From: Schroeder Industries’ Fuel Filtration Center of Excellence

For those of us in the Northern hemisphere, Fall has arrived!

For our friends in the Southern hemisphere, October brings the welcoming warmth of Spring and return of the rainy season.

As we transition through the change of seasons, the diesel fuel blends in many regions will soon change as well to accommodate the lower or higher temperatures.

This is a great time to do preventative maintenance, clean, polish, and upgrade fuel systems where needed.

Additionally, many of our customers are reviewing their year-end budgets and may find that they have funds remaining that could be allocated to make those system upgrades and improvements.

With that in mind, it’s critical that fuel-coalescing and particulate removing solutions be integrated into ALL fuel polishing, transfer and clean-out systems.

The GHCF, GHPF, BDS particulate and coalescing filtration, along with the bag filters we offer utilize the same replacement elements across the Fuel Filtration Product Lines. This makes reordering filter elements simpler while providing better and higher performing systems than our competitors do.

Filter Cart Systems / Mobile Filtration Units

The BDFC Bulk Diesel Filtration Cart provides exceptional single pass or kidney loop filtration with both high efficiency particulate and coalescing filtration integrated into one compact filter cart.

The BDFC is ideal for fuel maintenance operations.

It is portable and very easy to use and operate.

Offers flow rate options of 14 gpm (53 l/min) or 25 gpm (95 l/min).

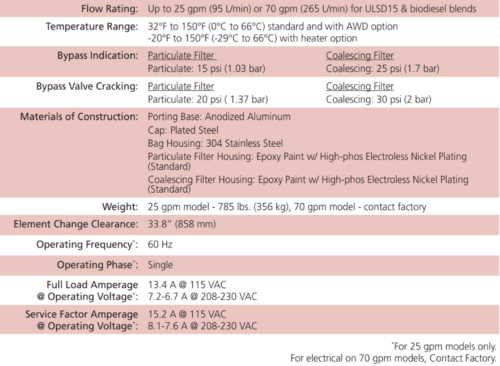

The BDC Bulk Diesel Cart offers higher flow rate options with considerably more dirt holding capacity and throughput for larger operational needs for fuel polishing.

These systems are available in standard flow rated options of 25 gpm (95 l/min) or up to 70 gpm (265 l/min)

The BDC incorporates the BDS particulate and coalescing solution along with a bag pre-filter.

These systems are ideal for environments experiencing microbial growth or blooms or for higher capacity systems where larger throughput and capacity is required. The three integrated filters combine the economy of a bag element with Schroeder’s high performance synthetic media and our patented water removal technology.

It’s important to note that these systems are all designed to operate on North American electrical standards.

We understand these are not the same globally; therefore, we have designed these systems with slotted mounting holes designed to accommodate NEMA-style motors, which allow for easy adaption of these systems in other parts of the world.

They can be shipped with or without pump and motor groups to enable local sourcing and installation to match regional electrical requirements. We also have the ability to ship these units complete with your local requirements, but this would require a minimum purchase of 10 pcs to accommodate that request.

For more information about diesel fuel cleanliness specs as well as past successes we have had with applications utilizing these products, please contact us.