When it comes to contamination, what you don’t know could be costing you.

In hydraulic systems, up to 70%-90% of wear and failure is contamination related!

To keep your equipment functioning properly, slash repair costs, and operate as efficiently as possible, contamination control is essential. The effects of contamination costs tens of thousands, even hundreds of thousands of dollars for industrial operations across the world every day!

Every person dealing with hydraulic equipment, diesel-powered equipment, and even compressed gases should know some contamination basics.

Let’s review solid contamination, ISO Codes, and ISO Targets, some of the most fundamental principles of contamination control.

Recap: Solid Contamination

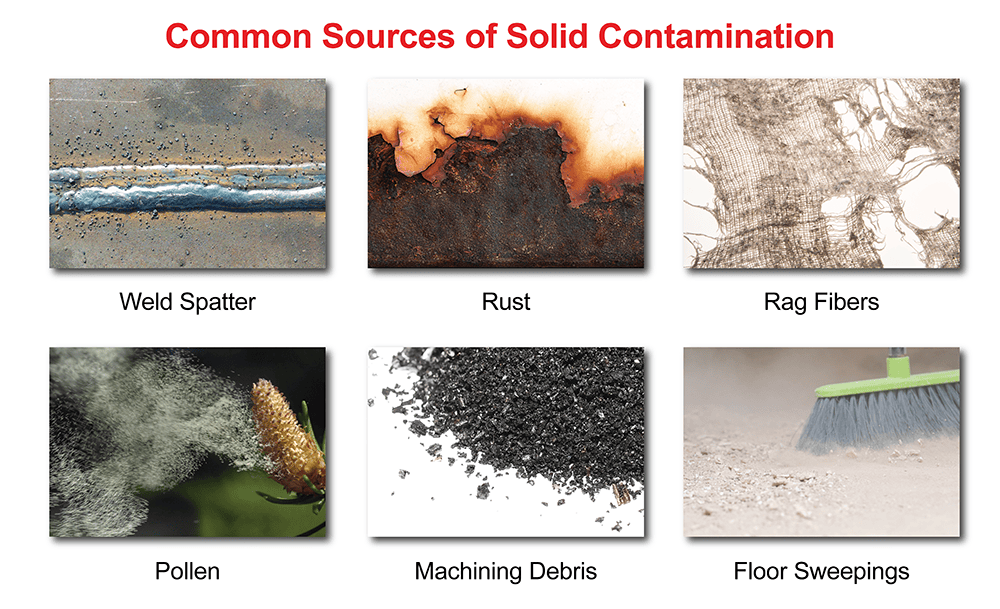

Solid contamination is the most common, and often the most destructive form of contamination in fluid-powered systems. There are countless opportunities for solid contamination to infiltrate hydraulic fluid, diesel fuel, and other operating fluids:

Solid contaminants are often smaller than the eye can see, but these tiny particles can add up to huge losses in efficiency, productivity, and profit!

In the world of fluid power, solid contaminants are measured in microns, often represented by the symbol ‘µm’. Microns are used to measure particles on the microscopic level.

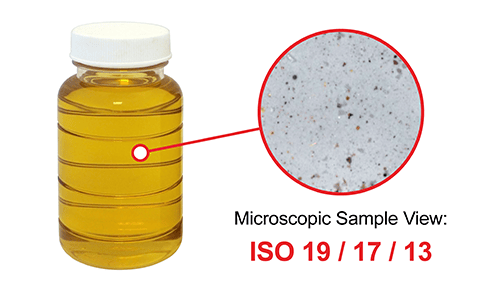

While a sample of hydraulic oil or diesel fuel might look perfectly clean at a glance, under a microscope, the hidden danger becomes obvious. These solid contamination particles may be incredibly small, but their impact on your machines can be massive!

As microscopic particles of solid contamination grind through your system, they gradually wear down critical components like servo valves, pumps, cylinders, injectors, seals, and more.

When these components eventually fail, the repercussions can range from inconvenient, to costly, to catastrophic for productivity and even worker safety!

Knowing how how to measure solid contamination—and how much contamination your system can handle before risking premature failure—is incredibly important.

ISO Codes: Decoding Solid Contamination

The amount of solid contamination in a fluid system or a fluid sample is represented by an ISO Code.

ISO Codes (pronounced ‘eye-so codes’) are numerical codes used to quantify the amount of solid contamination in hydraulic fluid, diesel fuel, process fluid—essentially, any operational fluid!

ISO Codes consist of three numbers, separated by forward slashes. These three numbers represent the amount of solid particles across three different size ranges in the fluid.

Higher numbers in an ISO Code mean more contamination in the fluid!

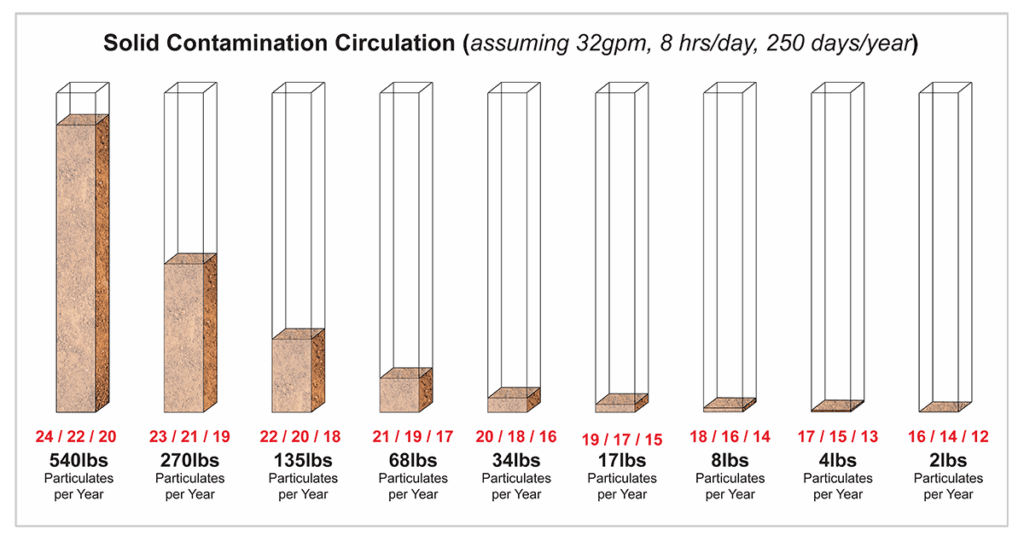

Additionally, with each increase in ISO Class, the amount of contamination is actually doubled. So, if your hydraulic system starts at ISO 16 / 14 / 11, and goes up to ISO 17 / 15 / 12, there is twice as much solid contamination grinding through your system every time you turn it on!

This means that what may seem like a small change in your ISO Code can have huge impacts. Just a few rungs up or down the ISO Class ladder can mean the difference between tens or even hundreds of pounds of solid contamination circulating in your system every year!

If your machine is operating with dirty fluid, this could take years off its life in terms of peak performance. This is why knowing and meeting your machine’s cleanliness targets, also called ISO Targets, is so important!

Tolerances and ISO Targets

ISO Codes are also used to represent part tolerances.

‘Tolerance’ refers to how much contamination a machine component can tolerate and still maintain a ‘normal’ lifespan according to manufacturer guidelines.

Components that are more complex, more sensitive, or located in higher-pressure regions of the fluid circuit, etc. will generally be less tolerant to contamination.

Because tolerance is represented by an ISO Code, an individual component or system’s tolerance is commonly called an ISO Target.

An ISO Target is basically the ISO Code you should aim for in your operating fluid to help your equipment live up to its potential!

Different components within a system may have different tolerances, and thus, different ISO Targets!

The ISO Target for an entire machine or system is based on the component with the lowest tolerance. That way, protection is ensured across the whole system for even the most sensitive component!

How Can I Find My Machine’s ISO Target?

Manufacturer guidelines generally include a minimum ISO Target.

However, a custom assessment could find a target that helps your equipment outlive its expected operational life!

A manufacturer may set a machine’s ISO Target based on a ‘normal’ lifespan for different components.

But, if you can push your fluid cleanliness beyond the manufacturer’s minimum recommendation, it may add years of efficient performance to your machine’s life!

Want to find out if your equipment could go above and beyond its normal operating life?

Talk to the experts at Schroeder Industries! We can provide a comprehensive analysis of your current ISO Targets and contamination control program, and make customized recommendations that help your equipment live up to its full potential.