Hydraulic, Diesel, Process Fluid, and Compressed Gas Filtration Solutions for the Pulp and Paper Industry

The pulp and paper industry produces a wide range of paper and paperboard products used in print, packaging, and a broad range of other applications.

Pulp and paper applications utilize a wide range of hydraulic & process fluid systems, and Schroeder Industries engineers filtration solutions that keep these vital machines moving!

Find Schroeder Industries Filtration Solutions For:

Featured solutions for your fluid conditioning and filtration needs!

Pulp & Paper Industry Case Studies

TDS-E Saves Pulp & Paper Manufacturer $10K Per Month In Oil-Related Expenses

A manufacturer in the pulp & paper market required additional water removal capacity, as their current dehydrator units were not able to keep up with the quantity of water ingression into their power generation turbine reservoir.

Through Schroeder Industries’ rental program, a TDS-E unit was provided. The unit proved so successful that the customer ultimately purchased the unit outright.

Here’s how the TDS-E benefited this customer:

Rental Program Provides Affordable, Immediate Treatment

Exceptional Oil Recovery With Minimal Maintenance

$10,000 Saved Per Month On Oil-Related Expenses

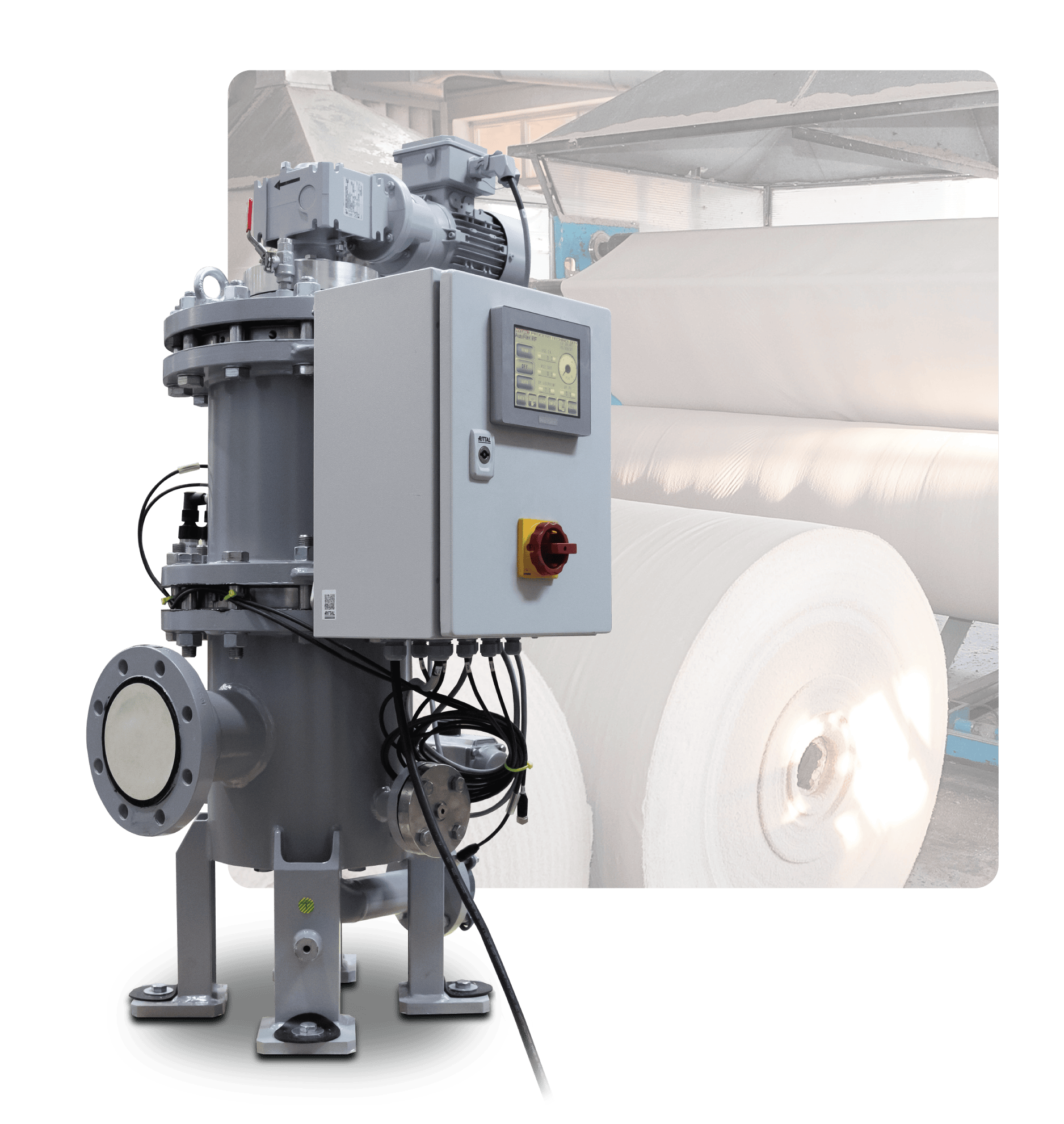

RF14 Eliminates Requirement for Manually Changing/Cleaning Basket Strainers

A major pulp and paper manufacturer was experiencing routine clogging of basket strainers on one of their paper machines due to paper fibers. This repeat clogging forced workers to clean the basket strainers at least once per shift.

Schroeder Industries implemented an AutoFilt® RF14 solution to increase filtration capability. The backflushing function of the RF14 also allows the basket to self-clean without interrupting operations or filtration.

Here’s how the AutoFilt® RF14 benefited this customer:

Increased Process Water Quality

Longer Maintenance Intervals, Reduced Downtime

Improved Personnel Safety

Anti-Stat Filter Elements Increase Oil Life, Save Thousands In Oil & Filtration Expenses

When a paper mill was experiencing a shortened filter life of just 30 days, Schroeder Industries stepped in to investigate.

Analysis revealed that high levels of electrostatic discharge in the hydraulic system were burning the filter elements and increasing contamination levels. By applying a specialized anti-static filter element, the customer saved thousands on oil and elements.

Here’s how Anti-Stat Media (formerly Anti-Stat Pleat) benefited this customer:

Oil Service Life Increased +3 Years

Annual Oil Usage Decreased -951 Gallons

$24.8k Annual Filter & Oil Cost Savings

Coming Soon.

You could be Schroeder’s next success story! Let us know how we can help.

How can we improve your filtration & equipment performance? Ask the experts!

Request a Quote:

Ask the experts!