Process Filtration Inline Filters

For a complete listing of Schroeder Industries’ Inline Filter Products, click here.

Inline Filters are part of a complete process filtration system.

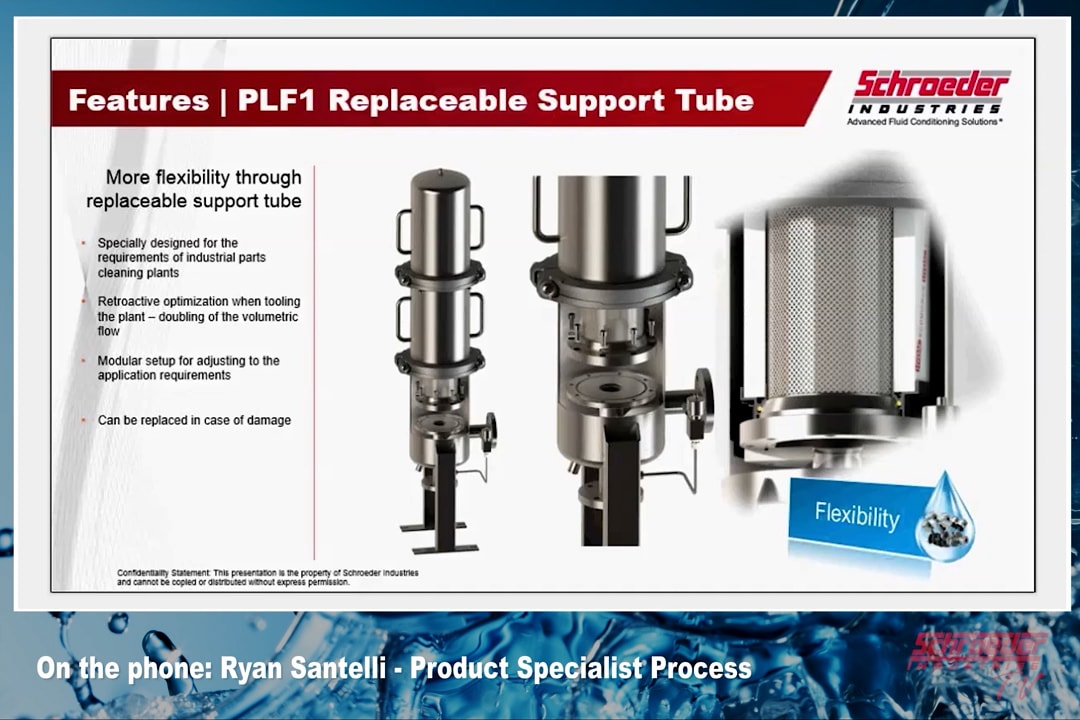

Inline filters provide effective filtration of all types of solid contamination from water based fluids. Numerous designs and filter materials ensure the best fit to the filtration task and the given process conditions:

- Temperatures up to 400 °C

- Pressures of up to 1000 bar

- Filtration ratings from 1µm (absolute) to 100µm

- Flow rates up to 3600 m3/h

- Skid and system solutions as well as special customized solutions

Schroeder’s inline process filters are manufactured in U.S. to the highest standards to effectively remove contamination from process water. Poor quality filtration results in higher maintenance costs, shorter equipment life and increased downtime. A quality filtration strategy not only removes contamination, but also increases your bottom line! For full product details, download the Inline Filter catalog section.

Know When to Change Filters

Clogging indicators monitor the differential pressure, making it easy to determine the condition of the filter at any time. The filter materials can be cleaned and reused, reducing operating costs.

Filter housings are available in carbon steel with an internal epoxy coating and in stainless steel.

Many of our inline filters are also available as gas filter variant with particle or coalescence filter elements

Inline Filter Case Study

- The high pressure deburring nozzles on a machine tool have a service life of roughly two days due to high levels of limescale.

- 15 units per month required changing at $39 per nozzle for a total cost of $585/month

- After the addition of an inline process filter, nozzle replacement cost was reduced to $19/month, a 97% reduction in costs!

The Schroeder Guarantee

Schroeder ensures protection of product and equipment, no matter what the project.

To do this, it is important to perform selective filtering of solids from gas and liquid process streams.

Poor filtering can cause a degradation of your final product or failure of equipment.

This can cause hundreds of thousands or millions of dollars in downtime or wasted product.

An infinite amount of applications and gases/liquids exist and Schroeder has the expertise to determine your optimal filtration needs. Schroeder has the optimized filtration solution based on your media, economics, permits, filtration goals, etc. This can include industrial processes, mining food and beverage, drinking water and wastewater.