Harmful Varnish Is On The Rise

As hydraulic oil oxidizes and degrades, a sticky substance known as varnish is deposited throughout the hydraulic system. Changing oil chemistry in modern hydraulic systems and the high pressure & temperatures achieved during equipment operation are leading to increased varnish deposits.

How Does Varnish Affect Your Hydraulic System?

Varnish accumulation in a hydraulic system causes a variety of potentially serious issues:

VEU Compact: Bust Varnish Before It Can Tarnish Your Equipment!

The new VEU Compact has been specially engineered to tackle varnish and protect hydraulic systems from its harmful effects. As the risk of varnish contamination and related problems proliferate, having a specialized filtration solution can save you and your system considerable trouble.

More Solutions For Banishing Varnish

Schroeder Industries is no stranger to the effects of varnish, and the VEU Compact isn’t the only solution we have to offer. Learn more about our other specialized varnish removal systems!

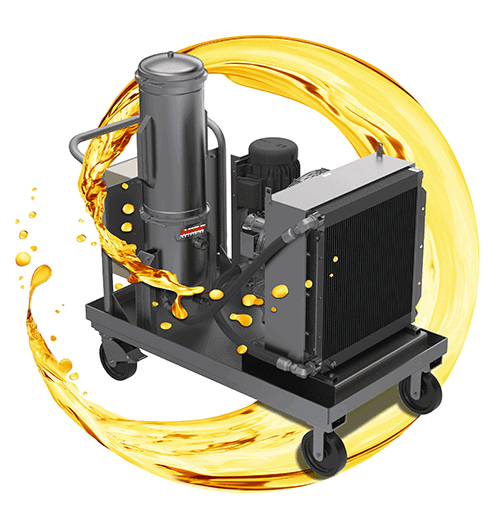

VEU – Varnish Elimination Unit

The service-friendly Varnish Elimination Unit (VEU) is used to prepare mineral oils and is particularly effective at removing varnish. By reducing the oil temperature with an onboard cooler, the VEU allows for exceptional varnish precursor extraction.

VMU – Varnish Mitigation Unit

Available as both a complete service unit and modular system for retrofits, the VMU traps varnish particulates on the surface of an active filter element via adsorption