Why Superior Oil Analysis is Your Key to Success

Leave a Comment

Clean Oil is the Key to Productivity

Is your hydraulic equipment experiencing more downtime than usual? Are you noticing that your equipment is operating less efficiently?

If your operation is paying a price for the inconsistent performance of your vital equipment, high contamination is most likely to blame.

Hydraulic fluid contamination from a variety of sources is by far the most common cause of system inefficiency and failures. In fact, approximately 80% of all hydraulic equipment failures can be directly attributed to the effects of fluid contamination!

Consistently clean hydraulic oil is vital to every operation that relies on hydraulic equipment. Additionally, systems that rely on process water or run on diesel fuel are also vulnerable to the effects of contamination. Proactive measures to analyze fluid and prevent contamination provide significant benefits to cost and productivity:

Struggling with Fluid Contamination? Fluid and Oil Analysis Services by Schroeder Industries Can Help!

Backed by over 75 years of innovation, Schroeder Industries is a leader in developing filtration products and technology that detect, analyze and remediate contamination to protect hydraulic systems and other vital equipment.

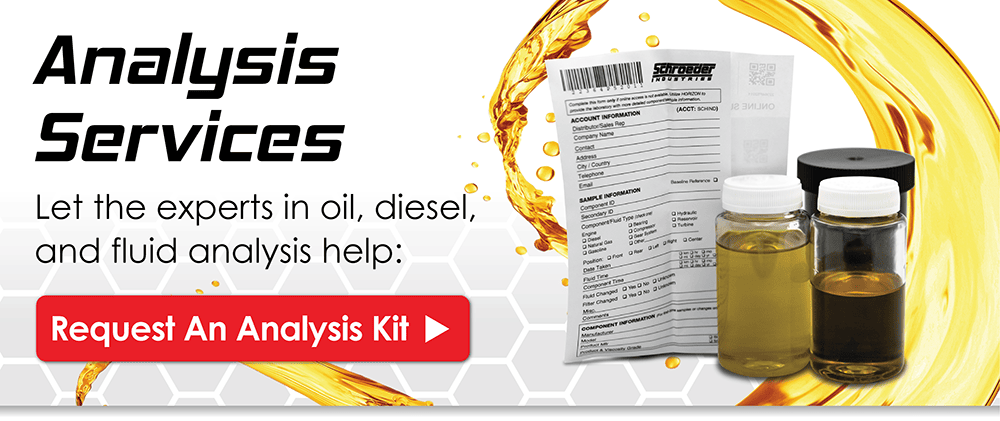

When contamination is attacking your equipment, the first step towards an effective filtration plan is a thorough analysis of the affected fluid, be it oil, fuel, or water.

Our fluid health experts will test your samples and create a detailed report, identifying the type and potential sources of contamination in your system and giving recommendations on how to best protect your equipment.

Schroeder offers a variety of premium testing kits, including:

Monitor Contamination with Schroeder’s State-of-the-Art Fluid Care Portal

Regular testing is vital for monitoring trends in your fluid health and preventing problems before they arise. However, tracking results over time for many pieces of equipment takes time and hassle.

As part of our testing and analysis services, Schroeder Industries is now offering a smart digital solution for detecting trends in the quality of your hydraulic oil, diesel fuel, process water, and more.

The Fluid Care Portal is a new, powerful digital tool for easily tracking the health of your equipment’s fluid as you test over time:

Schroeder Filtration Services

Once a proper diesel, fluid or oil analysis has unlocked the source and quantity of contamination, filtration is the next step.

If you aren’t prepared for the upfront cost of purchasing filtration equipment, Schroeder Industries makes our state-of-the-art equipment available through our Rental Program and Filtration Management as a Service. Learn more about how these services can benefit your operation!

Schroeder Rental Equipment Program

Enjoy the benefits of Schroeder Industries’ exceptional filtration equipment without a large capital investment. Superior filtration extends oil life and increases machine reliability and energy efficiency.

Filtration Management as a Service (FMaaS)

With this turnkey service, Schroeder Industries will plan, execute, and manage your filtration strategy and filtration equipment, allowing you to focus on running your business with peace of mind!

Take the First Step in your New Filtration Plan

Our fluid care experts can help you determine the right test kit for your needs and provide vital insight into the health of your fuel, process water, or hydraulic oil. Contact us today!