What is Filtration Management as a Service (FMaaS)?

Implementing a filtration plan can be challenging and costly. Outsourcing your fluid cleanliness needs to Schroeder Industries’ filtration experts makes it simpler and more affordable.

With FMaaS, Schroeder owns, delivers, and maintains the filtration equipment needed to achieve your oil cleanliness goals:

- We work with your team to analyze your fluid health and establish your fluid conditioning goals.

- We deploy our industry standard equipment to constantly filter and/or dehydrate the hydraulic & lubricating oils in your plant to meet these goals.

- We also offer the ability to track proportional condition changes with remote monitoring capabilities independently from your distributed computer system (DCS).

- We manage the fluid cleanliness process to ensure machine uptime and to all but eliminate the need for contracting with a mobile recycling company.

- Filtration Management as a Service is performed at a very competitive cost per gallon versus similar services.

How Does On-Site FMaaS Help?

Did you know that more than 70% of all machine failures can be traced back to contaminated hydraulic oil?

Particulate contamination is extremely damaging to hydraulic equipment, ranging from visible dirt to ‘invisible’ particles only a few microns in size. Constant abrasion from solid particles wears out bearings and seals, damages pumps, and causes valves to stick. Water and gases can also contaminate the hydraulic system via worn seals or by entering the reservoir.

Damage from uncontrolled contamination can lead to costly repairs and lost productivity. Although contamination cannot be completely stopped, it can be controlled through proper filtration. However, developing and executing a filtration plan can be challenging:

- The equipment required to diagnose and monitor fluid health can be expensive. But, without accurate real-time data, attempts at filtration are only a shot in the dark.

- Filtration equipment also requires considerable investment.

- Operating and installing analysis and filtration equipment requires training and expertise. Hiring or training dedicated filtration personnel is yet another expense.

- Companies may not have the manpower to run their systems at OEM-specified cleanliness levels.

Not every company has the capital or manpower to invest in and manage their own filtration strategy, which is where Schroeder’s Filtration Management as a Service comes in.

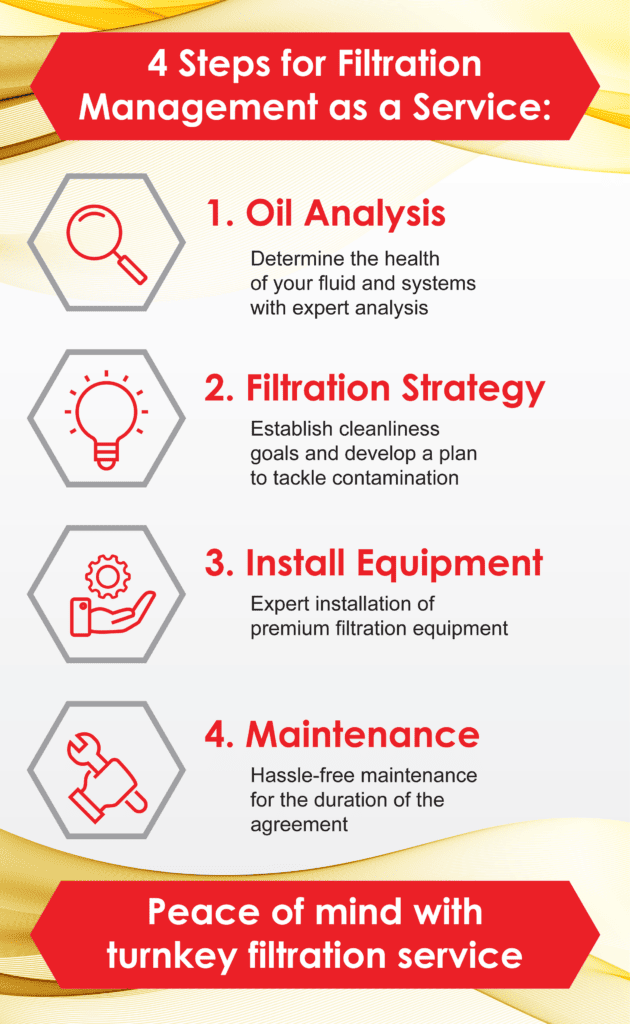

How Does FMaaS Work?

With FMaaS, filtration experts from Schroeder Industries will plan, execute, and manage your filtration strategy and filtration equipment. When you participate in FMaaS, protecting your hydraulic systems from contamination becomes one less hassle on your plate.

Step 1: Oil Analysis

Any successful oil filtration program requires accurate diagnostics. An oil analysis will help to determine the health of your system. With the source, type, and quantity of contamination established, a filtration strategy can be developed.

Step 2: Filtration Strategy

Once the oil analysis is complete, Schroeder’s filtration experts will collaborate with your team to develop a customized filtration strategy to meet your operation’s needs.

Step 3: Install Equipment

Schroeder Industries offers a full range of filtration products and accessories, backed by decades of innovation and proven performance. Our filtration equipment extracts particulate and/or water contaminants present in hydraulic systems safely and efficiently.

Schroeder’s experts will oversee the installation of the required filtration and/or dehydration equipment in the customer’s plant.

Step 4: Maintenance

Schroeder Industries will maintain the equipment for the duration of the FMaaS agreement. During this turn-key service period, there is a fee per gallon of oil processed.

Our kidney loop filtration units allow us to connect directly to the hydraulic or lube oil reservoir(s) and filter the system while it continues to operate. With high flow rates to turn over the reservoir volume and high dirt holding capacity (DHC) elements, particulate contamination is easily removed, and system cleanliness can be maintained.

Our dehydration units are installed and directly connected the lube oil reservoir while the system is in operation to remove both free and dissolved/emulsified water. Particulate filtration is also included on the dehydrator to filter the fluid before it is returned to the reservoir.

Why choose a fixed installation oil recycling/conditioning program for your critical assets vs. an on-demand mobile truck oil recycling contract?

- Schroeder doesn’t just fix your oil or offer a one-size-fits-all solution: we tailor a plan specifically for your operation.

- The Schroeder FMaaS system is less disruptive than scheduling oil recycling visits

- In house filtration with FMaaS helps reduce your operation’s carbon footprint by eliminating repetitive oil recycling truck visits and the associated emissions.

- Oil waste is reduced and, in the case of some oil types, potentially eliminated.

- Our service comes without the overinflated scope or budget creep that day rates can bring, at a competitive cost per gallon.

- As an example: If you recycled 10,000 gallons at a $1.00 per gallon, we can maintain the same reservoir for 30% less per gallon and extend the life of that fluid with a continuous fluid cleanliness process. We are unique because our process is continuous (i.e. we continuously maintain and monitor the fluid quality). We don’t fix a problem, we stop it from occurring. We’ll run our fixed systems for a month at a charge that is 30% less than what the oil recycler charges for a one (1) time clean up.

What FMaaS means for your business:

FMaaS provides superior, cost-effective on-site filtration solutions in one convenient package with numerous benefits:

Get a FREE Filtration Management as a Service Estimate!

Schroeder Filtration Management as a Service (FMaaS)

All interested entries for Schroeder’s all-new Filtration Management as a Service (FMaaS) program.