Mitigating fluid contamination is a chief concern for hydraulic systems. Solid, liquid, and other forms of fluid contamination account for up to 90% of all hydraulic system failures. Water, ingested particulate contamination, and metal particles from internal component wear are just a few types of contamination. Contamination is influenced by ambient conditions and other variables, and can have serious impacts on hydraulic equipment performance.

Contamination cannot be completely stopped, but proper fluid filtration can prolong the lifespan of your hydraulic components—and a successful treatment strategy begins with accurate diagnostics.

Portable Fluid Condition Monitoring

To make fluid assessments more convenient, Schroeder Industries developed several portable fluid condition monitoring systems. These compact units are designed to deliver real-time insights into the health of a variety of hydraulic fluid types. On-site analysis with a portable condition monitoring unit saves time and money compared to shipping samples to oil testing labs, or using complicated analysis kits. Their portability makes them usable in the field, in remote locations, along a manufacturing process production line—anywhere a hydraulic system can be found.

Introducing Total Fluid Condition (TFC)

The new TFC unit represents the latest in fluid condition monitoring technology. This revolutionary portable service unit is designed to measure and differentiate particulate contamination, as well as relative water content and temperature.

Improving Contamination Data Accuracy

Correctly identifying the type and source of hydraulic fluid contamination is critical for developing a treatment strategy. The TFC unit improves upon the accuracy of fluid contamination data in synthetic and mineral oil based hydraulic fluids, offering users a more complete analysis of their fluid health than was previously possible. This improved precision stems from the new direct digital imaging sensors incorporated into the TFC units.

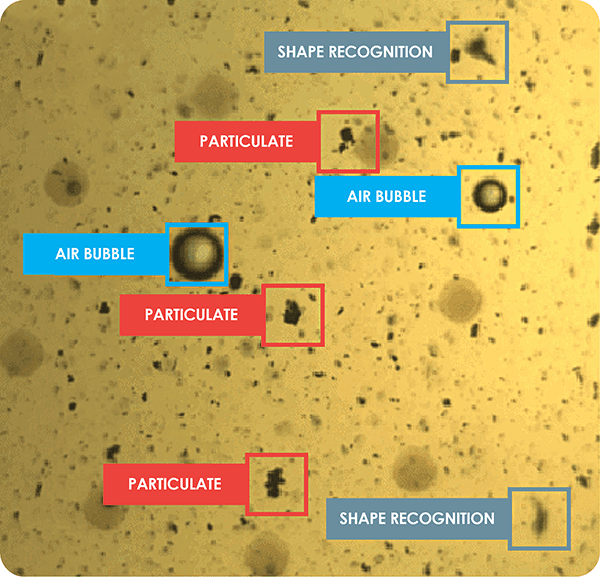

Other portable fluid contamination monitoring units have utilized light-based sensors, which struggle to differentiate between contamination types, but direct digital imaging sensors can distinguish air bubbles and water molecules from solid particles. This results in a more accurate ISO count, and better understanding of the fluid’s health.

The TFC can also sort particles into fatigue, cutting, sliding wear, and fiber categories to estimate cause of contamination. The direct imaging particle counting software coded into the unit uses size and shape-recognition technology, based on advanced algorithms, as a dirt classifier to distinguish contaminates.

TFC Applications

Like Schroeder’s other portable fluid diagnostics systems, TFC is a powerful, versatile tool for any fluid cleanliness testing scenario:

- Perfect for in-plant/industrial applications, during the assembly process or at the end of the production line.

- The compact design and onboard battery also make the TFC ideal for mobile applications, such as testing for service trucks or in remote locations.

Other Benefits of Fluid Condition Monitoring

The oil waste reduction aided by the TFC unit’s fluid diagnostic capabilities doesn’t just help protect your equipment. It also reduces costs and environmental impacts related to oil waste.

All hydraulic fluid must be changed eventually, but routinely testing fluid cleanliness and addressing contamination prolongs its lifespan. This results in less frequent oil disposal, saving on the expense of new oil.

Additionally, the reduction in hydraulic oil waste and consumption helps lower an operation’s carbon footprint and environmental impact. The TFC unit is part of Schroeder Industries’ Energy Sustainability Initiative supporting carbon reduction goals across various industries, thanks to the benefits it imparts by helping extend the life of oil and reduce waste.

Want to learn more about what Total Fluid Condition can do for your business? Contact us!

sisales@schroederindustries.com