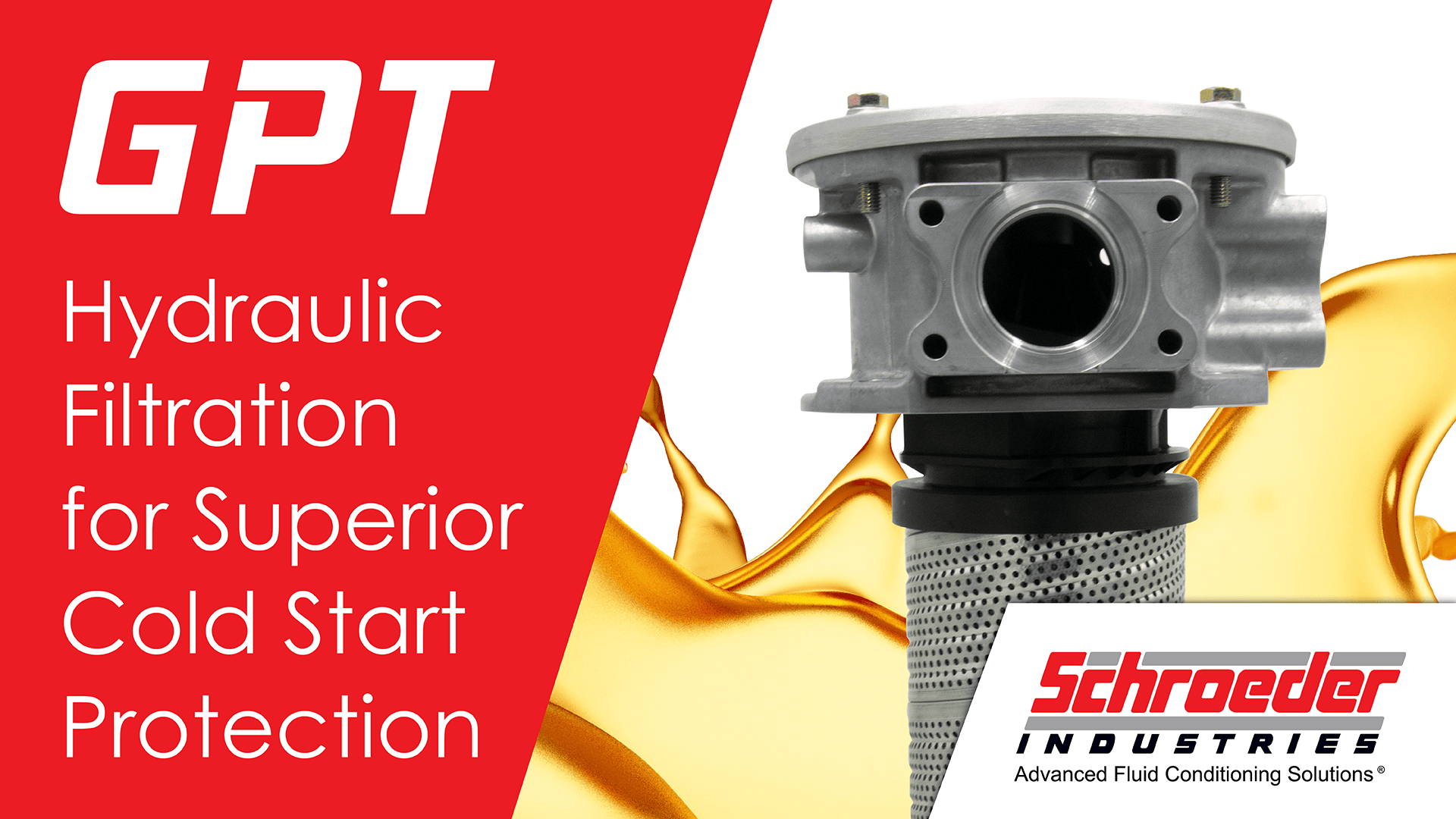

Schroeder Industries works tirelessly to provide innovative, effective filtration solutions. The GPT is a new hydraulic filter engineered to resolve a common problem with similar filters on the market: contamination from the bypass.

What makes the GPT the ideal hydraulic filter for cold start conditions?

When a hydraulic machine is shut down and the fluid stops flowing, contaminants will settle loosely onto the filter.

In cold start conditions, when the viscosity of the hydraulic fluid increases, the high differential pressure will force the filter into bypass. Until the machine and fluid warms up, thus lowering the viscosity, the fluid will bypass the filter and enter the hydraulic system directly.

Competitive filters currently available in the market have the bypass located low or within the element, where contaminants have settled during shutdown. If the system starts in bypass, all of that dirt is forced into the system without being filtered, flooding the system with harmful contaminants.

Unlike these other filters, the GPT bypass is located up top, in the diverter cap. This keeps the contaminants settled in the bottom of the filter from entering the system through the bypass.

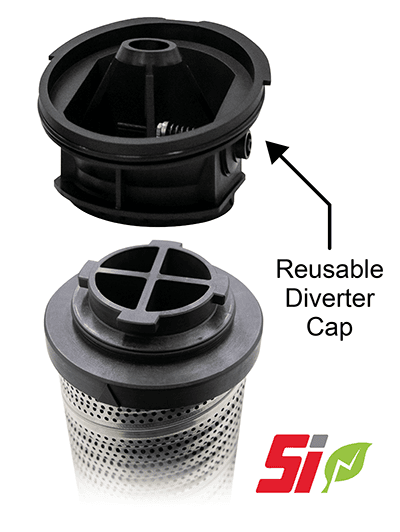

Reusable diverter cap reduces landfill waste for a more sustainable filter design.

An unfortunate reality of filtration is the disposal of used elements, which contributes to the waste stream.

Keeping with the principles of our Energy Sustainability Initiative, Schroeder Industries is always looking for more sustainable angles in our product designs.

Our engineers saw the opportunity to reduce waste in our GPT design by developing a reusable diverter cap. Typical filters discard the diverter cap along with the filter element, but the reusable GPT design reduces the amount of waste material being disposed of.

With the GPT, element changeouts are fast and easy, and the Lock & Key Quality Protection ensures that only the highest-quality elements are being used.

Contact the experts at Schroeder Industries

Interested in the new GPT filter? Contact our filtration experts for more information!