Contamination in hydraulic fluid – a myth or reality?

How often have you been told from an asset manager,

“My oil is clean?” Or how about,

“I don’t see any contamination in my oil,” as a bottle of hydraulic oil is held up to light?

You might have even heard other common adages, such as:

“The oil supplier wouldn’t send me dirty oil.”

“I have a filter on the tank to catch the contamination,” later finding out that the filter element has clogged and the filter in bypass, or that the filter element was missing altogether!

“My reservoir is sealed. How did water get in there?”

And the list goes on and on…

Contamination control is an important part of operating and maintaining hydraulic systems.

It starts with the identification and measurement systems of the different forms of contamination. Once a company has identified the contaminants and source of the contaminate, they can develop a strategy for an efficient, real-world method of controlling and maintaining acceptable contamination levels in a hydraulic system.

The result will be improved fluid condition and consequently extend life expectancy of fluid and equipment resulting in significant cost savings.

Types of Contamination

Various types of contamination occur in fluid power systems: solid contaminants, liquid (e.g. water), gaseous (e.g. air) and gel-like contaminants.

Another often-overlooked source for premature fluid degradation and consequent system damage is heat. This is especially important if the tanks size is small and the fluid does not have enough time to properly cool down.

Contamination can cause substantial damage in fluid power systems if they are not removed as quickly as possible. Preventive measures should be taken to reduce the ingress of contaminants in systems.

The contamination that can be most detrimental to a system in operation is one not visible to the naked eye. To put it into perspective, an average healthy human eye can see items down to approximately 40μm (Microns) in size. In comparison, a human hair is 70 to 80μm in size.

Particles that cause problems in high performing, high pressure hydraulic systems are in the range of approximately 5 to 15μm. 1μm is equal to 0.001 mm or 0.000039 Inches.

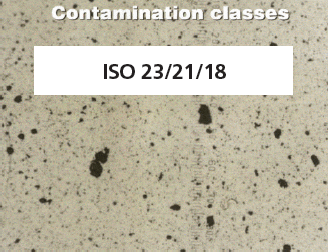

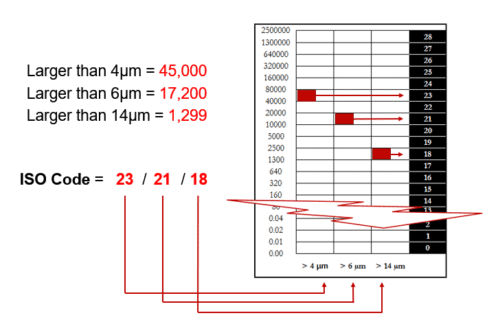

Particulate contamination in a system is often reports as an ISO (International Organization for Standardization) Code. The objective of the ISO Standards 4406:1999 is to classify quantity of particle contaminants in hydraulic fluids by particle size. Particle counts are determined cumulatively, i.e. > 4 μm, > 6 μm and > 14 μm, and coded for easy comparison. The following table explains how the ISO code is determined for a particular fluid sample:

Sources of Contamination

The source for particulate contamination is often found to be the hydraulic reservoir.

Often the reservoir is filled with fluid without first being cleaned. Dirt can be added during maintenance cycles, the tank is open to the environment and missing or has low quality air breathers installed on the tank.

New fluid coming into the plant (in a drum, tote or truck) is generally dirtier than what a system, and specific components in the system, would require for proper performance and/or adequate life expectancy. Over time, pipe scale/rust, pump wear and dirt on rods/cylinders can add contamination to the fluid.

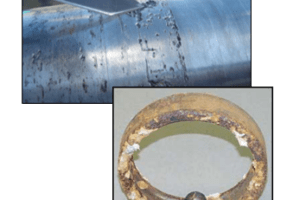

Particulate contaminants circulating in fluid power systems cause surface degradation through general mechanical wear (abrasion, erosion, and surface fatigue). This wear causes increasing numbers of particles to be formed, the result being that wear increases if the “chain reaction of wear” is not properly contained (by reducing contamination). Gaps grow larger, leakage oil flows increase in size and operating efficiency (e.g. of pumps, cylinders) decreases.

Water contamination in the hydraulic systems can be caused by moisture from ambient air, leakage of cooling systems or process water, leakage of seals and chemical processes such as combustion, oxidation and neutralization. As more water enters the fluid, the fluid will develop a haze to milky/stratified appearance when fully saturated.

Dissolved Water is responsible for:

- Faster oil oxidation: Accelerates this form of oil degradation, leads to oil acidity, thickening, varnishes, sludge & resins

- Reduced Fatigue life: Propagation of fatigue cracks in metals

- Demolition of Ester-based fluids and additives: Reacting with esters – hydrolysis, results in formation of acids, gels, and loss of additives

Free Water causes:

- Corrosion: Corrosion pits, rough surfaces and release of abrasive flakes into the fluid

- Microbial colonization / Bacteria: Odors, acids, slime, and health problems

- Loss of lubricity: High friction, wear and seizure of components due to additive reduction/depletion seen with high water content

- Additive depletion: Free water retains polar additives

Design issues in the hydraulic system can contribute to air/gases in hydraulic fluids. If the return line is above the fluid level in the tank, air can be mixed into the fluid. Incorrect motor speeds, unprimed pumps, suction lines too small, suction lifts too high and blocked inlets are among other reasons for air contamination over time.

Air effects:

- Oil oxidation: Mostly oxygen reacts with oil resulting in premature degradation (oil aging)

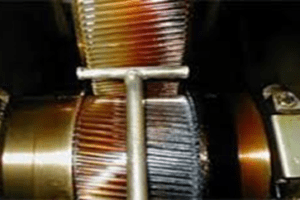

- Varnish formation – lacquer like deposits as shown in photo (oil aging)

- Cavitation: Formation and collapse of gaseous oil cavities causes decrease in pump efficiency and damage to pumps

- Micro-Diesel-Effect – Air bubble implosion generating high heat which “burns” the oil surrounding the air bubble

- Change of viscosity

Hydraulic component clearances are critical and require strategic filtration designs to remove damaging particles. In hydraulic systems, 70 to 90% of wear and failure is contamination related. Only 10 to 30% can be traced back to misuse, defects or age. Contamination cannot be stopped, only slowed down!

System efficiency can drop by up to 20% before an operator even detects a problem, such as cylinder drift, jerky steering, erratic operation or slower performance. Overall, contamination results in shorter service intervals, higher operating costs and lost productivity.

5 Comments

Sergio Martinez

Excelente articulo, felicidades…

hydraulic

There are few maintenance people with the experience and training in The electro-hydraulic pump is only one component in a larger system

hydraulic

In most cases, we would recommend a service every 12 months as a starting point. If oil remains clean and components in good repair across several services, i

hydraulic

We offer comprehensive hydraulic repair and remanufacturing services for marine and fishing applications. We are also an authorized distributor of Bosch

hydraulic

We also offer insightful troubleshooting and repair of marine hydraulic systems and components, including pumps, motors, valves, cylinders, fittings, and hose