Hydraulic Air Contamination Has Major Impacts

Every hydraulic system is subject to contamination from a variety of sources, including air (or gaseous) contamination. If air contamination builds up in your hydraulic system, you can expect the following:

- Gaseous cavitation. As air bubbles coalesce, grow, and collapse inside a hydraulic system, it causes loud noises and can potentially damage the internal hydraulic components.

- Spongy hydraulics. Unlike hydraulic fluid, air is compressible. As a result, too much air contamination can cause a delayed response, or ‘spongy’ feeling in a hydraulic system instead of an instant reaction. The result is inefficient, unpredictable, potentially dangerous system performance.

- Oxidation of hydraulic fluid. When oxygen reacts with hydraulic fluid, it produces varnish, a sludgy byproduct. This varnish increases fluid viscosity and can build up around valves, causing sluggish performance, damage to system components, blocked return lines and more.

Between safety issues, poor performance, and costly repairs, addressing this contamination is vital for safe and efficient hydraulic operations. Air contamination can be addressed by a specialized in-tank air filter, but not every hydraulic air filter is created equally. Enter, Air Fusion Technology by Schroeder Industries.

Air Fusion Technology: Superior Hydraulic Air Filtration

100 psi (7 bar), 40 gpm (151 l/min)

Air Fusion Technology, also known as the AFT, is Schroeder’s new in-tank air filtration solution. The AFT is engineered to increase machine reliability and efficiency, protect components, and even allow for a downsized hydraulic reservoir!

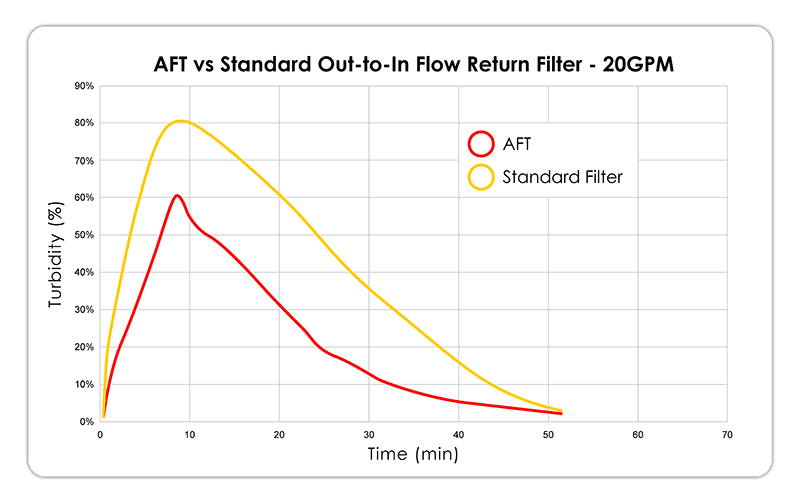

When compared to a standard out-to-in flow in-tank filter, the AFT reduced the amount of air which entered the suction line on the first pass by 20%. As the AFT decreases fluid turbidity, it channels fluid upwards and promotes rapid bubble coalescence. These bubbles quickly rise to the surface of the reservoir and dissipate.

By contrast, the traditional filter was less effective at reducing turbidity. This allowed air bubbles to stay suspended lower in the reservoir and enter the suction strainer.

What makes the AFT more effective than other hydraulic filters?

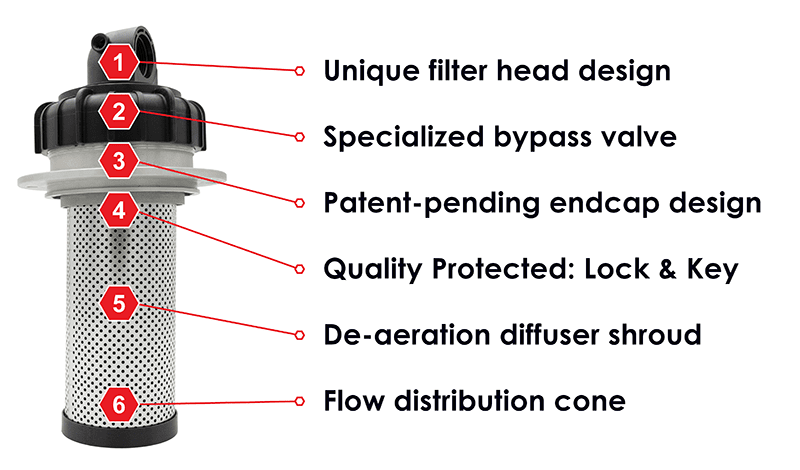

The AFT’s exceptional effectiveness is due to its thoughtfully engineered design. Let’s break down the key design aspects of this revolutionary filter:

- The unique filter head design swivels independently of the inlet port, allowing toolless element change-outs.

- A specialized bypass valve in the head of the filter allows the filter to de-aerate fluid even when in bypass for greater filtration efficiency.

- The patented endcap design allows bypass flow to enter the top of the element while still being subjected to the diffuser shroud. This helps maximize filtration.

- Schroeder’s patented Lock & Key Quality Protection element design ensures only high-quality Schroeder elements are being used. To ensure that the AFT performs at its full potential, it’s important to use only high-quality filter elements.

- The de-aeration diffuser shroud significantly reduces fluid turbidity. Less turbulent fluid allows for faster bubble coalescence and improved air filtration.

- The internal flow distribution cone redirects fluid towards the top of the reservoir, allowing air to exit the hydraulic fluid more easily.

Improve system efficiency and even downsize your reservoir!

Energy efficiency is a major component of Schroeder’s Energy Sustainability Initiative. With the AFT, our goal is to create a smaller, more efficient hydraulic system to help our customers get the most out of their fuel source, whether it’s diesel, hydrogen, or electricity.

The AFT is so effective and efficient in its filtration capabilities that it’s possible to downsize a machine’s hydraulic reservoir by up to 60%!

A smaller reservoir results in a lighter system, which can improve energy efficiency. With less room taken up by the hydraulic tank, space also becomes available for a larger fuel tank, additional batteries, or other useful components.

Air Fusion Technology will help you get the most out of your hydraulic reservoir! If you are interested in improving air filtration in your hydraulic applications, please request a quote.

1 Comment

github.com

Great job on this post! The content is exceptionally educational and well-researched, providing useful insights into the subject at hand.

The style of writing is engaging and moves smoothly, making it an enjoyable

read. I admire the effort put into communicating complex ideas

in a straightforward and concise. This write-up has undoubtedly expanded my awareness on the subject.

Well done to the writer for delivering such a top-notch work!|I’m thoroughly awed with

the high quality of this post. The writer has skillfully

presented a fair view on the subject, providing both sides of the argument in a equitable

and objective manner. The research and supporting evidence cited throughout the

article add validity to the points made. I admire the clearness of the writing, which made it

easy to comprehend and understand intricate ideas. This post is a precious resource for anyone seeking a thorough understanding of the subject matter.|This blog post is

a refreshing change! The author’s original point of view

and innovative approach make it set itself apart from the rest.

I found myself immersed in the captivating storytelling and the smooth flow of ideas.

The author’s passion for the subject shines through every word, making the

journey truly delightful. I applaud the effort put into fashioning such an distinctive piece.

Well done!|This is an remarkable article of work!

The author’s comprehensive knowledge of the topic

is apparent throughout the piece. The clear-cut and brief explanations, combined

with supporting examples, make challenging ideas effortless to

understand. I admire the thorough study that went

into this article, as it provides a strong foundation for the claims presented.

The author’s writing style is compelling and keeps the viewer hooked until the end.

I was astounded by the smooth transition between ideas and the rational structure of

the piece. The author’s ability to present sophisticated perspectives and provide

stimulating insights is admirable. It’s clear

that a tremendous amount of work and proficiency went into creating this remarkable write-up.

I warmly recommend it to anyone looking for a well-crafted and informative article.|I must say,

this article went beyond my expectations! The depth of evaluation and the distinctive perspective

provided really sets it apart. The writer’s expertise of the

subject shines through, making challenging concepts effortlessly understandable.

The writing style is gripping and grabs the reader’s attention from the very beginning.

I found myself immersed in the content, eagerly absorbing every word.

This is a praiseworthy piece of work that deserves recognition. Well done!