Cartridge Housings and Elements from Schroeder Industries

For a complete listing of Schroeder Industries’ Cartridge Housings and Elements, click here.

Cartridge housings and Elements are a part of a complete process filtration system.

Schroeder provides a full line of cartridge filters and housings and depth filtration to fit.

What is Cartridge Filtration?

A cartridge is encased within a housing and used to remove unwanted particles, common air pollutants, and chemicals from liquids.

The cartridge is exposed to water, liquid or solvent that needs filtration. Filtration is needed as it flows inside the housing and passes through the filter element.

Cartridge filters can also remove submicron particulates.

Schroeder can provide surface or depth cartridges made of numerous materials depending on the liquid to be cleaned.

Standard cartridges are available in lengths from 10-40 inches.

These meltblown filters come in either a 2.5″ or 4.5″ diameter.

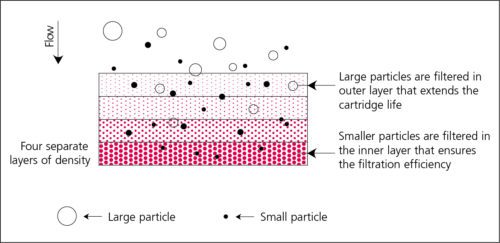

Depth filter cartridges have larger openings towards the outside of the element and smaller openings near the center. This allows for higher dirt holding capacity to lengthen the life of the element.

Filtration range for Schroeder cartridge elements start at 1 micron to 100 microns.

Ranging from Bag Type to High Purity Cartridges and Housings, Schroeder offers highest quality and cost saving options.

- Bag type can be convertible into most commercial bag filter housings.

- High surface area design providing longer service life.

- Tightly controlled manufacturing process ensuring consistent reliability for optimal filter performance.

- Large holding capacities for longer time between filter cartridge changes

Industrial Cartridge Filters are Widely Used in Industries Such As:

- Pharmaceuticals

- Chemicals

- Inks and paints

- Food and beverage

- Automotive manufacturing

- Cement industry

- Oil and gas

- Refineries

- Petrochemicals

- Membrane pre-filtration

- And even more

They are manufactured from polypropylene, polyester, nylon and other low cost durable materials. Using materials such as 100% pure polypropylene ensure high quality. The elements are disposable and easily changed, making them cost effective and supporting of Schroeder’s 2030 Initiative.

Learn more about Schroeder’s environmental impact here.

About Schroeder Industries

Schroeder Industries has years of of extensive industry expertise.

The quality of our products, services and product management are tailored to your needs.

Applications

Process Fluid Filtering:

Process fluid filtering is the purification of a fluid by the removal of unwanted solid material.

Process fluids include fluids used to cool or lubricate equipment.

In mechanical equipment, or during the processing of a fluid, particulate material can accumulate.

In order to maintain the purity of the fluid, the particles must be removed.

The oil filter in your vehicle is a good example of a cartridge filter.

It is being used to maintain the quality of a process fluid.

Watch on YouTube “BR | Bag Type High Flow Filter Cartridges | Process Filtration”.

Solids Removal/Recovery:

Another industrial application is in solids recovery.

Solids recovery is done to either recover desirable solids from a fluid or to “purify” the fluid. This is prior to subsequent treatment, use, or discharge.

For instance, some mining operations will use water to convey the minerals being mined from site to site. After the slurry arrives at its desired location, it is filtered to remove the desired product from the carrier water.

It’s Not Just Water We Process

Water processing is an extensive amount of what our bag housings and elements can handle. This is only the tip of the iceberg for what we filter.

Watch on YouTube “RBGC & MTX | Resin Bonded Filter Cartridges | New Product Release”.

Typical Products Filtered:

- Abrasives

- Adhesives

- Chemicals

- Cleaning Fluids

- Detergents

- Fabric Coatings

- Food Products

- Industrial Coatings

- Juices

- Liquids of all types

- Paints

- Petroleum Products

- Pharmaceuticals

- Printing Inks

- Process Water

- Roller Coatings

- Textile Chemicals

- Vegetable Oils

- Vinegar

- Waxes

- And more!

Schroeder Industries has long been known for innovation to meet customer needs.

Contact the factory if you have an application that requires special consideration and designs.

The Schroeder Guarantee

Schroeder ensures protection of product and equipment, no matter what the project.

To do this, it is important to perform selective filtering of solids from gas and liquid process streams.

Poor filtering can cause a degradation of your final product or failure of equipment.

This can cause hundreds of thousands or millions of dollars in downtime or wasted product.

An infinite amount of applications and gases/liquids exist and Schroeder has the expertise to determine your optimal filtration needs. Schroeder has the optimized filtration solution based on your media, economics, permits, filtration goals, etc. This can include industrial processes, mining food and beverage, drinking water and wastewater.

For a complete listing of Schroeder Industries’ Cartridge Housings and Elements, click here.