Water Contamination Can Damage Your Hydraulic System

Water contamination in hydraulic systems is a common problem, which can severely reduce the life of hydraulic systems and fluids. If your hydraulic fluid appears milky when sampled, it’s likely that your system is experiencing high levels of water contamination.

Water ingression can occur in two primary ways:

- Ambient humidity, which can ingress into the reservoir headspace and condense into the oil. Humidity can vary depending on the location and season, so pay attention to the conditions your equipment operates in and monitor your fluid condition accordingly.

- Pre-contamination of new fluid due to poor storage. Be sure to examine any new fluid for water contamination before introducing it into your hydraulic reservoir.

Liquid contamination in your hydraulic reservoir can cause a variety of serious problems, some irreversible.

You can expect the following if water contamination isn’t controlled:

- Due to its chemical composition and density differing from oil, water can affect compressibility, impacting operational efficiency.

- Water reduces oil lubricity and can lead to varnish buildup.

- Water can also cause corrosion and oxidization in the system. Cavitation and damage to metal surfaces in the system may lead to costly replacements and increased downtime.

Trust the Experts in Water Removal & Dewatering Filtration

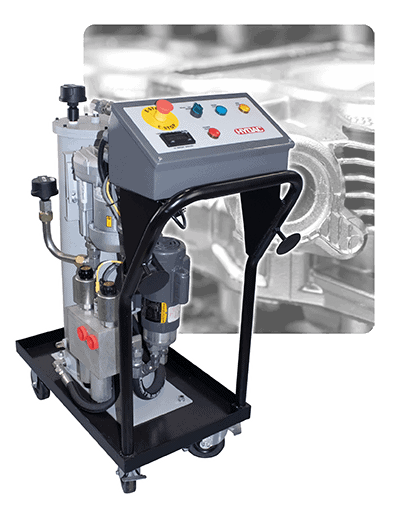

Schroeder Industries offers various products for targeting water contamination in hydraulic systems, backed by our vast expertise in fluid conditioning solutions. Our Triton Dehydrators, the TDSA and TDSE, bring proven performance across a wide range of applications where oil dehydration is needed.

The Triton Dehydration Station® series uses patented mass transfer dewatering technology to eliminate 100% of free water and up to 90% of dissolved water.

- Ambient air is conditioned to increase its water holding capability before injecting to the reaction chamber.

- Fluid is equally distributed and cascaded down through reticulated media and the conditioned air stream.

- Water is transformed to water vapor and is expelled from the unit as moist air/stream.

View the specifications of our TDSA and TDSE units below!

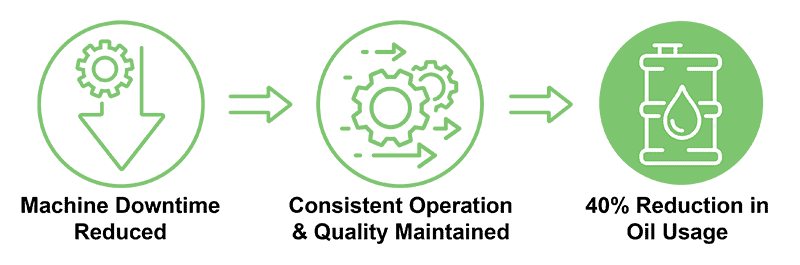

Schroeder Success: See How This Customer Saved!

Don’t just take our word on the effectiveness of the Triton Dehydration Station® series. Review the case study below to see how a real customer benefited from these advanced dehydrators!