reality of filtration is the disposal of used elements, which contributes to the waste stream.

Keeping with the principles of our Energy Sustainability Initiative, Schroeder Industries is always looking for more sustainable angles in our product designs.

Our engineers saw the opportunity to reduce waste in our GPT design by developing a reusable diverter cap. Typical filters discard the diverter cap along with the filter element, but the reusable GPT design reduces the amount of waste material being disposed of.

With the GPT, element changeouts are fast and easy, and the Lock & Key Quality Protection ensures that only the highest-quality elements are being used.

Contact the experts at Schroeder Industries

Interested in the new GPT filter? Contact our filtration experts for more information!