‘Shockingly’ Effective Anti-Static Filter Elements: Anti-Stat Premium

Leave a CommentStruggles With Static

Over the last decade, users of hydraulic systems noticed a sharp increase in unusual failures and contamination within their equipment, including:

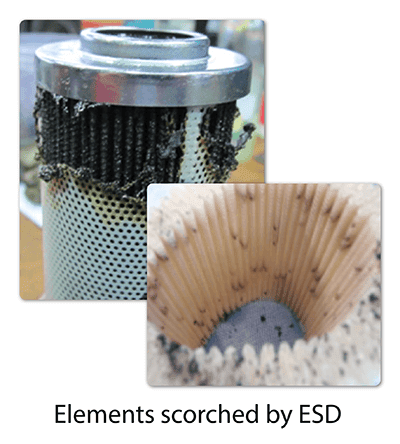

The culprit? Electrostatic discharge, also known as ESD, was becoming more frequent within hydraulic equipment. Static buildup is already a known issue, but why was it suddenly happening more often, and to greater extremes?

Behind the ‘Electrifying’ Increase in ESD

Fundamentally, static discharge in a hydraulic system is caused by friction—just like how shuffling across carpet in thick socks allows you to lightly zap someone else with static electricity. Oil may be a lubricant, but there is still some friction between hydraulic fluid and the filter media it passes through, and thus, static buildup can occur.

In a system with highly conductive hydraulic fluid or oil, this static buildup is more easily absorbed and evenly distributed. This prevents the worst effects of electrostatic discharge. However, environmental standards driving changes in oil composition meant that low conductivity oil was becoming more widespread.

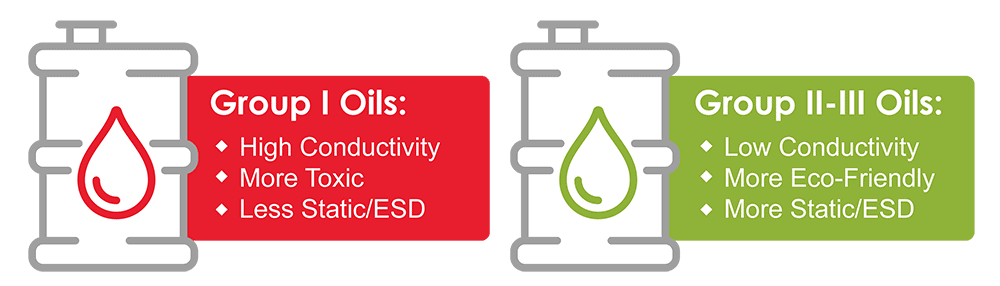

Group I ‘Lightly Refined’ Oils were once the most common class of hydraulic fluid.

Group II & III ‘Hydrocracked’ or ‘Synthetic’ oils are replacing Group I oils as a more eco-friendly alternative.

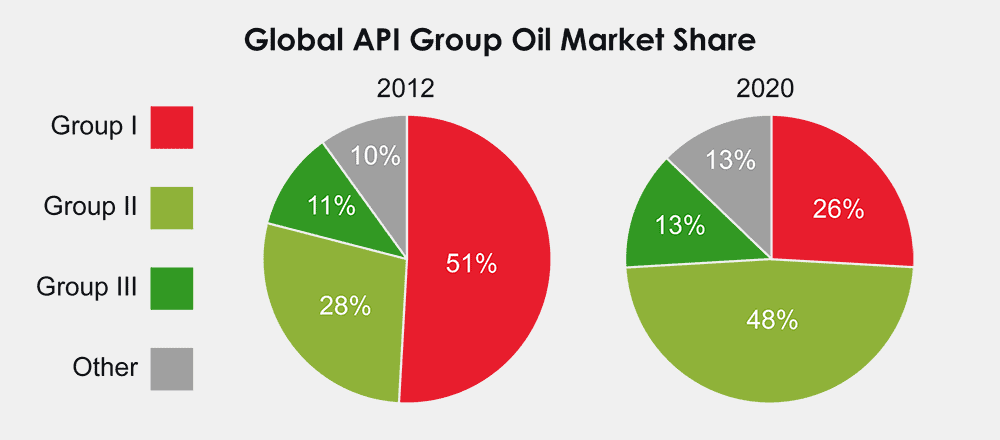

Between 2012 and 2020, the global market share of Group 1 oils fell by half, from 51% to roughly 26% of hydraulic oils in use. This trend is expected to continue. While moving away from Group I oils is much better for the environment, the proliferation of low conductivity oils led to more electrostatic discharge in hydraulic systems.

Effects of Electrostatic Discharge on Hydraulic Systems

Electrostatic discharge and static cause a variety of serious issues in hydraulic systems, including:

Anti-Static Solutions from Schroeder Industries

Anti-Stat Premium and Anti-Stat Media from Schroeder industries are engineered to combat static buildup while providing robust filtration. Because levels of ESD can vary based on factors like fluid type and temperature, two levels of protection are available.

Both offer virtually the same efficiency as Schroeder’s standard, exceptionally powerful microglass media. For superior protection from both typical particulate contamination and the effects of electrostatic discharge, look no further!

NEW: Anti-Stat Premium

Anti-Stat Media

Schroeder Anti-Stat: Proven Performance

See how these customers benefited from the static-suppressing characteristics of Anti-Stat Media!

In Need of Anti-Stat? Ask the Experts!

Contact-Blog-Anti-Stat Premium Introduction

Schroeder’s AFTF: For Superior, Stabilized In-Tank Filtration & Deaeration

Leave a Comment

Introducing the latest in Schroeder Industries’ line of powerful in-tank filters!

Using the same cutting edge technology as the Schroeder AFT, the new AFTF provides all the best qualities of Air Fusion Technology with stabilized, fixed-head porting.

Air contamination can be devastating within a hydraulic system, so having an in-tank filter that specializes in advanced deaeration can prevent substantial downtime, repairs, operational inefficiency, and more!

AFTF Benefits and Specifications

Here’s just some of what makes the AFTF one of the most powerful deaerating in-tank hydraulic filters available: