What Is The Deaeration Process?

For a complete listing of Schroeder Industries’ Tank Deaeration Filters, click here.

Deaeration is the removal of air molecules from another gas or liquid.

If you were to look up this question online, the search results would display endless links and theories about what makes this technology possible.

With us being one of the results you have found, allow us to take it from the top (or bottom depending on your machine’s porting preference).

With global competition continuously placing strong pressure on OEMs (original equipment manufacturers) to decrease costs and increase energy efficiency, it is tough to install additional engine components in the already limited design space around the hydraulic tank.

Manufacturers like Schroeder Industries needed to pivot towards the flexibility in reservoir accessories and components. Anything to support an overall system size decrease is what equipment manufacturers need the most.

One major area we noticed for immediate improvement was the filter.

In our experience, hydraulic tanks are often times oversized and flooded with extensive baffles and components in the hopes to dissolve oxygen and reduce the amount of time to remove particulate matter.

But what if the filter, an already permanent resident in a hydraulic tank, could serve dual functions (act as two) and allow for a removal of unnecessary components thus resulting in a true storage tank size reduction?

Introducing Schroeder’s Line of Next Generation Tank Deaeration Filters

Our all-new line of Tank Deaeration Filters are your answer for a true removal of oxygen content within your hydraulic fluid.

Changes in design engineering driven by the market and the resulting space increase for new components are among the many factors Schroeder is mindful of.

In every existing tank system, Schroeder sees the opportunity of optimizing and reducing the tank one component at a time.

The first step: a literal overhaul of the in-tank filter.

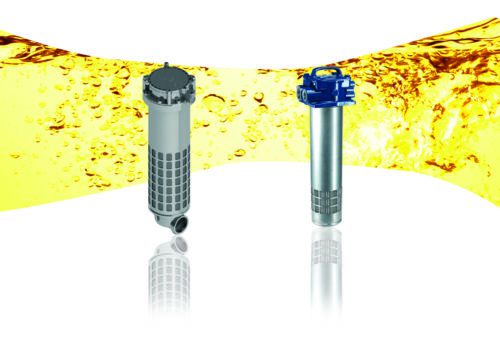

Our brand new BRT (base-ported) and TRT (top-ported) Return Line Filters are the perfect companion on your tank optimization journey.

Each filter product includes our patented deaeration equipment technology:

BRT – Return Line Filter

- Filter is mounted in the tank and flow comes to it from a pipe connection below it or from the side

- Patented deaeration windows around the housing offer superior air bubble coalescence in a 360 degree discharge

- Quality protected inside-out flow element design

TRT – Return Line Filter

- Filter head is mounted on the tank like a standard return-line filter solution

- Patented deaeration windows around the housing offer superior air bubble coalescence in a 360 degree discharge

- Quality protected element design

Find hydraulic parts near me

Watch on YouTube “BRT & TRT Filters | Next Generation: Tank De-aeration | New Product Release”.

As a refresher, further Hydraulic and Lube Filtration education can be found here.

Fewer Particles Means Higher Quality

It is a goal to always achieve completely clean oil. The quality of oil depends on the absence of contamination. That includes larger particles, particulate, liquid, and air contaminants.

The BRT & TRT products naturally help with liquid and particulate filtration, but removal of air particles takes further consideration.

In general, how fluid enters the reservoir would impact the excessive air particles that can be introduced into the system. Combined with insufficient dwell time of the fluid, there would not be enough time for air particles to dissipate.

At Schroeder, we analyze oil storage as a system and treat the reservoirs with the respect it deserves.

Schroeder looks at the overall volume of the container. We also look at internal baffling, geometry, contour, flow velocity, and system performance profile.

There are ways to increase fluid dwell time within the reservoir, to maximize the internal space without requiring excessive storage dimensions.

By utilizing innovative design of the reservoirs, we are able to reduce the footprint of fluid storage. We achieved this without compromising dwell time inside the reservoir. Schroeder can modulate fluid entry velocity and profile. This grants us ability to tamper the disturbance created through entry and allow fluid to settle in a controlled manner.

How Can Schroeder Assist with Deaeration?

In order to achieve these deaeration functions, Schroeder Industries offers a vast array of products and services. These range from tank redesign, innovative filter housing products, and fluid monitoring devices. Sometimes a customer needs a component change or a system redesign to improve the deaeration performance on their machinery. Schroeder has a solution.

Watch on YouTube “The 7 Steps to Choosing the Correct Filtration”.

For a complete listing of Schroeder Industries’ Tank Deaeration Filters, click here