What is component cleanliness testing?

Component cleanliness testing offers OEMs the ability to see the cleanliness of the components they are using to build a system. For vendors, it allows them to measure the cleanliness of a component that they manufacture and sell to an equipment manufacturer.

Why is component cleanliness testing important?

Roll off cleanliness for OEMs is increasingly vital as they strive to put out quality product from the assembly line. It’s not enough anymore to simply provide a machine with clean fluid: The cleanliness of the components used to build the machine is playing a large role in overall system performance!

Even suppliers with good cleanliness practices may end up with particulate contamination as items are shipped, handled, and stored. Any amount of contamination on the hydraulic system parts can affect machine performance—even for brand-new machines.

Cleanliness provides the following benefits:

Interested in component cleanliness testing, but unsure where to begin? Our cleanliness experts can help!

How can I measure component cleanliness?

Schroeder Industries, an expert in contamination control, offers several solutions for monitoring and maintaining component cleanliness.

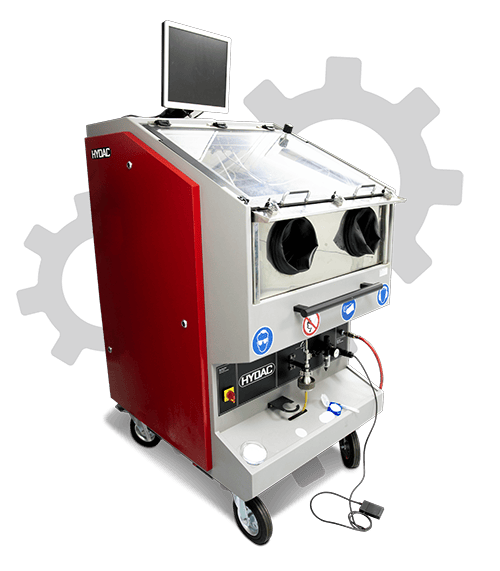

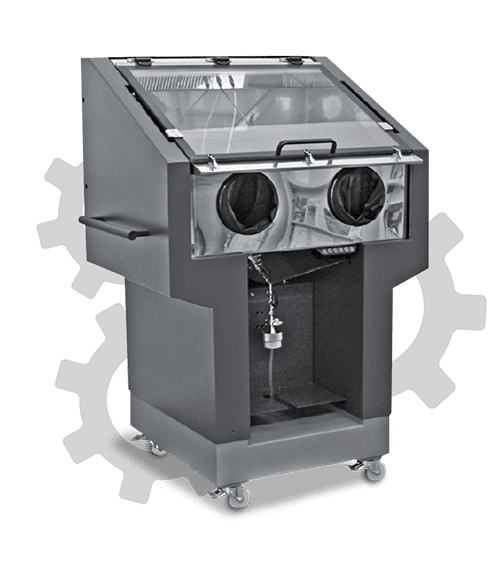

Our CTU and CTM Modular Series of Component Cleanliness Testing Cabinets were designed to determine the technical cleanliness especially present on minor contaminated components. These Test Cabinets were developed due to increased demand for system cleanliness and for monitoring and optimizing the cleanliness of smaller components during production, storage and system assembly.

By determining the type, size and quantity of the contamination, quality standards can be checked and documented and the necessary steps towards optimization can be taken.

Benefits to You:

Learn more about our Component Cleanliness Testing Cabinets:

Budget limitations? We offer cleanliness testing services!

If a Test Cabinet unit is outside of your budget, Schroeder Industries offers testing services in our on-site Fluid Care Center.

In a clean environment, our technicians will conduct expert testing on your machine components, establishing the foundation for your cleanliness plan.

Benefits of this Turnkey Service:

Schroeder Industries can help with your component cleanliness testing needs!

If you would like to have us quote Component Cleanliness Testing of your parts, please contact us using the form below. We will review the components to be tested and method to determine the desired gravimetric or ISO code required.