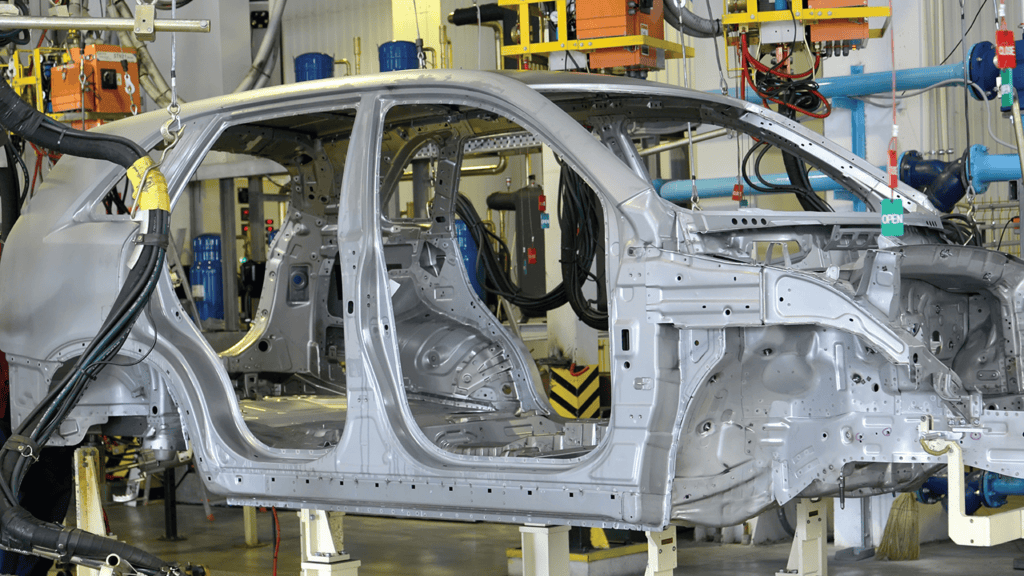

Hydraulic and Process Filtration Solutions for Automotive Manufacturing Applications

Automobiles are the heart of personal transportation, as well as providing a huge role in commerce. Automotive manufacturing encompasses a massive network of manufacturing, machining, and assembly environments.

Filtration helps maintain the quality and efficiency of the equipment used in the automotive manufacturing process!

Find Schroeder Industries Filtration Solutions For:

Spotlight: Roll-Off Cleanliness

Operations that product automobile components or assemble and ship vehicles have to watch out for built-in contamination.

If components are not properly cleaned, safely stored, and checked for contaminants before assembly, damaging solid contamination can be literally built in to the finished product! This can have disastrous consequences for end users, as built-in contamination can damage their vehicle the moment it leaves the assembly line, resulting in costly repairs.

Leftover machining debris, ambient dust and grit that settles on stored components, and insufficiently clean assembly conditions can all lead to built-in contaminants. If vehicles experience issues due to built-in contamination, warranty claims, negative brand reputation, and even legal challenges can ensue.

Ensuring a high standard of Roll-Off Cleanliness can help protect your business and ensure customer satisfaction!

Interested in component cleanliness testing, but unsure where to begin? Our cleanliness experts can help.

Featured solutions for your fluid conditioning and filtration needs!

Automotive Industry Case Studies

Anti-Stat Media Eliminates ESD, Saves 30K+ Gallons Oil Annually

When an automotive plant noticed their oil lifespan dropping by 80%, they contacted Schroeder Industries.

The culprit was quickly identified: Electrostatic discharge, also called ESD.

ESD can cause damage to filter elements, slashing their efficiency and even causing the element to fail completely. This not only allows contamination to flow freely, but can actually contribute to solid contamination as the element degrades!

By deploying a purpose-engineered anti-static filter element, called Anti-Stat Media, Schroeder Industries was able to bring new life to the customer’s oil!

Here’s how Anti-Stat Media benefited this customer:

Oil Service Life Increased +4 Years

+31.7K Gallons of Hydraulic Oil Saved Annually

Nearly 750K Pounds of CO₂ Emissions Saved Annually

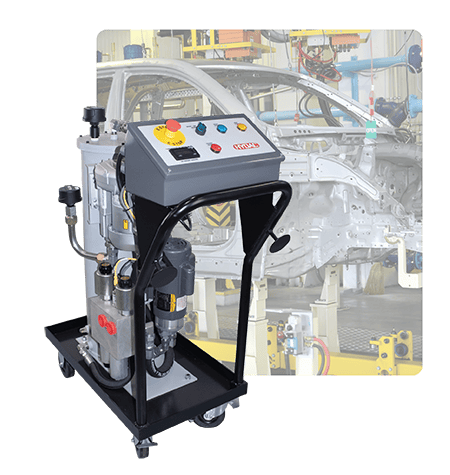

TDSA Dehydrator Addresses Water Contamination Without Additional Downtime

A customer operating in the automotive manufacturing space discovered high levels of water contamination in the operating fluid of their hydraulic press.

While the customer needed to address the water contamination to prevent damage and downtime, they couldn’t afford to delay the delivery of critical vehicle components. So, they needed a dehydrating solution that could operate quickly and with minimal interference to the hydraulic press.

Schroder Industries first deployed a TDS-E unit through the equipment rental program to immediately address the customer’s needs. Afterwards, the customer purchased a TDS-A unit to address water contamination moving forward.

Here’s how the Triton Dehydration Station® technology benefited this customer:

Equipment Downtime Reduced

40% Reduction in New Oil Consumption

Machine Integrity/Parts Quality Maintained

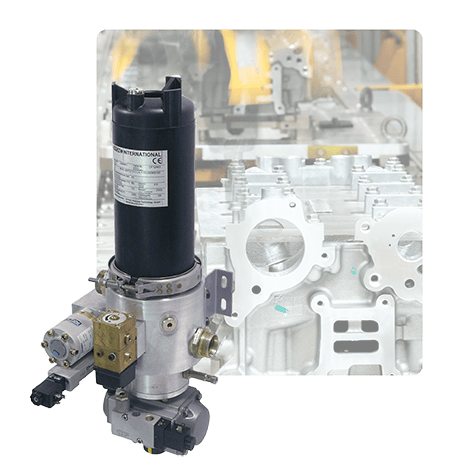

AutoFilt® RF4 Increases Uptime, Reduces Expenses for Automotive Manufacturer

An automotive manufacturer struggled with wear and tear in their equipment during the cutting and grinding of machine components, causing excessive element and fluid replacements.

Time is money in the automotive manufacturing business, so reducing any possible downtime is paramount for efficient, profitable operation.

An AutoFilt® RF4’s automatic backflushing automatically clears the element with minimal interruption to filtration. By implementing an RF4 as a secondary protective filter to the screw pumps feeding fluid to the machine tools, Schroeder Industries was able to minimize contamination-related issues.

Here’s how the AutoFilt® RF4 benefited this customer:

Element & Machine Component Expenses Reduced

Savings up to 50K Per Minute of Reduced Downtime

Automotive Plant Productivity Increased

You could be Schroeder’s next success story! Let us know how we can help.

How can we improve your filtration & equipment performance? Ask the experts!

Request a Quote:

Ask the experts!