What is a Hydraulic Filter Element?

For a complete listing of Schroeder Industries‘ Filter Elements, click here.

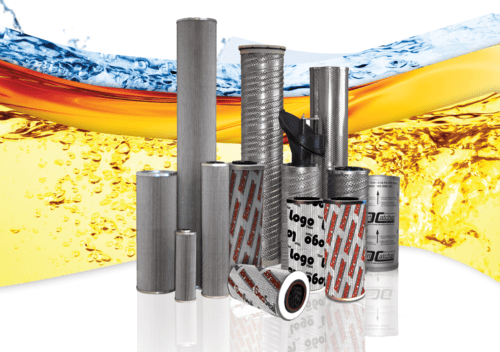

Filter elements are the heart and soul of every high pressure fluid power system. The main job of hydraulic filtration is to remove impurities and contaminants that exist in the hydraulic fluid system.

It is also used to ensure that contaminants do not interfere with the hydraulic machines’ main operating functionality (e.g. maximizing efficiency and offering low energy consumption).

When a hydraulic oil filter removes those contaminants from a hydraulic system, an increase in the fluid’s cleanliness level is achieved resulting in the reduction of machine downtime and an increase in hydraulic fluid and component life, such as hydraulic pumps, hydraulic motors, etc..

Use of Non-Schroeder Elements in Schroeder Filter Housings:

Due to the possibility of a fit, form, and function error, Schroeder Industries does not recommend nor

guarantee that a non-Schroeder filter element can be used properly in a standard Schroeder filter housing.

Other competitors and companies have a wide range of different specifications on their filter elements,

uncontrolled by Schroeder, that could alter a smooth operation in Schroeder housings and impact overall

system performance that may result in system down time.

Potential Effects of Using Non-Schroeder Elements:

- Increased and Uncontrolled ISO Counts

- Lower Beta Efficiencies

- Uncontrolled Contamination Introduced in System

- Lower Dirt Holding Capacities

- Dissimilar Component Material from Original Specifications

- Material Issues Mixing with Hydraulic Fluid

- Premature System Component Failures

- Uncontrolled System Downtime

Request a Quote – Schroeder Filter Elements

Request for Quote

How can I tell if my hydraulic filter is working?

Genuinely, a filter element’s performance can be measured. Such factors to watch include:

Genuinely, a filter element’s performance can be measured. Such factors to watch include:

- Beta Efficiency – how well it can remove contamination through fluid conditioning

- Beta Stability – how well it can maintain its efficiency throughout its life

- Dirt Holding Capacity (DHC) – how much contamination it can hold

- Lower Pressure Drop – how restricting it is on the hydraulic system

Why Schroeder Filters?

At Schroeder Industries, we have elements that:

- Remove impurities and contaminates

- Meet required cleanliness levels

- Preserve energy on system components

- Maximize overall efficiency.

Types of Filter Elements

Here are just a few examples of Schroeder Filter Media options that can help achieve those goals:

The special class of synthetic micro-glass and other fibers used in our Excellement® Z-Media® are manufactured with utmost precision and bonded with select resins to create material with extra fine passages.

No other filter media in the market is of high quality like Schroeder’s Excellement® Z-Media®.

We excel in the cartridge hydraulic filter market through the factors of:

- Maximum dirt-holding capacity

- Particle capture

- Excellent beta efficiency and stability

- Minimum pressure drop

- Low overall operating costs.

Oil filters near me

Watch on YouTube “Filter Elements” Playlist.

The use of Electric Drive (ED-Media) guarantees safe and reliable operation of your equipment while also protecting the use of excess energy.

The ED-Media series is characterized by an especially low pressure drop which makes them particularly suitable for a lower energy requirement on a system compared to conventional hydraulic power under the same ambient conditions. It saves to go green!

Series of over 2000 Schroeder BestFit® part numbers of filter cross references. The BestFit® family consists of:

- Standard cartridge hydraulic filters

- Spin-on replacements

- CoreCentric® coreless elements

- High collapse elements

- Melt-blown and spun-bonded for Process Filtration

If there is an element that cannot be crossed, Schroeder Industries can work with you in finding a replacement solution to your element problem!

For a complete listing of our hydraulic oil filters cross reference, visit our BestFit® Element Crossover Search here.

Schroeder offers Aqua-Excellement®, which excels at removing both water and solid particulates from petroleum-based fluids. The filtering media incorporated into Aqua-Excellement® includes layers of Schroeder’s high efficiency Excellement® Z-Media® for capturing particulate contaminations in combination with high water removal capabilities, making this media a winning combination.

Schroeder’s Anti-Stat® Pleat Media (ASP®) was developed to reduce or eliminate electrostatic discharging problems that can occur during filtration of hydraulic and lube fluids. By combining proven Excellement® Z-Media® and ASP® technology, it is now possible to offer both high filtration efficiency and electrical conductivity.

Watch on YouTube “ASP® AntiStat® Pleat Elements”.

The CoreCentric® Coreless series are environmentally friendly, all plastic elements (no metal parts) that can be crushed, shredded, or burned. These alternative methods of disposal will not only greatly reduce solid waste volumes, but also reduce disposal costs simultaneously. Built with Excellement® Z-Media®, the CoreCentric® Coreless series is designed to ensure optimum performance and ease of service.

Far too often, customers make purchasing decisions based solely on price, only to be extremely disappointed with the poor quality delivered by low cost imitations. To make the matter worse, the customer often points an accusing finger at the filter housing manufacturer for poor performance, rather than the inadequate element they used as a replacement for the original Schroeder element. That is where Quality Protection is the answer, and Schroeder Industries offers different Quality Protected designs for your need:

DirtCatcher® offers a superior alternative to inside-out filtration. The patented outer shell prevents contaminants from falling back into the system during element changes while still providing the excellent dirt retention of Excellement® media. The DirtCatcher® solution provides peace of mind to those concerned with dirt escaping from elements during the removal process while delivering all the advantages of Schroeder original (outside-in flow) elements.

GeoSeal® is a patented offering that provides a unique way for OEM’s to retain replacement element business and keep a filter’s performance at the quality level that it was originally supplied. The idea is brilliantly simple: the critical sealing arrangement between a filter housing and its replacement element takes on a shape other than the standard circular arrangement. Specifically, the element grommet & mating bushing are given a new geometric shape.

With numerous micron ratings and media options, there is a solution for you!