Compressed Natural Gas, or CNG, is one of the best known and most widely used alternative fuel options currently available. As CNG and CNG-powered technology escalates, filtration is necessary to ensure optimal fuel quality and operational efficiency.

In this post, we will explore:

CNG Surge: Compressed Natural Gas Market Projected to Grow

According to a June 2023 report from The Business Research Company, Compressed Natural Gas Global Market Report 2023, the global CNG market was valued at 147.16 billion USD in 2022. By 2027, the market is expected to grow 83.5%, for a total estimated value of 269 billion USD.

CNG is one of the major players in alternative fuels for several reasons, including:

1. Improved sustainability compared to traditional fuels.

CNG burns cleaner than traditional gasoline and diesel fuel. CNG engines reduce greenhouse gas emissions by up to 20% and cut toxic emissions overall, including up to 97% reduction in carbon monoxide versus gasoline.

2. Abundance and power of natural gas.

Natural gas is one of the most widely abundant and relatively cheap alternative fuels, making it cost effective to produce and utilize.

It also delivers comparable torque and power to traditional diesel engines, making it viable for intensive work such as construction and mining.

3. Relative ease of integration into current systems.

CNG can largely utilize existing technology such as vehicle designs and transportation infrastructure, making transitions and retrofits more straightforward compared to other alternative fuel sources, such as electric power.

Part of this growth in the compressed natural gas market is being driven by CNG fueling and other related applications, including power generation and fueling CNG-powered vehicles for commercial fleets. Delivery vehicles, refuse collection trucks, and other commercial vehicles are seeing increased adoption of CNG. Compressed gas dispensing stations and virtual pipelines are expanding to satisfy the growing need for CNG fuel.

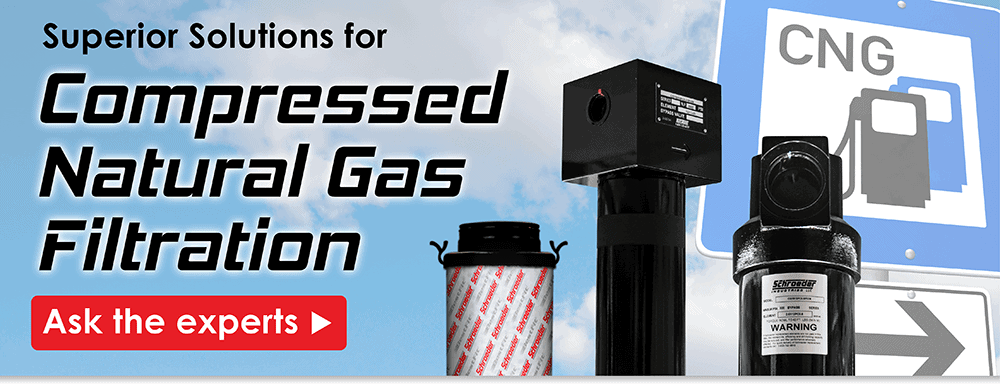

In order to ensure optimal performance of both CNG dispensing units and the vehicles that utilize it, CNG must be filtered to remove damaging contamination such as water vapor, residual oils, and solid particulates.

CNG Filtration 101

Despite being a compressed gas, CNG is also susceptible to contamination and requires filtration just like diesel and conventional liquid fuel to maintain its quality.

Just like conventional fuel contamination, contaminated CNG can negatively impact equipment and its performance:

However, filtering compressed gas requires extra consideration compared to conventional liquid fuel. Adequate gas filtration must, among other things:

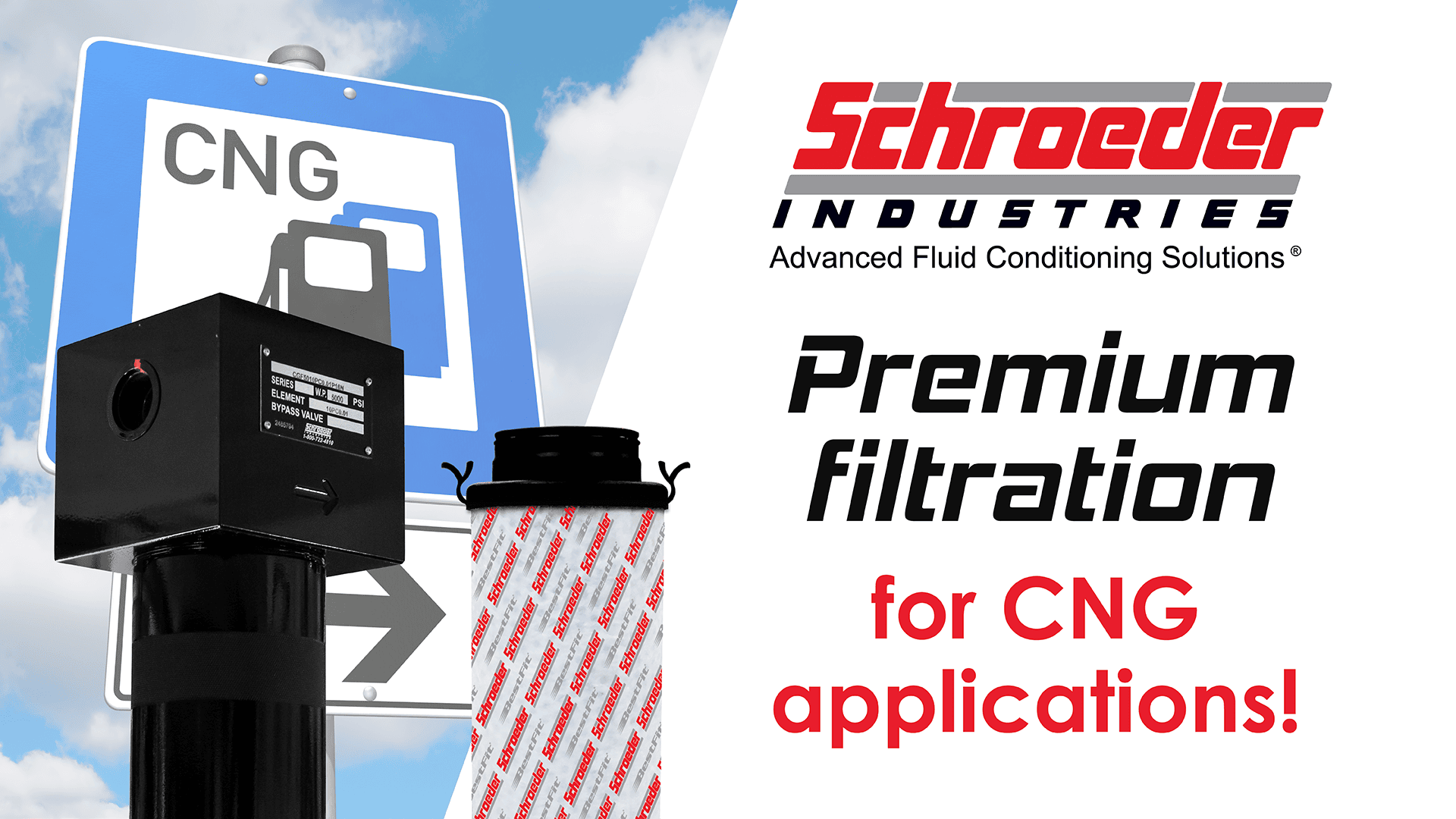

CNG Filtration Solutions from Schroeder Industries: Engineered for Excellence

Schroeder Industries offers comprehensive solutions for CNG filtration and filling stations, from generation to dispensing.

Generation

Transportation

Storage

Dispensing

Learn more about our CGF Series for CNG filtration, as well as our premium replacement elements!

Compressed Gas Filters

Compressed Gas Filter Panel

Replacement Elements

CGF Series: Beyond CNG

The versatile CGF Series also offers exceptional performance in other compressed gas applications besides just CNG!