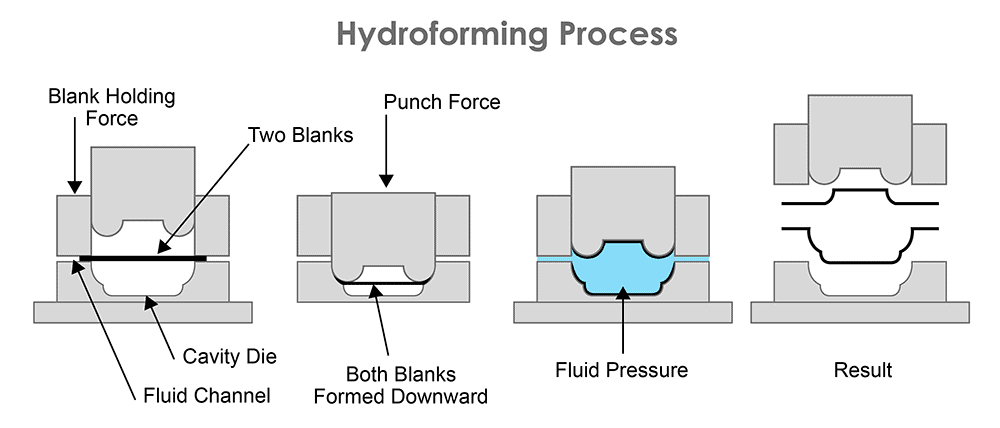

What is hydroforming?

Hydroforming is a specialized deep draw manufacturing process used to create a wide variety of metal components and is especially popular within the automotive industry.

In the sheet hydroforming process, highly pressurized water is applied into a mold, and the water pressure forces the metal to conform to the shape of the die.

Compared to conventional stamping methods, hydroformed parts can be created in more complex shapes with greater efficiency, thinner metal sheets, and high-quality surface finish.

Why is process filtration so important for hydroforming applications?

Like any process water application, contamination can greatly affect the lifespan and performance of the high-pressure hydroforming press.

To protect vital downstream components like high pressure pumps and manifolds from wear and tear, high-quality process filtration is a must for any hydroforming system. If left unchecked, contamination can wear out machine components, reducing operational efficiency and forcing expensive repairs and costly downtime. Additionally, defective/scrap material output can increase.

The process filtration experts at Schroeder Industries understand the impact that high-quality filtration has on a business. We can find a Schroeder solution for virtually any process filtration application, including hydroforming:

Why is an AutoFilt® RF9 from Schroeder Industries the best choice for your hydroforming application?

The AutoFilt® RF9 is Schroeder’s first choice for filtration in hydroforming applications. Already, the RF9 has seen great repeat success in the hydroforming division at one of the world’s largest automotive frame manufacturing plants.

Here’s what makes the RF9 so effective:

Let the experts at Schroeder Industries help find the perfect solution for your process application!

Backed by over 75 years of innovation, industry experience, and proven successes, Schroeder Industries can work with you to find the optimal solution for your filtration needs. Let us know how we can help you: