‘Will-Fit’ Doesn’t Cut It

Keeping a hydraulic system free of contamination is critical for system efficiency and longevity, and high quality filtration elements are the key to contamination control. Unfortunately, it’s not uncommon for customers to seek out low-cost, off-brand imitations of Schroeder Industries filter elements in order to cut down on expense.

Not all filter elements are created equally, and just because a given element fits in a Schroeder filter housing, it doesn’t necessarily provide adequate filtration. Cut-rate imitations may claim that “All filtration elements are guaranteed to meet or surpass all specifications of the original equipment manufacturer” but that’s not always the case. Take a look at the numbers below and see for yourself:

| Elements | Schroeder KZ5 | “Will-Fit” replacement |

| # of pleats | 80 | 71 |

| Pleat Height (in) | 0.63 | 0.61 |

| Media Layers | 6 | 5 |

| DHC (g) | 119 | 84.3 |

| Beta 200 | 4.8 | 12.2 |

| Beta 1000 | 6.3 | 18.1 |

| Elements | Schroeder 27KZ1 | “Will-Fit” replacement |

| # of pleats | 80 | 71 |

| Pleat Height (in) | 0.63 | 0.61 |

| Media Layers | 6 | 5 |

| DHC (g) | 378.1 | 233.1 |

| Beta 200 | <4 | 12.4 |

| Beta 1000 | <4 | 18.3 |

Cheaper knockoff filter elements trade functionality for lower cost, exposing the hydraulic system to increased risk of contamination, machine downtime, and system failure. Furthermore, the blame for these failures may be wrongly placed on the housing manufacturer, not the cut-rate filter element.

How can we ensure that proper, high-quality filtration elements are being used?

Quality Protection: Guaranteeing High Quality Filter Elements, Every Time

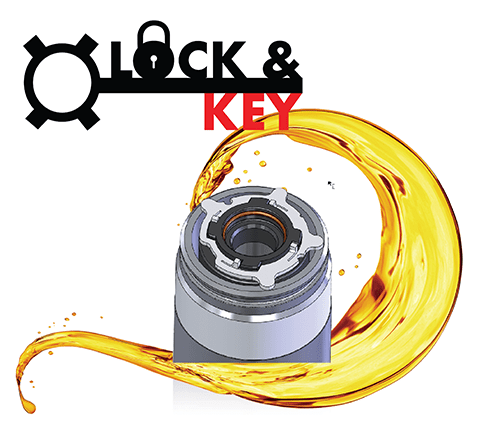

Quality Protection is Schroeder’s answer to the problem of mismatched, inadequate elements. The patented, premium Quality Protection elements are engineered specifically for superior performance when paired with Schroeder filter housings.

What does Quality Protection mean?

- End users cannot substitute “will-fit”, low quality elements for a Quality Protection element

- OEM’s will capture aftermarket revenue from Quality Protection elements; exponential growth year after year

- Increase in machine productivity and reliability when Quality Protection filtration elements are deployed

- Overall reduction in warranty claims when hydraulic equipment is protected by superior filtration

Why Do My End Users Need Quality Protection?

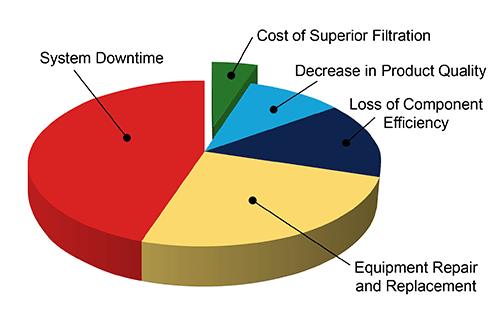

Hydraulic system downtime and repairs represent a significant portion of overall costs to equipment end users. Contamination is the leading cause of hydraulic machine downtime, accounting for as much as 70% of premature machine failures. Ensuring the highest quality filtration protects your end users’ equipment from contamination-related failures and associated costs.

How Does Quality Protection Benefit My Business?

Quality Protection is the clear choice for protecting your end user’s hydraulic equipment from contamination-related damage, but how does it benefit your business directly?

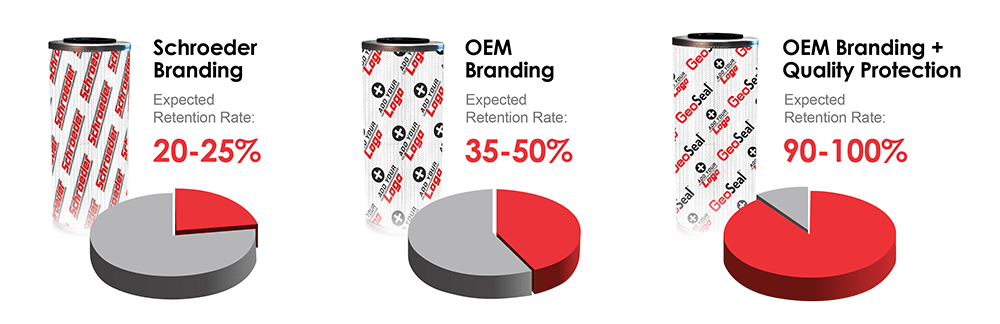

Not only will your equipment perform at like-new levels, but Quality Protection can also provide an increase in aftermarket retention year over year. By taking advantage of our Quality Protection filter elements with the private labeling option, you may see up to 90-100% aftermarket retention. Compare this to the expected retention when using standard Schroeder elements with or without private labeling.

Over a 10 year period, one may sell an estimated triple the quantity of filter elements when implementing a Quality Protection strategy than without. The associated boost to sales margins makes this a highly profitable, winning strategy.

Quality Protection Solutions

Private Labeling Solutions

Incorporating a private labeling program has proven benefits for aftermarket element business retention, and offers additional protection against inferior, cut-rate filter element substitutions. Schroeder offers a full line of branding solutions for filter elements, including our Quality Protection items. Review our Private Labeling Capabilities Form and email sisales@schroederindustries.com to plan your private labeling program!