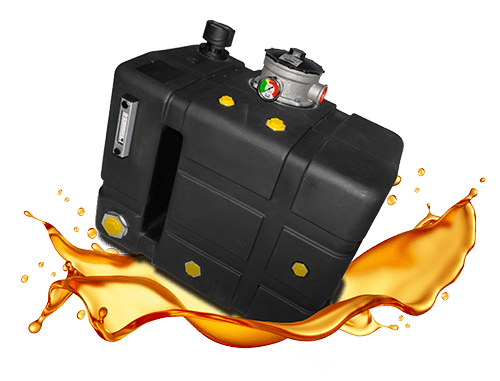

Schroeder Industries’ TNK series is built for exceptional durability in a wide range of working conditions.

Lightweight, Ultra Durable Hydraulic Tank Packages

The TNK Series offer complete hydraulic reservoir solutions with pre-installed accessories, gauges, and air breathers. These reservoirs are engineered to last and increase your equipment’s efficiency.

With 4, 7, 12, 18, and 25 gallon options with potential for custom solutions, there’s a TNK for every system! Pair with Air Fusion Technology (AFT) to boost air filtration capabilities and even downsize your reservoir requirements.

Features and Benefits

Dynamic Duo: Pair TNK with Air Fusion Technology (AFT) to Maximize Air Filtration & System Efficiency

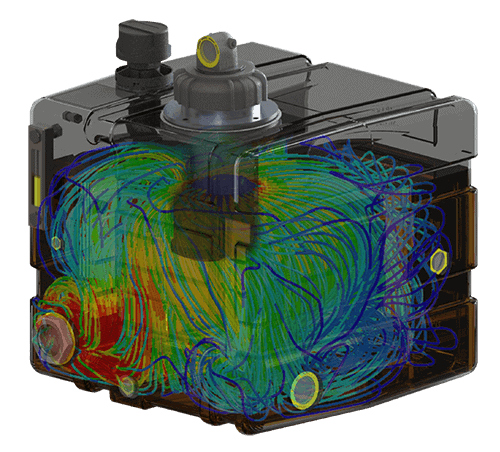

The TNK’s design already enhances degassing, and paired with filtration powered by Air Fusion Technology, air filtration is greatly augmented and system efficiency can be increased.

Air Fusion Technology, or the AFT, is engineered to maximize air filtration:

- Compared to a standard filter, the AFT reduces air in the suction line by 20% on the first pass. Superior air filtration increases the reliability and efficiency of your equipment, saving you costly downtime.

- The AFT’s low pressure drop and exceptional air filtration capabilities allow for smaller reservoir sizes—even downsizing by up to 60%! This creates room for additional batteries or a larger fuel tank, allowing your system to get the most out of its fuel source.

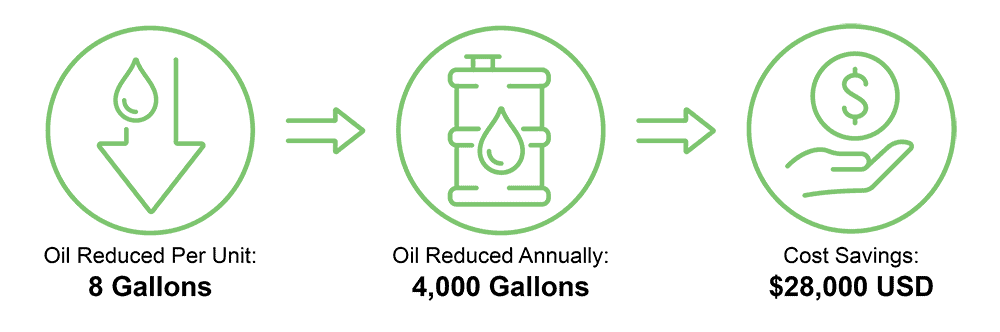

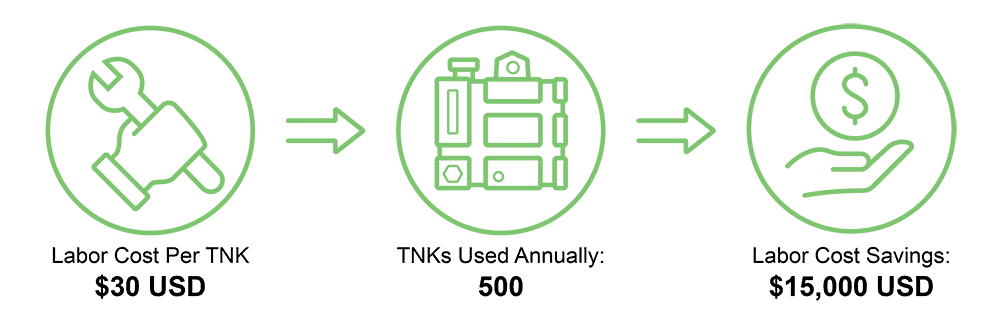

Ideal for Tank Optimization

Tank Optimization is the process of reducing reservoir size, and thus fluid volume, to improve system efficiency. There are many benefits to optimizing your hydraulic tank, including: