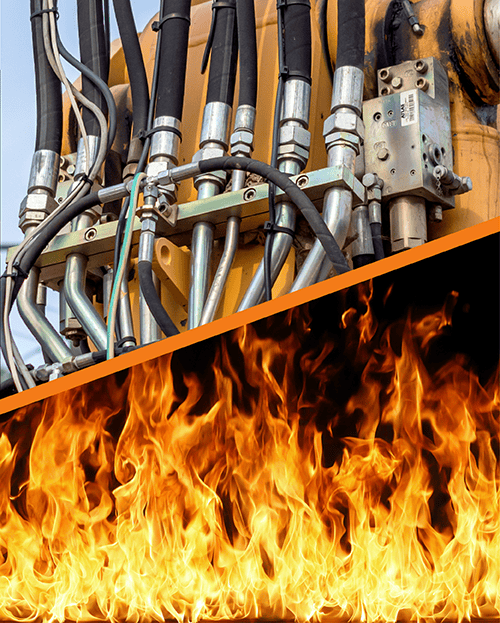

Equipment Feeling The Burn? Fix It With Filtration.

Leave a CommentEffects of Overheating on Hydraulic & Lubricating Systems Rising temperatures during the summer months can make working conditions tougher for everyone, including machinery. When equipment overheats, it can have serious effects up to and including catastrophic failure. This is due to two primary consequences of overheating: reduced oil viscosity, and accelerated oil degradation. Reduced Oil […]

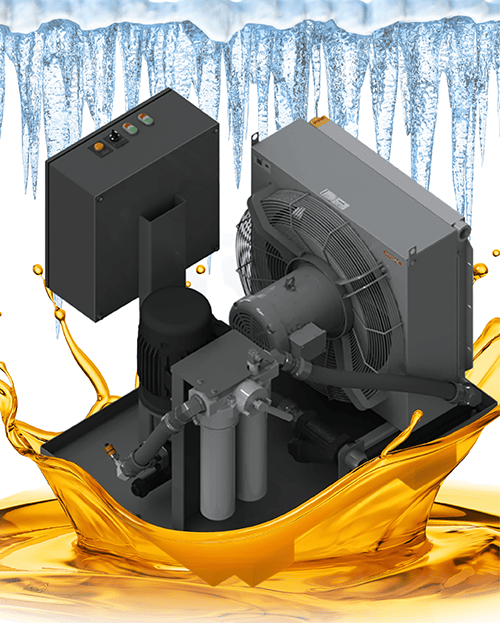

Is Overheating Grinding Your Gears? Try the Gearbox Cooling Skid.

Leave a CommentWhat is a gear box? Gear boxes are a fundamental part of many industrial and mobile machines. They consist of an enclosed gear assembly used to change torque and speed between a drive (e.g. a motor) and a load. These systems are frequently used in any power transmission application with rotary motion that requires a […]

It’s Time To Modernize Your Maintenance Strategy

Leave a CommentThe best way to deal with issues in your fluid power operation is preventing them from happening in the first place, right? Just change your oil or fluid regularly, problem solved. Not so fast. Focusing solely on a preventative maintenance strategy could be costing your business unnecessary time and resources! Predictive maintenance, on the other […]

Filtration for a More Sustainable Operation

Leave a CommentThere’s no sugar coating it: Industrial operations account for a large portion of CO2 generated by human activities. In recent years, industrial operations globally accounted for nearly ¼ of carbon emissions. As a result, many companies and operations have established sustainability goals with the aim of cutting emissions and waste associated with their activities. However, […]

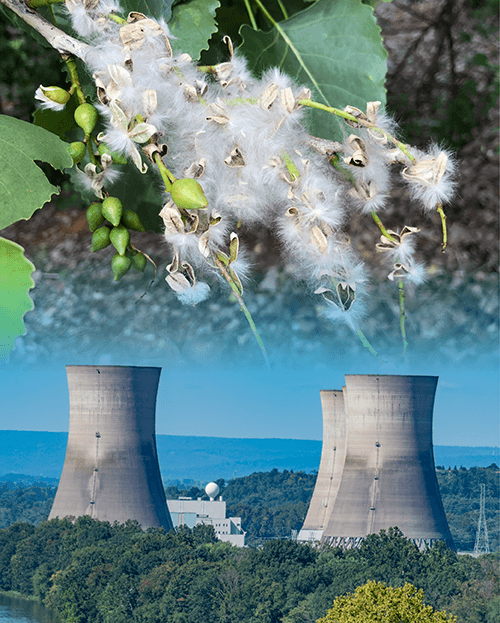

Protection from Cottonwood: What You Need To Know

Leave a CommentSpring is officially here, and while many welcome the warmer weather, spring conditions can bring higher risks of contamination. (And no, we’re not just talking about allergens!) One specific phenomenon, ‘cottonwood season,’ poses a particular risk for industrial operations using cooling towers, open loop systems, and other process fluid systems exposed to the outside air. […]

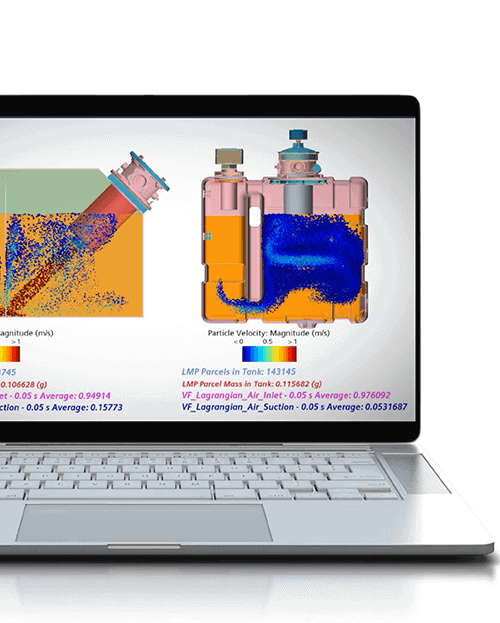

Tank Optimization: Revamp Your Reservoir!

Leave a CommentDo You Know What’s Happening In Your Hydraulic Tank? It may surprise you to hear that many hydraulic reservoirs are oversized and inefficient! Tank Optimization can give you important insights into how fluid moves inside your reservoir, and put you on the path towards a more efficient, cost effective, sustainable machine. What Is Tank Optimization? […]

Small But Mighty: Introducing the TNK1C Reservoir

Leave a CommentTNK1C: The Latest Addition to the TNK Family Schroeder Industries’ most compact hydraulic reservoir yet! Not Your Average Rotomolded Reservoirs Steel isn’t the be-all, end-all of hydraulic tanks. Schroeder’s TNK Series are expertly engineered for high filtration and deaeration performance, exceptional durability and a high standard of cleanliness all while being less energy-intensive to manufacture […]

Shape Up Your Filtration in the New Year

Leave a CommentThe new year is often a time when people set resolutions for self-improvement. It’s also the perfect time to improve your equipment performance! Filtration is the underlying process that keeps diesel and hydraulic-driven equipment moving. Schroeder Industries offers proven solutions that help your equipment perform at its best. Here are just a few of the […]

Au Revoir, 2024: A Year of Growth & Innovation

Leave a CommentIt’s hard to believe, but 2024 is almost over. So much happened this year at Schroeder Industries, here’s some of the highlights! Schroeder Industries Leetsdale Expansion 2024 was a year of significant changes for Schroeder Industries headquarters, located in Leetsdale PA. In late 2023, the process of acquiring an addition 40,000 square feet for the […]

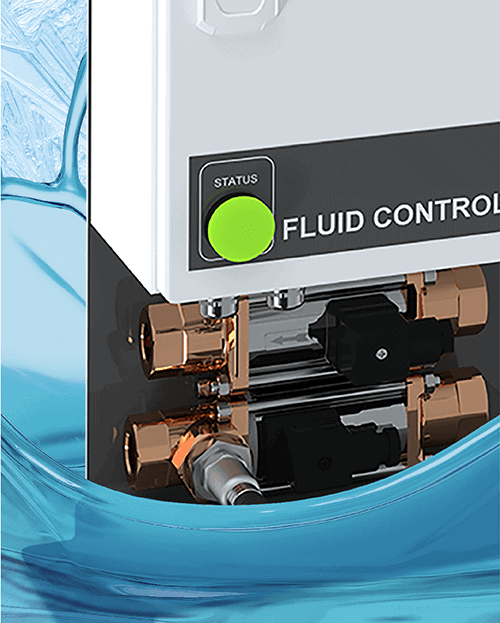

Coolant System Monitoring Just Got Simpler

Leave a CommentCoolant systems are a staple at virtually all major manufacturing and power plants, protecting the vital equipment resources from the effects of overheating. However, maintaining a coolant system is incredibly time consuming. With any coolant system, the operator needs to perform daily checks of the tank volume, adding fresh emulsion if necessary. Manual checks of […]