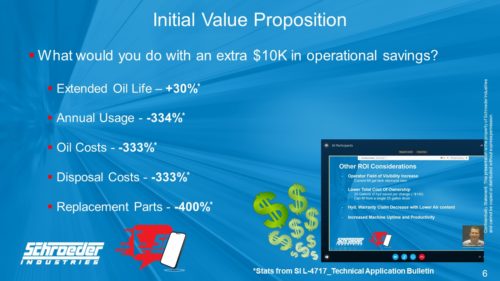

Save money on maintenance costs with a total cost of ownership (TCO) reduction strategy – Offering $10K-1M+ in optimization cost-savings in just 15 minutes!

For a complete listing of featured “Schroeder’s Fast Fifteen” solutions, click here.

Welcome to an all-new value-add program for OEM’s (original equipment manufacturers) and MRO’s (machine repair operations) called “Schroeder’s Fast Fifteen”.

In just 15 minutes, our team of hydro filter experts will bring to you suggested cleanliness solutions for critical points of solving optimization problems and offer a long run lower total cost of ownership formula.

In 15 minutes, you will learn how you can lower post ownership costs related to:

- Hydraulic filtration and oil based lube replacement

- Filter Elements with high dirt holding capacity

- Process waters

- Fuels dispensing and storage tanks

- And so much more!

Watch on YouTube “What is Fast Fifteen”.

Sign up below and we’ll schedule a time:

Schroeder Industries' Fast Fifteen Signups

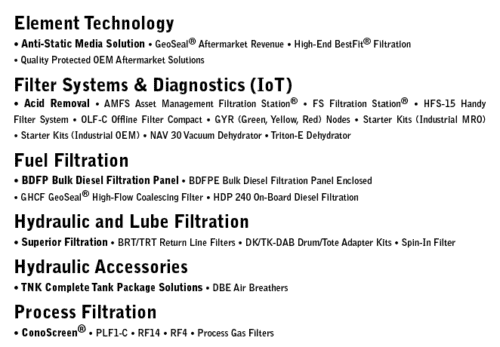

Give us 15 - we will give you targeted fluid cleanliness concepts for your machine. Some of our Fast Fifteen topics include the tools and techniques needed to achieve extended oil drain intervals w/o warranty concerns, how to reduce reservoir sizes by up to 60% through patented air removal designs, how to triple OEM aftermarket revenue programs w/ 100% OES capture, new high efficiency diesel solutions tailored for Tier IV Demands, and more!

Why Schroeder Industries:

Since 1946, Schroeder Industries has been a major contributor to the filter element and hydraulic filter housing manufacturing space.

Since then, the company has evolved to be a leading firm in the development and production of fluid conditioning equipment, including our line of plastic tanks. We design solutions for industry both OEM and MRO, industrial and mobile equipment.

Through our 75 years of experience, we have a success story in which we lower tco for just about any heavy equipment market. For a complete list of markets we serve, check out the Schroeder Industries Markets page and email us at sisales@schroederindustries.com if you’d like to see a success story for the market you serve.

From hydraulic fluids and low-viscosity fluids to process water and fuels. Our partnerships provide innovative, quick delivery products, processes, and bulk element solutions to improve performance and efficiency in our customer equipment.

How to minimize total cost:

If you choose to sit through one of our 15-minute presentations, you will receive a clear roadmap for indirect cost savings and strategies to lower total cost with machine and hydraulic efficiency.

All presentations are delivered with parallel forms reliability, ROI examples, and financial statements that will justify your time and help you improve your machine efficiency.

With 2021 marking 75 years of helping the world’s largest OEM and MRO Operations, we’ve learned a thing or two on the significant roles a hydraulic filter plays regarding machine reliability.

That is why we have archived similar results that we’re willing to pass onto you!

Our overall efficiency experts on machines that run hydraulic and lubricants, fuel and diesel fuel, as well as process water and low-viscosity fluid type of reliability are ready to answer any questions and address concerns you may be experiencing with your plant or fleet equipment.

So, what is Schroeder’s Fast Fifteen?

Schroeder’s Fast Fifteen Program is an all-new training program for OEM’s and MRO Operations. In just 15 minutes time, we will come to a meeting with you and your engineers with the knowledge we have of your company and offer you a suggested fluid cleanliness concept that can save you money and other ROI measurables. Perhaps you could benefit from one of our many aftermarket revenues programs, maybe you’re using and spending way too much money on oil, or maybe you’re noticing a decrease in system availability and an increase in maintenance repair. With our 75 years of expertise, we’re confident that we can help your already impressive operation.

Who is involved?

With 75 years of experience helping the world’s largest OEM and MRO Operations, we’ve learned a thing or two about machine reliability. That is why we have industry experts for machines that run hydraulic and lubricants, fuel and diesel fuel, as well as process water and low-viscosity fluids ready to answer any questions and address concerns you may be experiencing with your plant or fleet equipment.

Available Courses:

Initial TCO Reduction Strategy Proposition

When partnered with Schroeder Industries, a customer noticed savings in the form of a quarter more oil service life in their hydraulic turbine, a massive drop in their annual oil usage and a decrease in replacement parts cost.

Now that you know a little bit more about “Schroeder’s Fast Fifteen”, we are confident that we could offer $10K-1M+ in operational cost savings in a 15-minute time slot.

Are you interested?

Find hydraulic parts near me