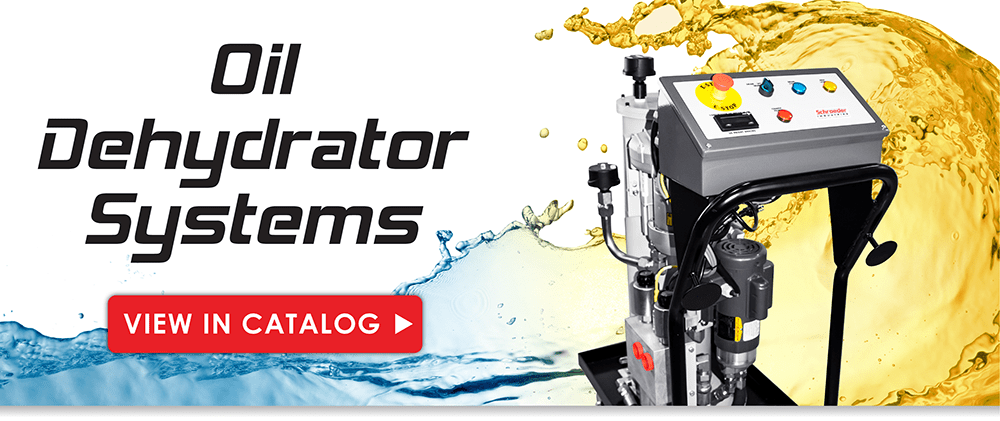

What Are Oil Dehydrator Systems?

Clean, dry hydraulic fluid is critical for optimal machine performance and protecting system components. Oil dehydration systems are specialized hydraulic filtration systems designed to remove free water and dissolved water from hydraulic fluid.

The Dangers of Liquid Contamination

Contamination of all kinds is responsible for the majority of hydraulic machine failures. Liquid contamination, such as water, will oxidize inside the system and cause corrosion of metallic components. Not only does this damage critical parts of the hydraulic system, but tiny free-floating solid contaminates caused by the corrosion will continue to wear down the system and compound the damage further.

Water contamination can come from a variety of sources. Here are just a few:

- Leaking cooler/heater and pipe work

- Filling with new contaminated oil

- Leaking hydraulic component seals

- Tank breathing (if desiccant breathers are absent or applied incorrectly)

- Pressurized water cleaning

Oil Dehydration Solutions from Schroeder Industries

In the industrial manufacturing world, preventing liquid contamination is essential. To thoroughly accomplish water removal in a system, we use either positive pressure or vacuum units.

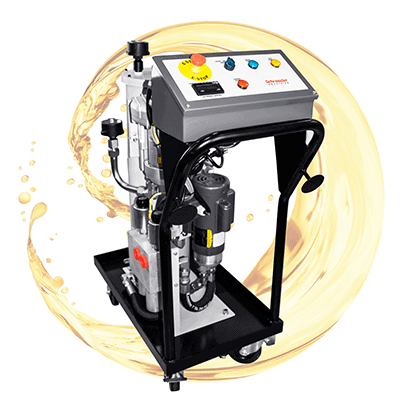

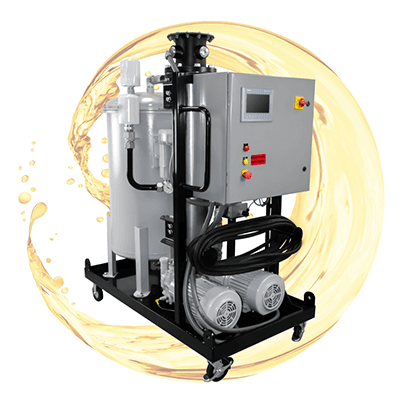

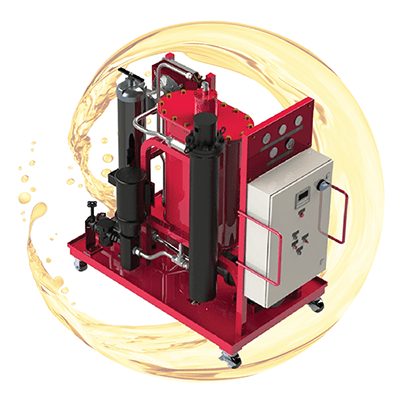

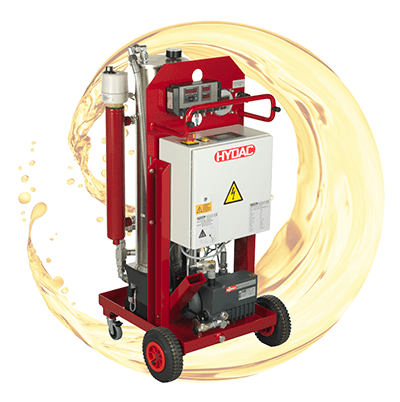

At Schroeder Industries, we have four (4) machines engineered specifically for oil dehydration:

View Product Options:

Positive Pressure and Vacuum Dehydration, How Do They Work?

There are many hydraulic oil machines that only remove free water. All of Schroeder’s Dehydrating Units remove both free water and entrapped/dissolved water from the oil.

Our vacuum options can also remove dissolved gases.

Positive pressure is when ambient air is conditioned through our patented process to increase water holding capabilities before being introduced to a reaction chamber.

In the reaction chamber, the wet oil meets conditioned air (air conditioned by an external hydraulic filter) and the water transfers to the air.

The water vapor is then expelled from the unit with the air as a moist air stream. Dry oil is then returned back to the system.

This positive pressure dehydration technology is found in our Triton Dehydration Station® Series.

Vacuum dehydrator for oil removes free and dissolved water and gases. This includes any other particle that could affect your oil.

Our vacuum technology uses ambient air, combined with reduced vapor pressure in the reaction chamber, to effectively remove the water and gases from the oil. The water and gases are condensed and collected for disposal while the dry oil is returned to the system.

What Industries Can Oil Dehydrators Be Applied To?

Power Generation

- Turbine bearing lubricants

- Electro-hydraulic control system (EHC) fluid

- Boiler feed pumps lubricant

Pulp & Paper

- Press and dryer section cylinder bearing lubricant

- Calendar section hydraulic fluid

- Powerhouse generator turbine location

Steel

- Hot and cold rolling mill bearing lubrication

- AWC & AGC systems