Coolant System Monitoring Just Got Simpler

Comments Off on Coolant System Monitoring Just Got Simpler

Coolant systems are a staple at virtually all major manufacturing and power plants, protecting the vital equipment resources from the effects of overheating. However, maintaining a coolant system is incredibly time consuming.

With any coolant system, the operator needs to perform daily checks of the tank volume, adding fresh emulsion if necessary. Manual checks of the fluid concentration must also be done daily and re-dosed if needed.

These steps are tedious, time consuming, and resource intensive—but are critical to maintaining tool life. If the concentration of coolant falls by just 2%, the equipment’s service live can decrease by up to 40%. Coolant System Monitoring Just Got Simpler!

Introducing Automated Coolant Monitoring Solutions

To simplify the tedious process of sustaining a coolant system, Schroeder Industries is proud to introduce these unprecedented, automated solutions: The FCU5000 and FC5000.

These sophisticated, automated coolant management tools are calibrated to deliver the appropriate amount of coolant when necessary, preventing overdosing of coolant and controlling concentrate usage. Automated alert configurations keep you informed and ready to respond to any potential issued with the coolant system.

Fluid Control Unit – FCU5000

The FCU5000 offers unparalleled, comprehensive monitoring and automatic maintenance solutions for coolant applications, ensuring the coolant system is properly managed and freeing up valuable personnel bandwidth for other tasks.

Fluid Controller – FC5000

The FC5000 can function as a stand-alone unit or in conjunction with the FCU5000 to maximize your coolant management coverage.

Solutions from Schroeder Industries can help keep you cool! Ask the experts if the FCU5000 or FC5000 are right for your application.

Contact-Blog-FCU-FC Introduction

The Cold, Hard Truth About Winter for Hydraulics & Diesel

Comments Off on The Cold, Hard Truth About Winter for Hydraulics & Diesel

Winter technically doesn’t begin until late December in the Northern Hemisphere, but cold temperatures are already setting in. Work carries on regardless of the chilly weather, but for those operating in the extreme cold, there are some important considerations when it comes to your equipment.

Winter Is Coming, Is Your Equipment Ready?

When dealing with fluid powered equipment—like hydraulic-powered machines and diesel-powered engines—cold temperatures can be detrimental to your equipment longevity and performance. Let’s explore how cold impacts hydraulic fluid and diesel fuel, and what you can do to keep your business running hot:

1. Bypass Blues: Hydraulic Cold Start Conditions

The most consequential effect of cold temperatures on hydraulic fluid is the increase in fluid viscosity.

As the fluid thickens in low temperatures, its ability to freely flow is reduced, resulting in higher differential pressure upstream of the filter. This means that until the machine warms up and the fluid viscosity is lowered, the machine may enter bypass—where the fluid passes around the filter element. The conditions that cause machines to go into bypass due to higher fluid viscosity are commonly known as cold start conditions.

So, What’s The Issue?

If the fluid is bypassing your filter and filter element, that means that unfiltered fluid is entering your system, putting critical components at risk!

Most filters on the market position the bypass at the bottom of the filter, where contamination settles as the machine sits idle. This means that when the machine goes into bypass, all that contamination is pushed straight into the hydraulic lines. Until the machine reaches sufficient temperatures and exits bypass, allowing your filtration to kick in, the contaminants will flow through the system and cause wear and tear.

What Can I Do About It?

Choosing the right filter can help protect your equipment when it inevitably enters bypass due to cold conditions. With the risks of contamination through the bypass in mind, Schroeder has designed filters that protect your equipment in cold start conditions, including:

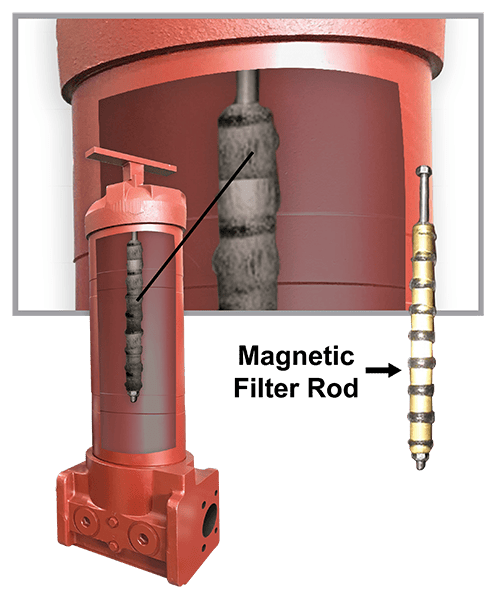

QF5i with Ferrous Contamination Protection

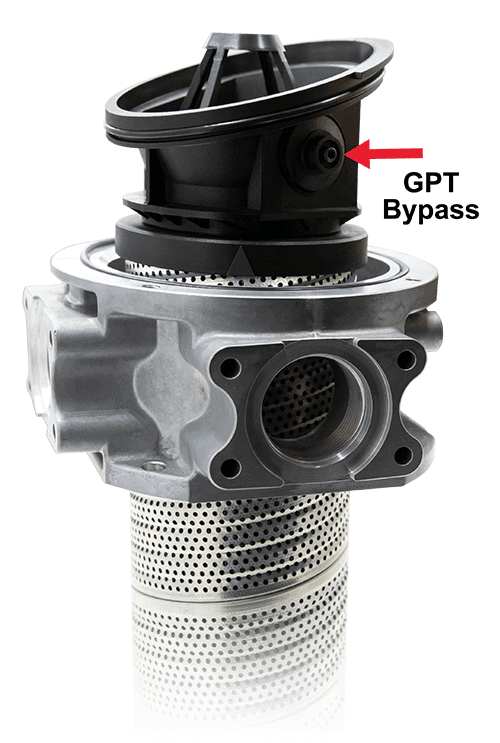

GPT Engineered for Bypass Protection

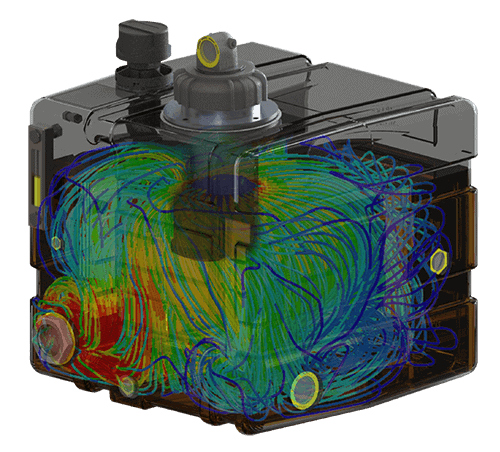

Also Consider: Hydraulic Tank Optimization

Tank Optimization has many benefits, such as reducing fluid costs and increasing available machine space. It can also improve the efficiency of equipment in cold conditions.

2. De-aeration Diminished: Increased Air Contamination

When the viscosity of hydraulic fluid increases, it also reduces the fluid’s ability to de-aerate. Thicker fluid means that air bubbles are less able to coalesce, rise, and exit the hydraulic fluid, leaving an increased amount of gas suspended in the fluid. When the system restarts, that suspended air will flow through the hydraulic system and even expand as the fluid temperature rises.

So, What’s The Issue?

Air contamination has several negative effects on equipment performance and longevity:

What Can I Do About It?

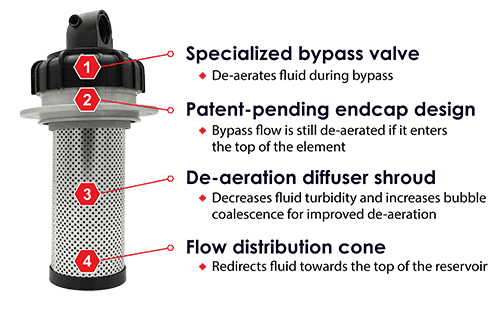

Deaeration occurs in the hydraulic reservoir, so ensuring you have the most effective de-aerating in-tank filtration on the market can help prevent air-related issues in cold conditions!

Air Fusion Technology (AFT) Filtration

Deaeration-Optimized, Cold-Resistant Rotomolded TNK

3. Frigid Fuel: Paraffin Pile-Up

Paraffin is a type of petroleum-based wax, commonly used in cosmetics, candles, and industrial applications.

As it happens, there’s also paraffin in your diesel.

Diesel fuel contains molecules of dissolved paraffin, and depending on the blend of fuel, there may be more or less paraffin in the mix.

So, What’s The Issue?

In warm temperatures, the paraffin stays dissolved, with little impact on the fuel system.

However, when temperatures drop, the paraffin begins crystallizing into a solid, which is known as diesel ‘gelling’. As these paraffin crystals begin forming, they can accumulate on dispensing filters and primary onboard filters, causing several potentially serious issues:

What Can I Do About It?

There are several ways to cut down on the harmful effects of diesel gelling when temperatures start to plummet, including the following:

Use the Right Seasonal Blend of Fuel: Summer Diesel vs. Winter Diesel

Monitor Fuel Condition with Regular Bottle Sampling & Testing