Electric Hydraulic Systems: The Future of Hydraulics

The mobile hydraulics industry is going through a major transformation – moving towards electric hydraulic systems. Electric hydraulic systems hold the potential to be drastically more energy efficient than the typical hydraulic systems that exist today.

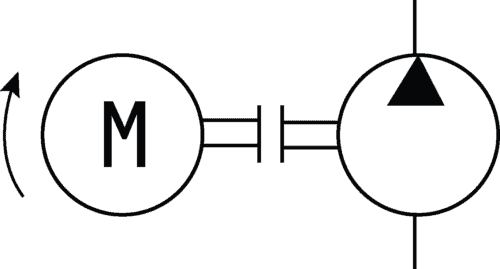

To simplify how this is possible, electric hydraulic motor-pump units only operate when flow and pressure are required to perform the working task at hand.

When there is no flow or pressure required, the electric hydraulic motor-pump unit switches to zero energy-mode, saving the consumption of energy and increasing the system’s efficiency. This is what we call Energy efficiency.

Energy efficiency simply refers to the process of reducing one’s system energy. This can be achieved by lowering the amount of energy consumed to accomplish an equivalent output (e.g. halt of use when not in operation).

Think about some of the newer car models in the market today.

Some of the higher-end models shut down every time the car stops at a stop light. Since the car is in idle at that stop light, why would the car continue to place tension and wear the performing components when they’re not performing their sole duty – to drive?

This theology and way of thinking is slowly creeping into hydraulics too. Experts are now looking at ways to incorporate these (and other) types of electric energy to power hydraulic machines.

This is called electric hydraulics.

With the rising trend of electric drive vehicles and utilizing efficient energy throughputs, there is now a need to reduce power consumption and extend the battery life through increased hydraulic efficiency.

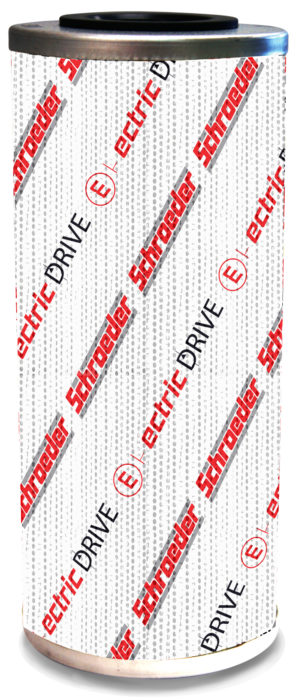

That is where Schroeder’s Electric Drive media can help.

The use of Schroeder’s GREEN, Electric Drive (E-Drive) Media filtration technology guarantees safe and reliable equipment operation, all-while conserving the use of energy.

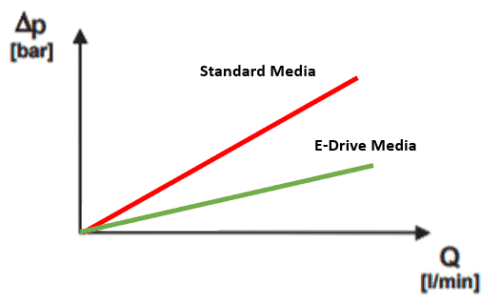

Part of Schroeder’s Energy Saver initiative, filter elements made using the all-new E-Drive Media are characterized by an unusually low pressure drop, making them suitable for low energy requirements compared to conventional hydraulic elements under the same ambient conditions.

E-Drive Media is the clear choice for use in electric hydraulic drive motor-pump units. Use it for conserving energy bills and wherever high viscosity fluids are employed – especially at low temperatures that produce a cold start behavior.

Schroeder’s E-Drive Energy Saving Features:

- Retains low resistance of flow to reduce the ΔP across the element.

- The filter media construction consists of multi-layered, synthetic fiber material with support.

- Great for cold start conditions where a low pressure drop is required.

Technical Specs:

- Element Collapse Rating: 145 psid (10 bar)

- Temperature Range: -22°F to 212°F (-30°C to 100°C)

- Flow Direction: Outside to Inside

E-Drive Media is currently rated for 8, 10, & 15 µm filtration.

To see if Schroeder’s Energy Saving Initiative E-Drive Media can be the right solution for your electric hydraulic systems, email us at sisales@schroederindustries.com or leave a comment in the blog post below.