Lower your carbon footprint with Schroeder’s GREEN, “eco friendly” Electric Drive (E-Drive) Media Filtration Technology.

For a complete listing of Schroeder Industries‘ Filter Elements, click here.

As electric hydraulics continue to advance in the mobile hydraulics industry, methods of improving the energy efficiency of these electric systems is top priority. Already, electric hydraulic systems show great promise in beating traditional hydraulic systems in energy efficiency.

So, how do we capitalize on saving energy and increase the efficiency of electric hydraulic systems?

The answer: Minimize the pressure drop.

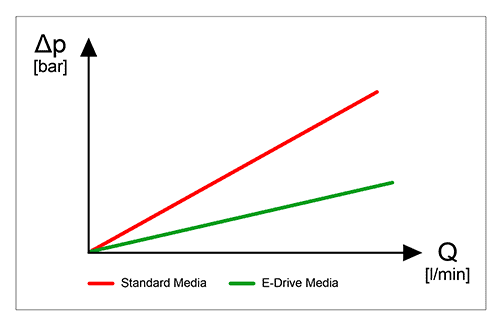

Pressure Drop Reduction = Improved Energy Efficiency

Energy comes at a cost, so wasting energy is literally throwing money away. Therefore, it’s critical to refine system efficiency and ensure that as much of the energy input as possible is available to do useful work.

When determining the energy of efficiency of a hydraulic system, differential pressure is a key metric. Differential Pressure describes the loss of available energy in a hydraulic system—although the energy is not technically ‘lost’, but converts to thermal energy, which does not contribute to the system’s function.

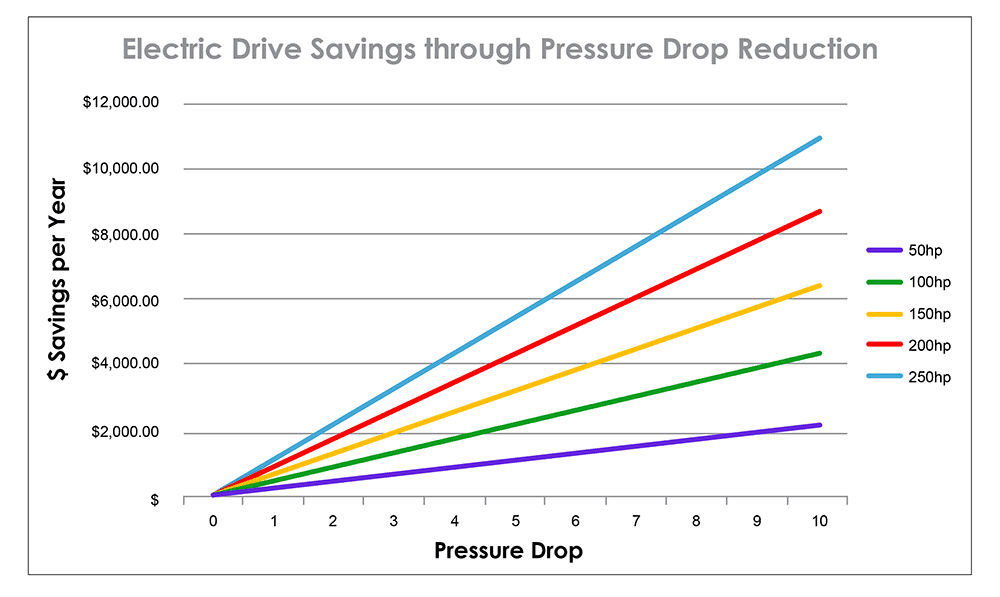

For example, even a relatively small pressure drop in a high horsepower system forces the pump/motor group to work harder and make up for the loss of energy. This reduced efficiency, and the degradation of component parts due to stress, means increased costs associated with energy usage and part repair or replacement. Take a look at how lowering pressure drop by even a few psi can save money:

So how do we lower the overall pressure drop in an electric hydraulic system? That is where Schroeder’s Electric Drive media can help.

Electric Drive Media from Schroeder Industries

For safe, reliable, energy efficient equipment operation, look no further than Schroeder’s Electric Drive (E-Drive) Media filtration technology.

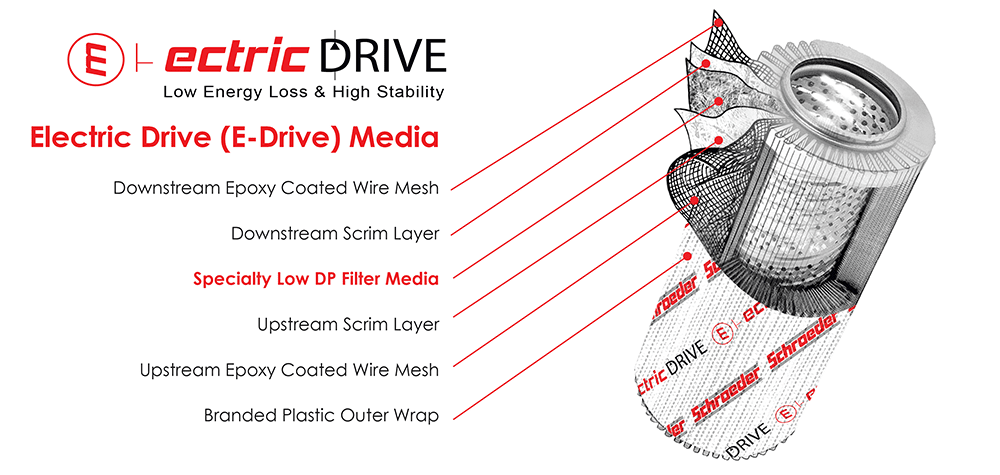

Filter elements built with all-new E-Drive media boast a low pressure drop, making them more compatible with low-energy requirements versus conventional hydraulic elements in the same ambient conditions. Depending on the application, E-Drive Media can lower the pressure drop significantly enough that consumers may even be able to downside their horsepower requirements, saving more energy and money!

E-Drive filter elements are made using an all-new specialty formulated, high efficiency, low differential pressure media. These elements are the ideal choice for hydraulic-drive motor-pump units, particularly in low-temperature conditions where cold start behavior occurs.

For saving on electric costs and wherever high-viscosity fluids are used, the properties of Schroeder’s E-Drive filter elements make them the clear choice. When tested against the typical synthetic microglass media currently available, our 10-micron Electric Drive Media element demonstrated a lower pressure drop factor.

Technical Specs (evaluated in K-sized element):

| Media Type | β200 [µm(c)] | Pressure Drop Factor [psid/gpm] |

| E-Drive Media (10 µ) | 10.2 | 0.050 |

| Typical Synthetic Media (10 µ) | 10.6 | 0.156 |

- Element Collapse Rating: 145 psid (10 bar)

- Temperature Range: -22°F to 212°F (-30°C to 100°C)

- Flow Direction: Outside to Inside

E-Drive Media is currently rated for 10-micron filtration, with other micron options available in the near future.

Could E-Drive Media be the solution for your electric hydraulic systems?

Email us at sisales@schroederindustries.com to discover whether Schroeder’s E-Drive Media could potentially increase your systems’ energy efficiency and save you money.

E-Drive Media is part of Schroeder Industries’ 2030 Initiative, a suite of filtration solutions and technology proven to support carbon neutrality goals. Learn more about how Schroeder Industries and sustainability go hand in hand!