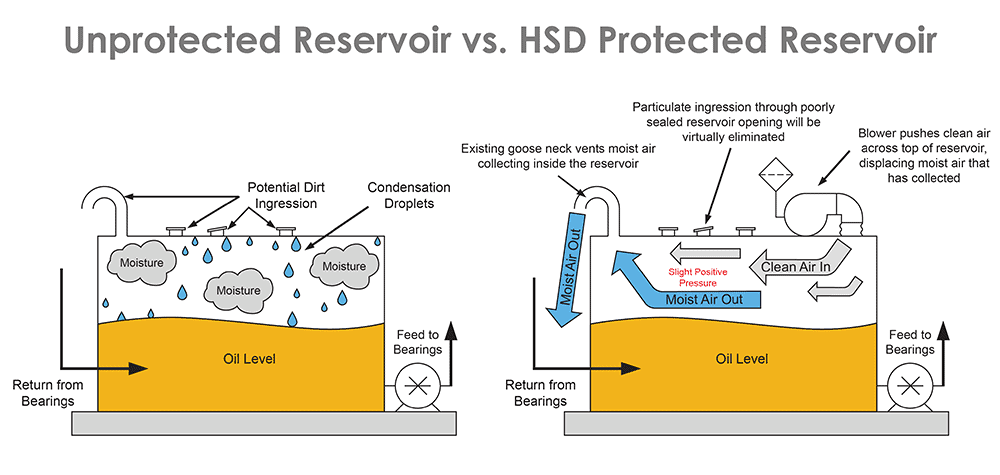

Most hydraulic reservoirs in major industries including pulp & paper, primary metals, and more feature a pocket of open space between the fluid level and the top of the reservoir. This open space, known as head space, fills with moisture as humid air ingresses via faulty seals, vents, and other entry points.

As the moisture builds in the head space, water condenses at the top of the reservoir, eventually coalescing and falling into the oil.

This water contamination can cause a range of serious problems which can impact your equipment’s efficiency and may require repairs, including:

- Rust

- Cavitation

- Sensor failures

- Reduced oil lubricity

How Schroeder’s Head Space Dehydrator Helps:

Dewatering units such as the Triton Dehydration Stations are excellent for targeting water contamination when oil has already become saturated, but preventing contamination before it reaches critical levels is ideal.

The new Head Space Dehydrator is designed to combat moisture in the head space of a hydraulic reservoir before it contaminates the oil. This unit is permanently installed on a hydraulic reservoir so that humidity inside the reservoir can be managed continuously.

Here’s how it works:

- The Head Space Dehydrator assembly pulls ambient air into the chamber through a series of particulate breathers.

- The clean, dry air is then blown through the head space above the fluid level, displacing and venting the moist internal air though existing ventilation points.

- As the moist air is displaced, the opportunity for water contamination via condensation is reduced.