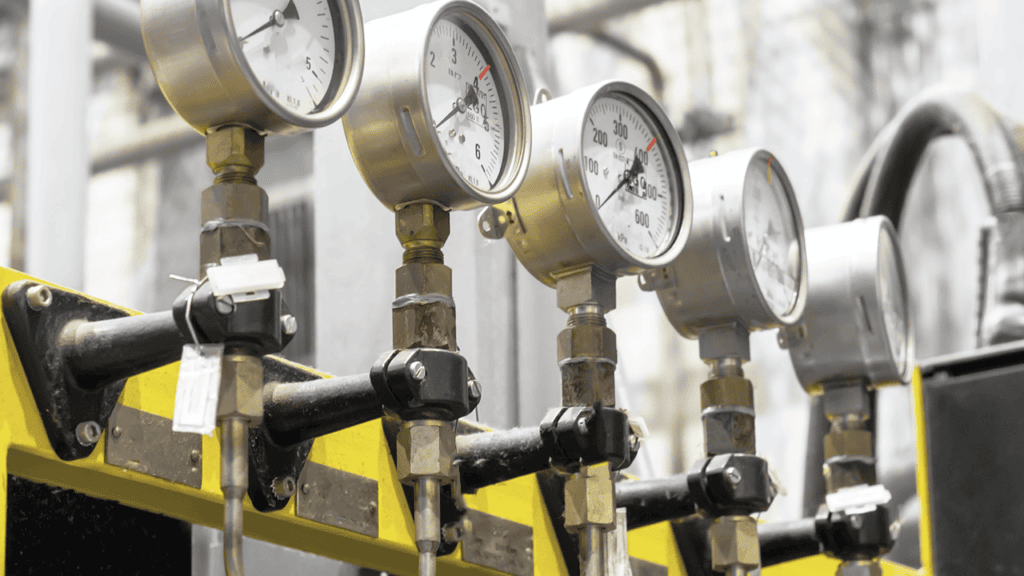

Hydraulic, Diesel, Process Fluid, and Compressed Gas Filtration Solutions for Industrial Equipment

A huge variety of industries utilize hydraulic and diesel-powered equipment for manufacturing, processing, refining, and other industrial processes.

Schroeder Industries engineers filtration solutions that keep these vital machines moving!

Find Schroeder Industries Filtration Solutions For:

Featured solutions for your fluid conditioning and filtration needs!

Pulp & Paper Industry Case Studies

TDS-E Saves Pulp & Paper Manufacturer $10K Per Month In Oil-Related Expenses

A manufacturer in the pulp & paper market required additional water removal capacity, as their current dehydrator units were not able to keep up with the quantity of water ingression into their power generation turbine reservoir.

Through Schroeder Industries’ rental program, a TDS-E unit was provided. The unit proved so successful that the customer ultimately purchased the unit outright.

Here’s how the TDS-E benefited this customer:

Rental Program Provides Affordable, Immediate Treatment

Exceptional Oil Recovery With Minimal Maintenance

$10,000 Saved Per Month On Oil-Related Expenses

Schroeder SBF Elements Resolve Press

Downtime Issues for Automotive Manufacturer

A manufacturer of automotive, marine, and other vehicle market components struggled with downtime across multiple plants.

Analysis revealed that the customer’s non-Schroeder filtration was not reaching the appropriate ISO targets. By utilizing Schroeder Industries BestFit® elements, the filtration performance increased dramatically.

Here’s how BestFit® elements benefited this customer:

~20-30% Increase in Element Dirt Holding Capacity

5x Increase in Filter Element Efficiency

ISO Code Targets Reached, Reducing Downtime

Coming Soon.

You could be Schroeder’s next success story! Let us know how we can help.

How can we improve your filtration & equipment performance? Ask the experts!

Request a Quote:

Ask the experts!