Filtration for a More Sustainable Operation

Comments Off on Filtration for a More Sustainable OperationThere’s no sugar coating it: Industrial operations account for a large portion of CO2 generated by human activities.

In recent years, industrial operations globally accounted for nearly ¼ of carbon emissions. As a result, many companies and operations have established sustainability goals with the aim of cutting emissions and waste associated with their activities.

However, there is no single silver bullet for cutting emissions. Each sustainability roadmap takes different forms using a combination of methods for carbon reduction, from exploring alternative fuels, to conserving resource usage, and more.

One method that most industries can capitalize on for cutting carbon emissions is often overlooked: Filtration.

3 Key Ways Filtration Affects Sustainability

Whatever fluid your application utilizes—hydraulic fluid, diesel fuel, process fluid, etc—keeping it clean is vital for maintaining efficient operations. As it turns out, filtration does more than just protect your operation from downtime!

Here are the key ways that high quality filtration can make an industrial operation more sustainable:

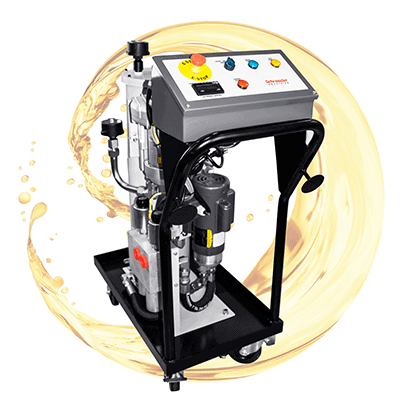

Conserving Hydraulic Oil

Hydraulic and lubricating oils are often disposed of before their usable life is up, when all they need is a little filtration! Saving just one gallon of oil saves 23.6lbs of carbon dioxide emissions.

Improving Energy Efficiency

Contaminated fluid damages components, reducing equipment performance & efficiency. Improving energy/operating efficiency through filtration is especially critical for battery-powered equipment!

Reducing Diesel Emissions

Clean, dry diesel fuel combusts more efficiently with fewer harmful emissions. Equipment that operates more efficiently also consumes fuel more efficiently. Better fuel efficiency = less diesel burned = lower carbon emissions!

Choose Your Filtration Wisely!

Not all filtration solutions are created equally, so don’t settle for less. Schroder Industries develops filtration solutions with high-end performance and sustainability in mind. Ask the experts in filtration what solution is right for you!

What is Schroeder Industries’ Energy Sustainability Initiative?

Schroeder Industries has been spreading the word about the benefits of filtration for decades. Our objective is to help our customers reduce costs and improve operational efficiency, and now, that mission includes helping reach carbon reduction goals!

The Energy Sustainability Initiative is Schroeder Industries’ mission to provide fluid power filtration solutions that contribute to a cleaner world and help organizations reach their sustainability goals. Here’s how:

Schroeder Sustainability Successes

The Energy Sustainability Initiative is more than just a lofty ideal—our solutions have made real impacts on the carbon footprint of our customers! Below is a mix of of eco-conscious ESI solutions and case studies where Schroeder Industries was able to solve real customer issues and enhance the sustainability of their practices.

Conserving Fluid Resources

Case Study L-5177: Saving Oil Through Tank Optimization

Hydraulic tanks are often inefficiently designed and oversized for their application, meaning more oil is consumed than necessary!

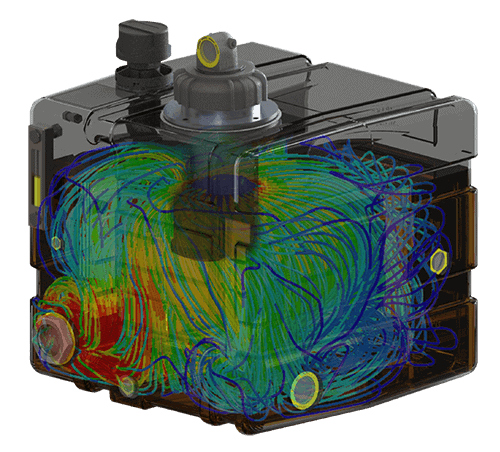

Schroeder Industries combines advanced simulations with optimized filter and reservoir solutions to create tank packages that function with less oil in a process called Tank Optimization.

Not only does this reduce cost for the customer, but by shrinking the reservoir size, oil savings compound over the equipment’s lifetime.

As we’ve already discussed, less oil = less emissions!

Here’s just one example where Schroeder Industries combined a Tank Optimization analysis with an optimized TNK tank package to make a more sustainable, efficient tank assembly:

Case Study L-5148: Revitalizing Water-Contaminated Oil

After particulate contamination, water is the most common form of contaminant in hydraulic oils and fuel.

This contamination type comes with its own hazards including lower lubricity, corrosion, and even microbial growth within diesel fuel.

Oftentimes, oil and fuel which becomes saturated is disposed of and replaced, when all it needs is filtration!

For applications with high exposure to water and humidity, this can lead to huge amounts of unnecessary carbon-intensive waste, not to mention the enormous cost and inconvenience.

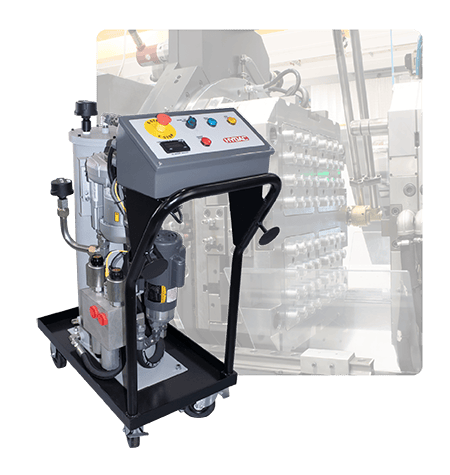

Schroeder Industries offers a variety of dehydrating solutions including combination particulate and coalescing filters, specialized dehydrating units, and more. Here’s an example of just one of those solutions, the TDSA, in action!

Case Study L-4715: Specialized Filter Element Extends Oil Life

Not all elements are created equally, and some applications may call for specialized media types.

One example is the prevalence of electrostatic discharge, or ESD, present in some systems using Group II and Group III oil blends.

These oils lack toxic and carcinogenic heavy metals, which makes them an environmentally safer substance. However, the lack of metals means the fluid is less conductive. This results in static charges that can fry the filter elements and cause a host of issues including reduced oil life.

Utilizing Anti-Stat Elements, this customer was able to multiply their oil life and take a huge chunk out of their annual carbon footprint:

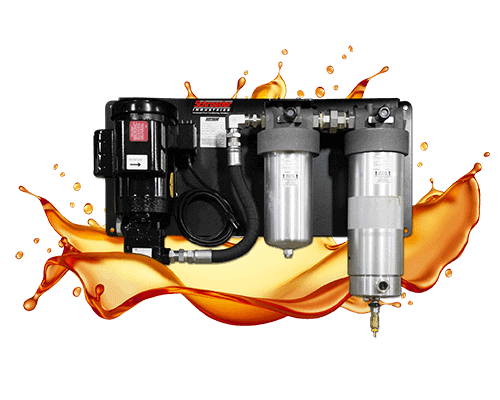

Facilitating Clean Fuel

Petroleum-based fuels are widely criticized for being a major contributor to carbon emissions, but diesel fuel will remain a primary source of energy while more sustainable technology develops and proliferates.

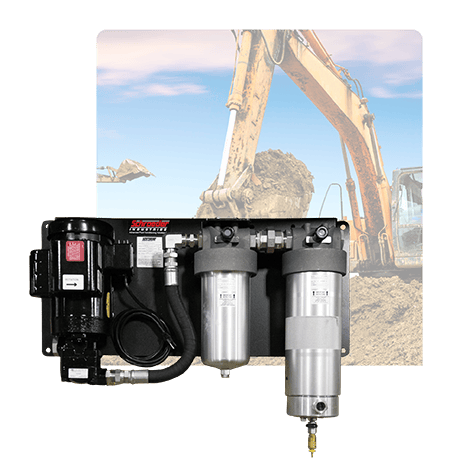

In the meantime, there are many ways that the impacts of diesel power can be reduced, including the use of biodiesel blends and DPF exhaust filters which reduce emissions from diesel exhaust.

Diesel fuel filtration prior to use can also greatly reduce emissions. Contaminated diesel fuel does not combust as efficiently, leading to lower fuel efficiency and more harmful byproducts, ultimately resulting in more emissions.

Below is an example of a customer who was able to resolve excessive emission violations simply by filtering their diesel fuel:

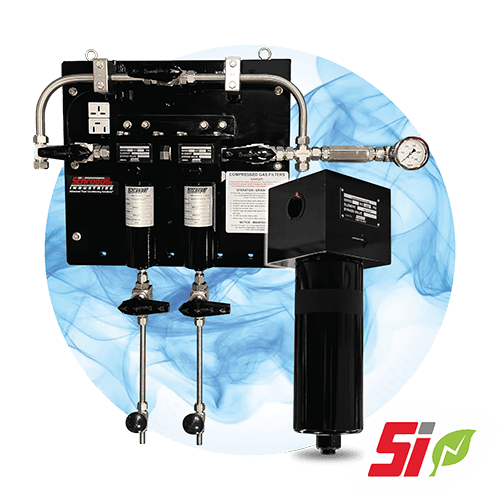

Empowering Clean Energy

Growing global energy demands and increasing concerns regarding sustainability are ‘fueling’ the adoption of alternative energy sources. Like conventional fuels, filtration is critical for ensuring high performance and longevity in equipment powered by compressed gases.

Schroeder Industries is at the forefront of filtration innovations that support this energy evolution, developing effective solutions tailored to the specific needs of alternative fuels like CNG and hydrogen.

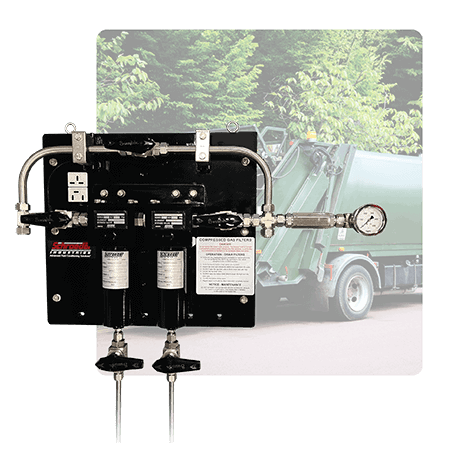

CGF Series

Filtration for compressed natural gas (CNG), one of the fastest growing and most widespread alternative fuels on the market!

GF Series

Robust, stainless steel filtration engineered for the unique needs of ultra-clean hydrogen gas and highly sensitive hydrogen engine components!

Check out the following case study to see part of the CGF Series in action!

Engineering Sustainable Solutions

Unfortunately, filtration itself involves some unavoidable waste. Filter elements, which capture particulates within the system, will eventually become full and must be discarded and replaced.

However, Schroeder Industries is always on the lookout for ways to reduce waste in our filtration product designs. Here are some of our recent innovations which re-use components that would ordinarily end up in a landfill!

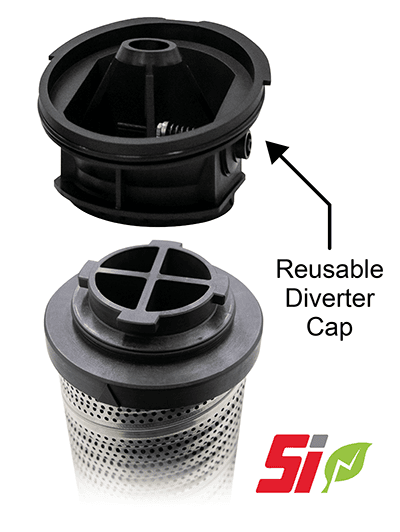

GPT Filter

Advanced cold-start protection with a unique, reusable diverter cap!

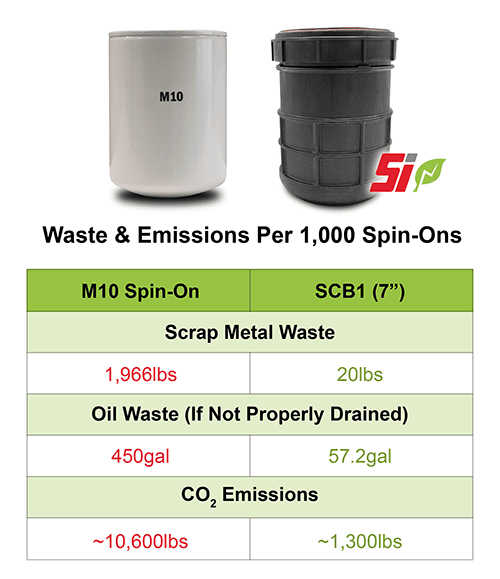

Coming Soon: SCB Filter

A cost-effective, sustainable alternative for wasteful, conventional spin-on filters!