In recent years, sustainability and carbon emission reduction have become hot topics across the globe.

Industrial carbon emissions account for approximately one quarter of total carbon emissions in the United States alone. Reducing these emissions is a necessary, yet complicated process that requires effort and innovation from all corners of industry, with every sector having a unique part to play.

Sustainability and Schroeder: How They Go Hand in Hand

Since our origins as a mining distributor in 1946, Schroeder Industries always saw the need to rid the world of harmful practices tied to energy consumption.

Filtration is an overlooked, yet important tool in the greater conversation about sustainability. For example, contamination in a hydraulic system impacts energy efficiency and reduces the operational lifespan of its components and hydraulic fluid, consuming more energy and contributing to the waste stream. Additionally, proper fuel filtration can significantly reduce harmful emissions and increase fuel efficiency. These, among other industrial issues addressed by filtration, can have a great net impact on an operation’s carbon footprint.

As a leader in developing, manufacturing, and implementing exceptional filtration solutions, Schroeder Industries aims to empower industrial operations with sustainable filtration systems.

What is Schroeder Industries’ Energy Sustainability Initiative?

The Energy Sustainability Initiative is Schroeder Industries’ mission to provide fluid power filtration solutions that contribute to a cleaner world and help organizations reach their sustainability goals. Here’s how:

- By supporting emerging clean energy technology, including electric and hydrogen gas powered systems, with optimized filtration solutions.

- By reducing wasted hydraulic oil and increasing the energy efficiency of hydraulic systems with advanced filtration and diagnostic solutions.

- By increasing diesel fuel efficiency and reducing carbon emissions through superior fuel filtration.

- By engineering innovative alternatives to current wasteful and inefficient filtration technology.

Energy Sustainability Initiative Solutions

Read on to learn how each product group contributes to the overall Energy Sustainability Initiative mission. Click here for a more comprehensive list of products within the initiative.

Filter Element Technology

Filter elements are at the heart of every hydraulic filtration system. Protecting equipment from damaging contamination, which reduces efficiency and degrades system components, requires a high-quality filter element. Greater efficiency through effective filtration means lower energy consumption, and longer component life means less wasted material—both important factors in an operation’s carbon footprint.

Featured Filter Element Solution:

Hydraulic & Lube Filters

Together with our high-efficiency filter media, Schroeder’s hydraulic filters are engineered to enhance system efficiency, increase oil longevity and even enable reservoir downsizing in certain cases. This contributes to a lighter and more efficient system overall, and reduces steel and oil usage.

Featured Hydraulic & Lube Filtration Solutions:

Hydraulic Accessories

Our signature, highly customizable TNK line is manufactured with highly recyclable HDPE for a lightweight, extremely durable reservoir solution. They require less energy to produce than a comparable steel tank, and the reduced weight contributes to overall system and energy efficiency.

Featured Hydraulic Accessories Solution:

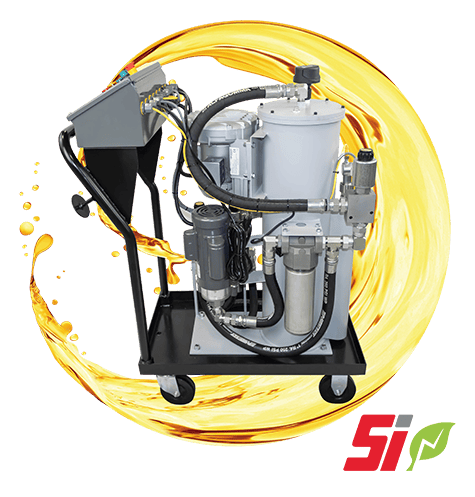

Filter Systems & Diagnostics

Due to contamination, hydraulic oil is often disposed of before its usable life is up. Using diagnostic tools and high-quality offline filter systems is a great way to monitor fluid health and extend the life of hydraulic oil, substantially reducing waste. Additionally, taking proactive measures to detect and reduce hydraulic contamination benefits machine efficiency.

Featured Filter Systems & Diagnostic Solutions:

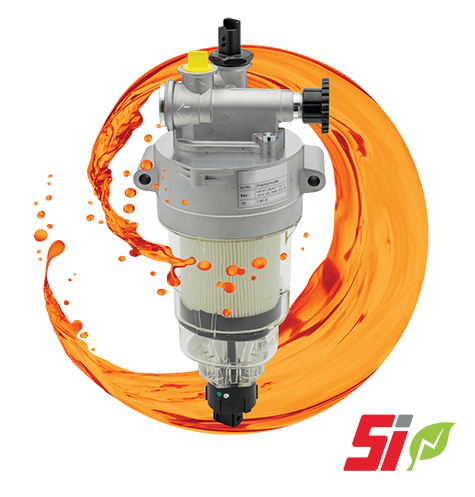

Fuel Filtration

Most on and off-highway equipment continues to rely on diesel fuel, underscoring the need for premium fuel filtration products. Proper diesel fuel filtration increases fuel efficiency and gas mileage and reduces emissions by removing contaminants and enabling clean combustion. Schroeder also provides filtration solutions that support lower emission, compressed natural gas.

Featured Fuel Filtration Solutions:

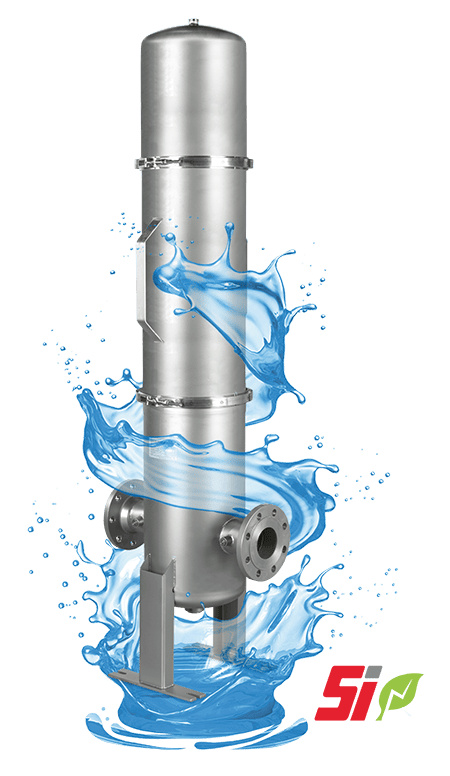

Process Filtration

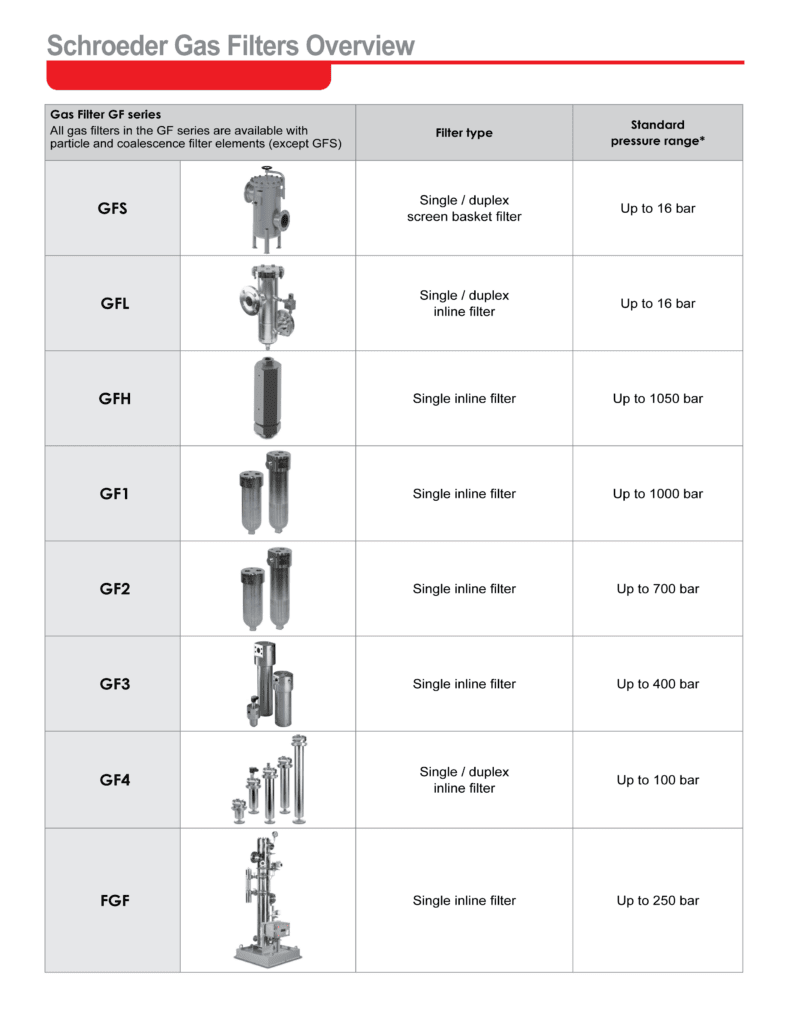

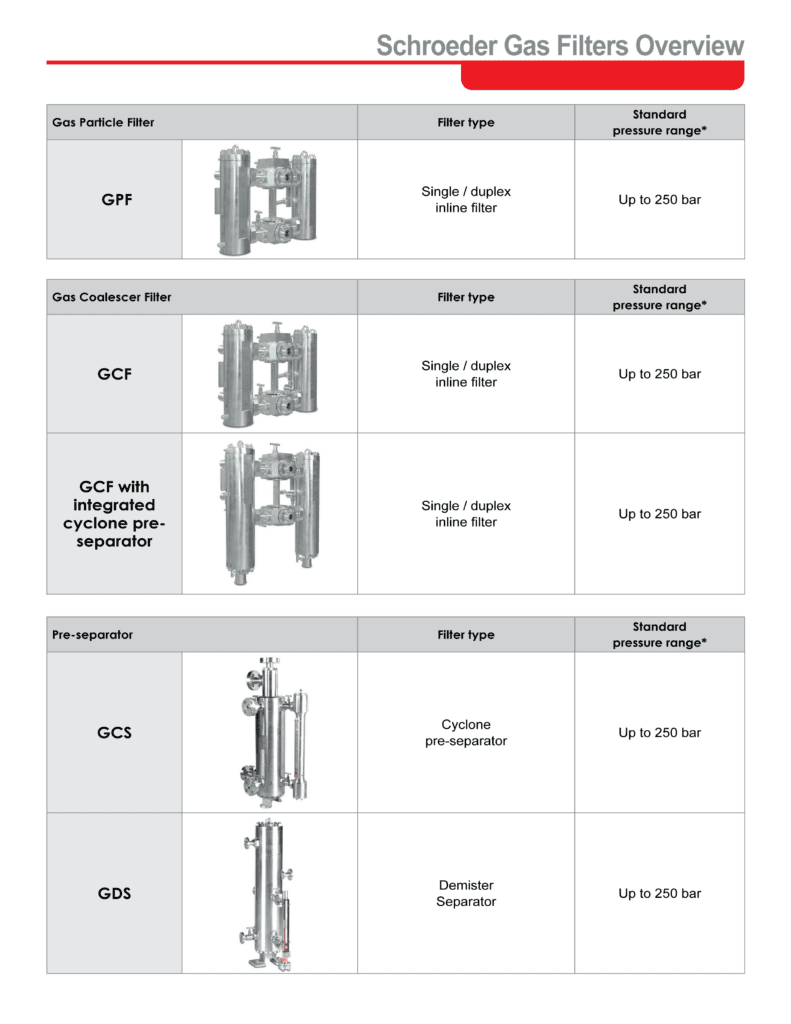

Conserving and recycling water resources is vital for sustainable practices across a range of industries, and effective water filtration systems play an important role. From wastewater treatment and irrigation to cooling towers and marine ballast applications, powerful filtration is required to keep water clean & downstream equipment protected. Our Process Filtration division also offers premium hydrogen gas filters for systems powered by clean, renewable hydrogen.

Featured Process Filtration Solutions:

Try out Schroeder products to achieve your oil cleanliness goals, save money, and reduce your carbon footprint:

Schroeder Rental Equipment Program

Enjoy the benefits of Schroeder Industries’ exceptional filtration equipment without a large capital investment. Superior filtration extends oil life and increases machine reliability and energy efficiency for a more sustainable operation.

Filtration Management as a Service (FMaaS)

With this turnkey service, Schroeder Industries will plan, execute, and manage your filtration strategy and filtration equipment. Reduce your carbon footprint by extending your oil life and eliminating the emissions associated with repeat oil recycling truck visits.