Schroeder Industries & Portable Fluid Condition Monitoring

For a complete listing of Schroeder Industries Portable Fluid Sampling Systems, click here.

Schroeder Industries believes in gathering real-time oil analysis information to make informed maintenance decisions.

The technology made available to you typically comes in either permanently installed or portable units.

It is now possible to see the type and the amount of contamination in your system in real-time!

Schroeder’s portable sensors measure both particulate and water contamination. If fine particles are introduced to the system, both forms of contamination can be detrimental to the design and manufacturing of the heavy equipment you are using.

Additional technology included in our units gives representative samples and shape and size recognition to the types of fine particulates present and remaining oil life of the sample. Contamination values are calculated and shown in real-time on the integrated display, saving you the time and money versus sending to oil test labs and using unintuitive oil analysis kits.

Request More Information – Portable Fluid Sampling System

Request for Quote

What Is Contamination?

Contamination is anything that does not belong in a hydraulic fluid and can be a solid, liquid, or gas.

Types of Contaminants In Hydraulic Systems

- Air Bubbles

- Free Water

- Dissolved Water

- Debris

- Dust

- Sludge

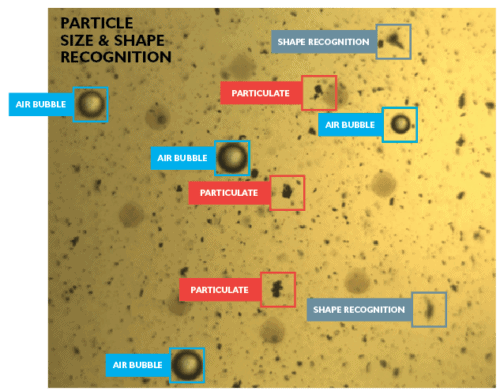

More recently, a new type of contamination has been detected when using light blockage particle counters…”phantom particles”. Several Schroeder units now include digital imaging technology to eliminate these phantom particles from the ISO count.

Make sure to read our blog post on overcoming these Phantom Particles.

The Schroeder Difference

Where this page is primarily focused on our portable contamination monitors, other options can be installed permanently on a system.

The convenience of being able to move a monitoring system is a major benefit.

Being portable makes these units easily accessible for use in routine contamination monitoring to troubleshooting and servicing a hydraulic system.

The Portable Fluid Contamination Monitoring units include the FCU1310 series, and the Schroeder Pro: Total Fluid Life and Total Fluid Health solutions.

FCU1310 – Fluid Control Units

- Used for temporary measurement of the solid contamination (ISO4406), water contamination, and fluid temperature in real-time with data immediately displayed.

- The FCU1310 is compatible with most mineral-based and synthetic fluids.

- Portable particle counter with saturation and temperature sensor.

Schroeder Pro: Total Fluid Life (TFL)

- Incorporates an oil condition sensor to provide the overall condition of the oil.

- Enables the oil’s remaining useful life to be determined relative to an included database. This database includes over 500 commonly used hydraulic oils.

- The TFL also measures solid contamination, water contamination, and fluid temperature.

- Compatible with most mineral-based, synthetic, and organic fluids.

Schroeder Pro: Total Fluid Health (TFH)

- Provides an insight into the real-time condition of your oil.

- Combining ISO4406 particle counts with digital camera / imaging particle counting, a more complete analysis of fluid condition can be realized.

- Digital imaging sorts solid contaminants and air bubbles into specific categories (fatigue wear, sliding wear, cutting wear, and fibers). This facilitates root-cause investigation. When coupled with the oil life and water saturation sensors, the health of your fluid is immediately known.

- The TFH is compatible with most mineral-based, synthetic, and organic fluids, diesel fuel. This includes complex fluids such as engine oil. As well as fluids containing high concentrations of insoluble additives, such as insoluble anti-foaming agents.

- Power Generation

- Industrial Hydraulics

- Wind Power

- Steel Making

- Off Road Mining & Construction

- Marine

Watch on YouTube “Schroeder Pro Series (Life+Health) | Oil Sampling & Analysis | New Product Release”.

Watch on YouTube “How to use the Schroeder Pro (Life+Health)”.