Hydraulic, Diesel, Process Fluid, and Compressed Gas Filtration Solutions for the Refuse Market

From municipal waste collection, to landfills and recycling & processing plants, the refuse industry keeps our communities clean and healthy. Waste management companies utilizes a wide range of hydraulic and diesel-powered machinery, and Schroeder Industries engineers filtration solutions that keep these vital machines moving!

Find Schroeder Industries Filtration Solutions For:

Featured solutions for your fluid conditioning and filtration needs!

Refuse Industry Case Studies

Tank Optimization and BRT In-Tank Filtration Save 19 Gallons Per Unit for Refuse Industry OEM

An OEM manufacturing a variety of hydraulic refuse trucks

sought ways to improve the design and efficiency of their side

loader model. Schroeder Industry utilized Tank Optimization and BRT in-tank filtration to help downsize their reservoir!

Here’s how Tank Optimization and BRT filtration benefited this customer:

19 Gallon Volume Reduction, 335lbs Weight Reduction

Initial Oil Cost Savings of $380

450lbs Initial Carbon Dioxide Reduction

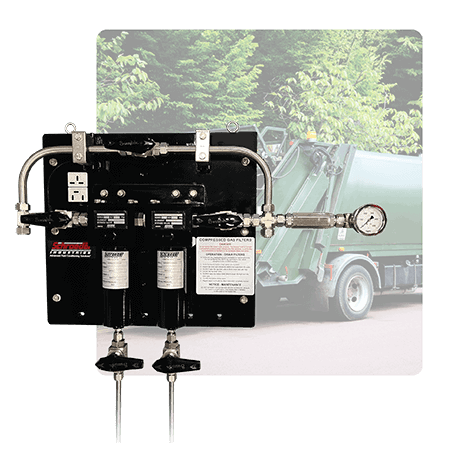

CGFP50 Reduces Maintenance & Installation Costs, Improves Element Supply Chain

An MRO in the refuse industry struggled to source high-quality CNG filtration elements in a timely manner and sought a more easily maintained slow-fill CNG filtration system. Schroeder Industries provided the CGFP50, an extremely effective, cost-saving solution!

Here’s how the CGPF50 benefited this customer:

$5k – $10k Estimated Savings on Installation Per Site

Estimated $10k Saved on Maintenance, Consumables Per Site

Potentially 6-figure Annual Savings Across All Fueling Sites

Schroeder Filtration Upgrade & Tank Optimization Reduces Downtime, Oil Usage

An OEM producing refuse collection trucks struggled with sticking valves, causing their side loader’s lift arms to jam when extended and requiring constant work stoppage for manual retraction. Schroeder Industries stepped in with a multi-faceted Tank Optimization and hydraulic filtration solution featuring the ART Tank-Mounted Filter and VF60 Top-Ported Pressure Filter.

Here’s how these Schroeder Solutions benefited this customer:

8 Gallon Oil Reduction Per Unit ($160 Oil Expense Savings)

Zero Additional Field Failures Documented Since Implementation

189lbs Carbon Dioxide Reduction Per Unit

Coming Soon.

You could be Schroeder’s next success story! Let us know how we can help.

How can we improve your filtration & equipment performance? Ask the experts!

Request a Quote:

Ask the experts!