In hydraulic systems, up to 70% to 90% of wear and failure is contamination related.

Monitoring hydraulic fluid for contaminants is the best way to predict and prevent unexpected failures and avoid costly repairs.

Building out an arsenal of contamination sensors is critical for asset protection. Solid contamination sensors, or particle counters, are one of the pillars of every successful contamination control plan.

Solid Contamination Monitoring

Solid contamination is the most common form of contamination. Ambient dust and dirt within the plant, machining debris let over in newly installed components, and even newly added hydraulic oil are just a few of the ways solid particles can enter a system.

With so many solid contamination sensors on the market, how do you know which is right for your application?

Solid Contamination Sensors

There are a few basic characteristics that distinguish particle counters, from each other:

Light-Based vs. Digital Imaging Sensors

Particle counters rely on either light-based or digital imaging technology to detect and measure particles. Each type has its own benefits and drawbacks:

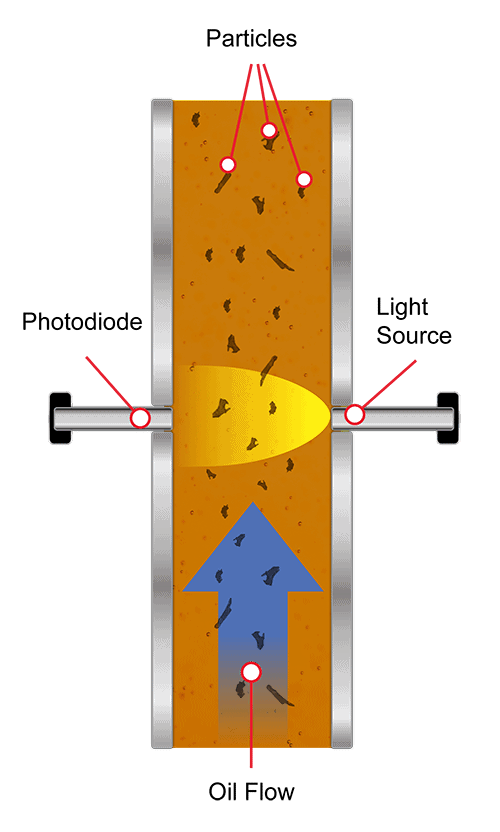

Light-Based Sensors

This type of sensor includes a light source that shines on the fluid as it flows past. On the opposite side of the light source is a light sensor (also called a photodiode) which detects the shadows cast by passing particles. Based on the size and quantity of the shadows being cast, the sensor determines the size and quantity of contamination in the fluid.

Digital Imaging Sensors

These sensors avoid phantom particle counting by using image recognition software. Unlike solid contamination, air bubbles and water droplets are very uniformly round. The software can automatically disregard these perfectly round bubbles and drops from its particle count.

In-Line vs. Portable Sensors

Particle counters may be dedicated to a single piece of equipment, or available in a travel-ready unit:

In-Line Sensors:

These sensors are installed directly onto pieces of equipment and monitor that specific machine. They can be easily customized and combined with other types of sensors and accessories.

For plants with fewer, larger machines, a dedicated in-line sensor is a great way to monitor individual machines as they operate!

Portable Sensors:

Portable particle counters are stand-alone units which include their own built-in pump, allowing them to travel between machines.

A portable contamination monitor can travel wherever fluid condition monitoring is needed and easily perform checkups on multiple machines and vehicle fleets!

Reporting and Connectivity

The best data in the world isn’t much use if it can’t be exported, compiled, and reviewed! This is where IoT, the ‘Internet of Things,’ becomes important for making use of the information gained through the sensors.

Contamination monitors typically have some method of transferring data, be it through Bluetooth wireless connectivity, thumb drives, spreadsheet files, SCADA/PLC interfacing, and more.

Integration with user-friendly, web-based applications that can compile, track, and visualize data from multiple sensors is becoming increasingly common as well!

For large-scale operations, using automated data transfer and logging methods that can process high volumes of data and quickly determine trends in the level of contamination are crucial for efficiency.

Solutions from Schroeder Industries

Here are just a few of our featured particle counters and contamination monitoring solutions!

CS1500 Series

The latest evolution in Schroder Industries’ contamination monitoring arsenal, featuring enhanced connectivity!

Total Fluid Condition (TFC)

A robust, portable contamination monitoring unit that travels wherever you need highly accurate ISO readings!

Sensor Calibration Service

Contamination sensors should be calibrated approximately every two years to ensure accuracy.

The fluid care experts at Schroeder Industries can calibrate your sensors and keep your systems protected!

Condition Monitoring Starter Kits

Getting started with contamination sensors can be challenging, but Schroeder’s Condition Monitoring Starter Kits make it easy!

These starter kits have been curated by our experts for a variety of applications and scenarios.