Spin-on filters are very commonplace in the world of hydraulic filtration. Unlike cartridge filters, spin-ons combine the filter media, housing, base plate, and gasket into one disposable unit.

While they are known for their convenience, the disposable design of these filters comes with drawbacks. Does the ease of use really outweigh the downsides?

Let’s review the pros and cons of spin-ons!

Spin-On Filters: The Benefits

It’s not for nothing that spin-on filters are popular in hydraulic applications:

Spin-On Filters: The Drawbacks

But, while convenience is a helpful quality of spin-ons, their disposable nature has some significant downsides:

Counting the Cost of Spin-Ons

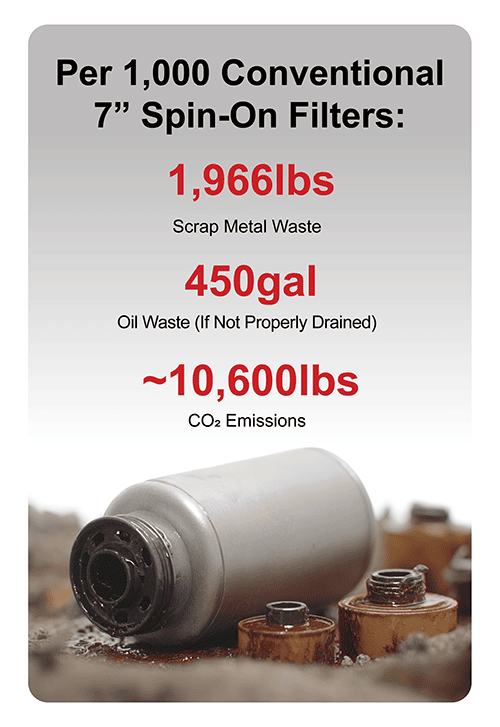

The greatest downside of spin-on filters is the sheer amount of material and oil waste involved. Let’s look at an example of how much waste is produced by a very common spin-on type:

Waste Reduction example, per 1,000 spin ons:

7″ M10 (cellulose 10 micron) Spin On

Millions of spin-on filters are discarded every year, contributing to a staggering amount of unnecessary waste!

Is It Time For A Change?

While spin-on filters are a convenient and effective choice for filtration, the wasteful nature of conventional spin-on technology can’t be ignored.

Between environmental repercussions and potential missed revenue, spin-on filtration technology is long overdue for an upgrade.

Material and oil costs rise with each passing year. With the amount of metal and oil wasted with each spin-on, it’s likely that users could be paying more than they need to for their spin-on filtration.

Could a less wasteful, more cost-effective spin-on alternative not only reduce emissions, but save money for hydraulic-driven operations?

Can the convenience and user-friendliness of spin-ons be combined with the economical, lower-waste benefits of cartridge filters?

Schroeder Industries thinks so.

Coming Soon: A Sustainable Revolution in Spin-On Technology.

A low-waste, cost-effective, high-performance spin-on alternative is coming soon. Stay tuned for Schroeder Industries’ most game-changing innovation yet!

Get Notified of the Launch!

Register for our mailing list to receive an email notification when this revolutionary spin-on filter alternative formally launches: