Spring is officially here, and while many welcome the warmer weather, spring conditions can bring higher risks of contamination. (And no, we’re not just talking about allergens!)

One specific phenomenon, ‘cottonwood season,’ poses a particular risk for industrial operations using cooling towers, open loop systems, and other process fluid systems exposed to the outside air.

Cottonwood Season: The What, Where, and When

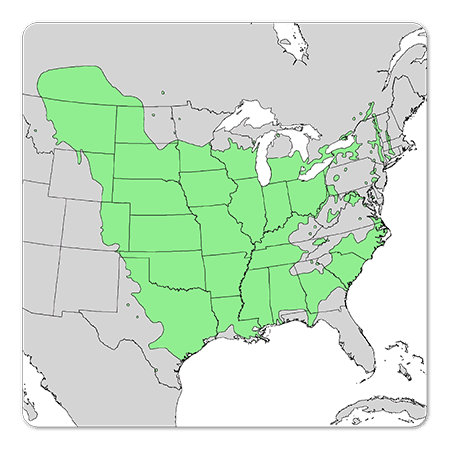

The eastern cottonwood tree, which is native to a large portion of the United States and parts of Canada, spreads using fibers that carry its seeds on the wind—hence the name ‘cottonwood.’ The resulting drifts of white fluff can be so dense that they look like out-of-season snow.

Cottonwood season typically starts later in the spring, beginning late in April or early May, and finishing in the early summertime. The amount of cottonwood seed and fiber can vary by year and based on environmental conditions. Occasionally, when conditions are right, a mast seeding event can result in much higher amounts of seeds and fluff than normal.

While all this cottonwood fuzz looks pretty innocent, for industrial operations near cottonwood trees, all that fibrous fluff can cause some pretty serious problems.

How Can Cottonwood Fluff Affect Your Industrial Operation?

The flurry of cottonwood seeds and fiber can cause major issues for industrial operations in the affected area, including:

How Can I Prevent Cottonwood Season Damage?

Because the main threat of cottonwood season is particulate contamination from the cottonwood seeds, robust process filtration offers the best protection.

Schroeder Industries’ AutoFilt® filtration products excel in capturing large quantities of contaminants in process fluid streams, and the RF14 in particular is our expert recommendation for cottonwood contamination scenarios:

Schroeder Industries – AutoFilt® RF14

Don’t just take our word for it: Check out the case study below where a customer struggling with cottonwood fibers got back on track with an AutoFilt® RF14!

Concerned About Cottonwood Contamination? Schroeder Industries Has You Covered!

Tell us about your application and any issues you’re concerned about, and the experts at Schroeder Industries will work out a solution for your specific needs! Our Process Filtration division has the tools you need to keep your operation flowing smoothly.