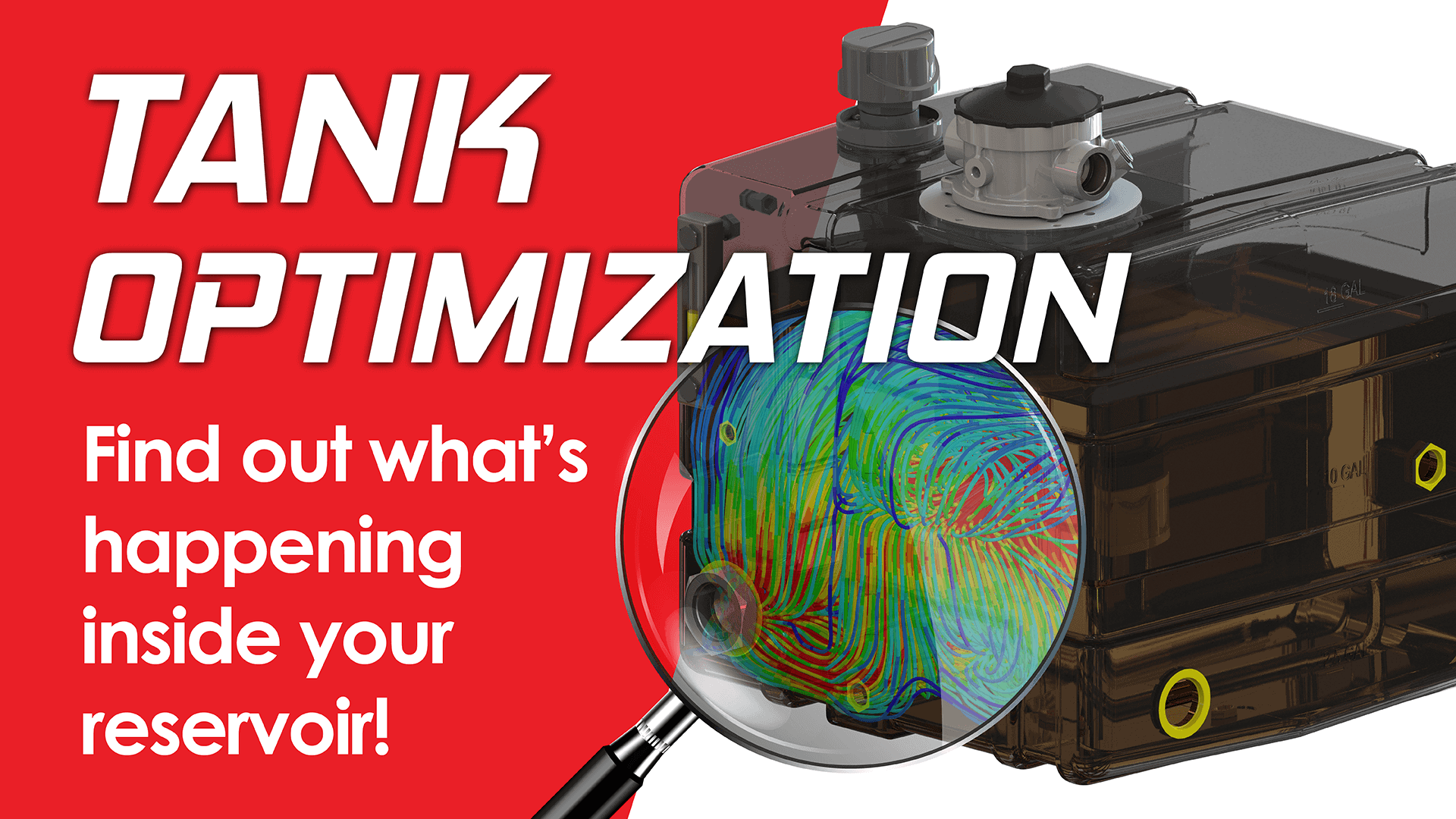

Do You Know What’s Happening In Your Hydraulic Tank?

It may surprise you to hear that many hydraulic reservoirs are oversized and inefficient!

Tank Optimization can give you important insights into how fluid moves inside your reservoir, and put you on the path towards a more efficient, cost effective, sustainable machine.

What Is Tank Optimization?

Tank Optimization aims to reduce reservoir size and improve performance by addressing the following:

What Can Tank Optimization Do For You?

The ultimate end goal of Tank Optimization is to improve system efficiency, and a reduction in tank size and fluid volume can have a range of benefits for the design, energy consumption, cost, and carbon footprint:

Increased Machine Space

A smaller hydraulic reservoir creates opportunities for design improvements. Tank Optimization can enable a larger fuel tank or battery, additional supply storage, or even an overall downsizing of the machine!

Improved Energy Efficiency

Reducing the tank size/overall fluid volume reduces both the weight and warmup time of the hydraulic system, allowing the equipment to operate with lower energy consumption.

Conservation of Resources

A smaller hydraulic tank means less oil is needed on the first fill for OEMs and on all subsequent fills for the end user, saving on oil-related costs! Additionally, the tank assembly will require less material to manufacture.

Increased Sustainability

Improving fuel efficiency, reducing oil volume, and minimizing the material needed to construct the system’s reservoir through Tank Optimization all contribute to a reduced carbon footprint.

How Does Tank Optimization Work?

Through cutting-edge simulations and CFD analyses, Schroeder Industries provides our customers with real world data on various tank dynamics and characteristics to uncover inefficiencies in the tank assembly and develop optimized solutions for virtually any application.

Schroeder’s experts assess a range of characteristics in the tank analysis process:

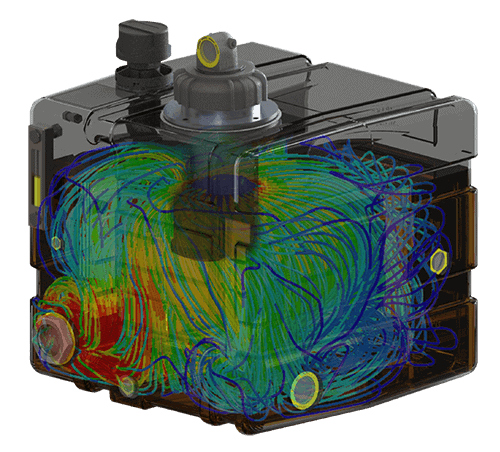

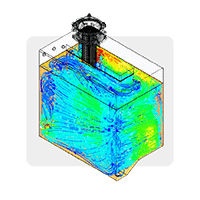

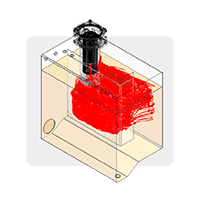

Flow Simulations

One of the most important tank characteristics is flow. Flow simulations assess the flow patterns and velocity of fluid in the tank. Is the flow fast and turbulent? Are there stagnant pockets (dead zones) in the reservoir?

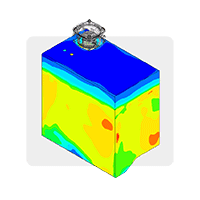

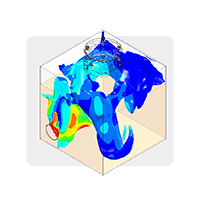

Thermal Simulations

Temperature can also reveal a lot about a reservoir’s design. How quickly/evenly does the fluid reach operating temperature? Do hot spots indicate faster fluid degradation? Do cold spots indicate stagnation?

Deaeration Simulations

Removing air from the hydraulic fluid is one of the most important roles of the hydraulic tank and return filter. These simulations determine air residence time in the reservoir, and whether it has time to effectively exit the fluid.

Sloshing Simulations

A sub-optimal tank can actually be one of the biggest contributors to air contamination! Sloshing simulations reveal if splashing within the reservoir could be trapping air in the hydraulic fluid and worsening air contamination.

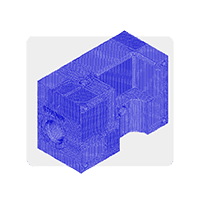

Structural Analysis

The structure of a reservoir influences not just how fluid circulates, but also whether it will deflect when full or possibly fail or become damaged when mounting or bearing further loads.

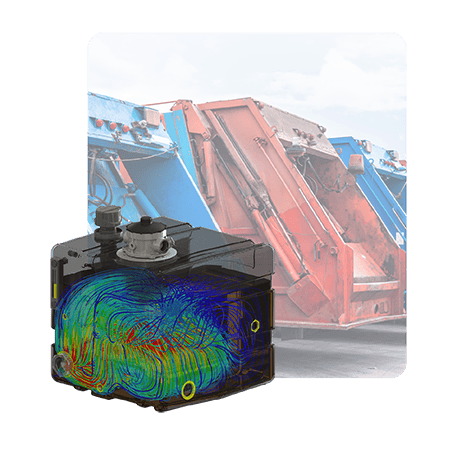

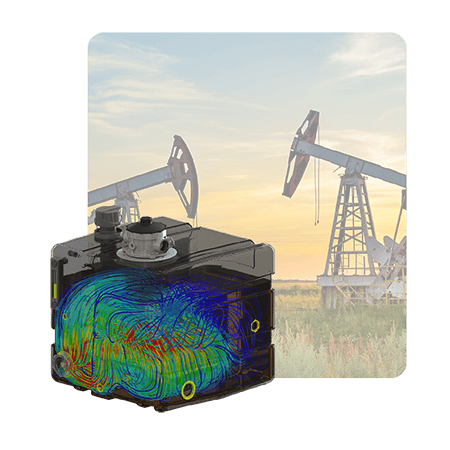

Tank Optimization In Action

Schroeder Industries has helped dozens of customers downsize their reservoirs and maximize the efficiency of their tank assemblies, reducing cost and more!

Check out the following case studies, and ask our experts about a Tank Optimization consultation:

Request a Quote – Tank Optimization

Don’t let your tank assembly be just an afterthought! Work with our experts and see what Tank Optimization can do for you: