Rising oil and fuel costs, trends towards electrification, and overall concerns about sustainability across virtually every industry are driving an increased push for improved efficiency in the designs of hydraulic equipment.

One area where great opportunities for improvement lie is with the hydraulic tank. Due to inefficient designs, many machines operate with oversized hydraulic tanks containing more oil than needed.

Many benefits can be realized through tank optimization, including:

- Increased energy efficiency

- Overall machine weight savings

- Steel and oil savings per machine

- CO2 emission reduction

- Tank downsizing

- Additional machine space for other features

Read on to learn more about the benefits of optimizing your hydraulic reservoir, and how Schroeder Industries can help:

What Is Tank Optimization?

The goal of hydraulic tank optimization is to reduce the reservoir size and thus reduce its fluid volume. Two main factors determine how much a tank can be optimized:

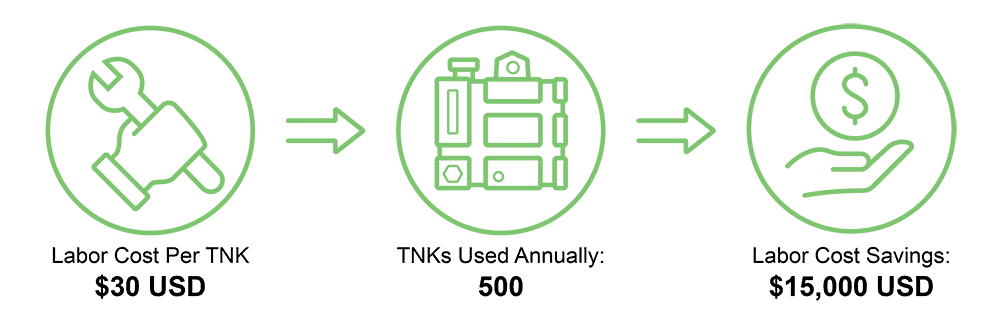

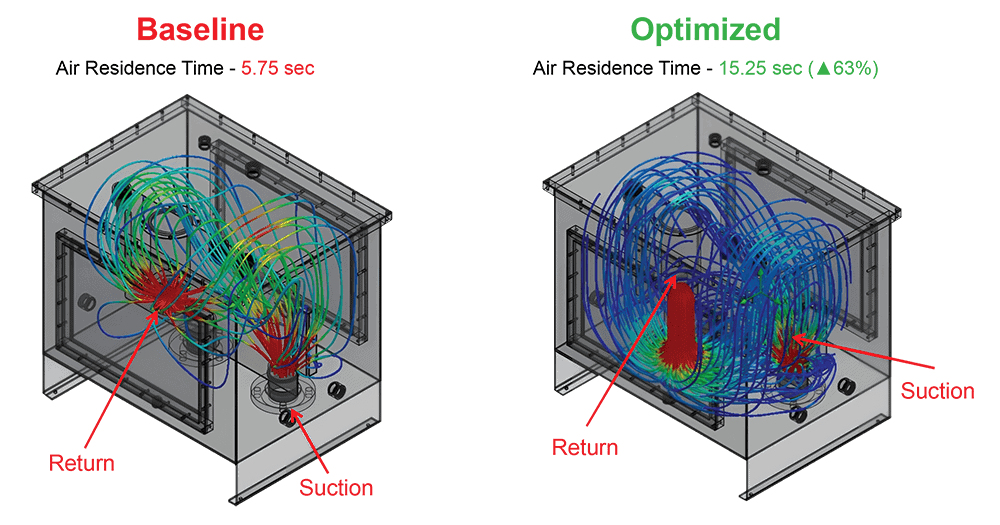

- Volume Utilization. In a suboptimal reservoir design, ‘dead zones’ can appear, where fluid stagnates and is not effectively utilized by the system. In a properly designed tank, every cubic inch of the hydraulic fluid should circulate within the reservoir. Dead zones can be detected by digital simulations, and are a strong indicator that tank optimization is needed.

- Fluid Velocity. Fluid velocity impacts how well a tank can de-aerate, or release trapped air from within the fluid, and prevent new air from entering the fluid due to splashing. Increased air contamination causes a variety of issues within hydraulic systems, decreasing operating efficiency and component lifespan. Fluid velocity can be reduced through improved in-tank filtration and adjusting the structure of the hydraulic tank itself.

The Benefits of Hydraulic Tank Optimization

Here’s some of the ways optimizing a hydraulic tank design can benefit both OEMs and end users:

The benefits of optimizing your tanks are clear, and the filtration experts at Schroeder Industries can help you get the most out of your reservoir.

Tank Optimization Services from Schroeder Industries

Schroeder Industries is leveraging our extensive experience in hydraulic system filtration components towards tank optimization. Through cutting-edge flow simulations, our experts can identify dead zones and inefficiencies in hydraulic tank designs and work with your company to develop a solution that suits your specific application.

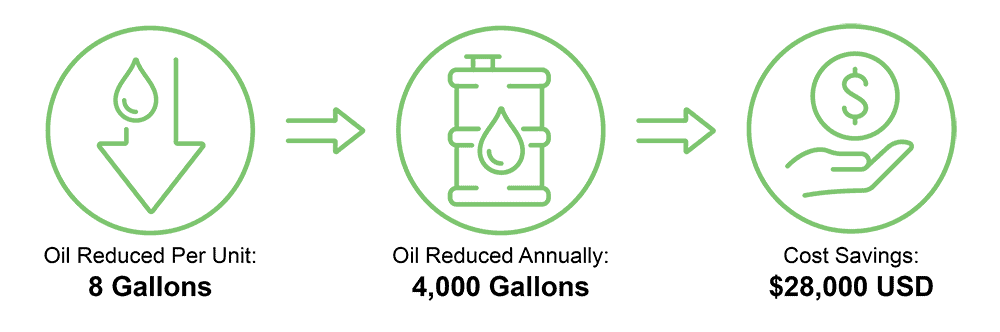

The benefits of optimizing your hydraulic tank are more than just theory. In the following case study, learn how one OEM saw substantial savings with Schroeder’s tank optimization services:

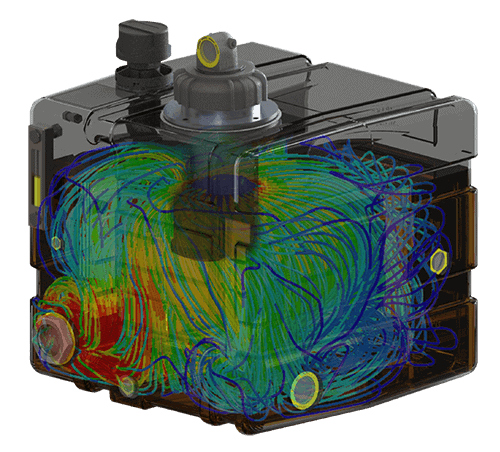

TNK Series and Air Fusion Technology

Schroeder’s tank optimization services are backed by expertly crafted reservoirs and filters. Learn more about these premium products:

Ask The Experts How Your Tank Can Be Optimized!

If you could be getting more out of your reservoir and in-tank filtration, Schroeder Industries can help.