Hydraulic Filter Elements

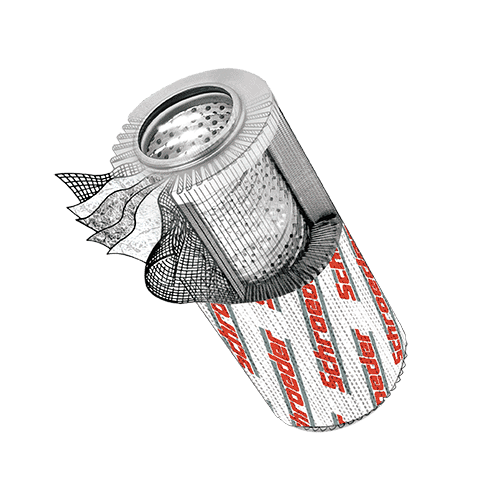

Filter elements are the heart and soul of every high pressure fluid power system.

The role of the filter element, which sits inside the filter housing, is to capture contamination particles while maintaining appropriate differential pressure for system operation. Filter elements can be optimized for the capture of specific micron sizes, or formulated for special scenarios including water contamination and the presence of static.

While filter elements are disposable, it’s important to never compromise on filter element quality!

Schroeder Industries Element Technology

Non-Schroeder Elements in Schroeder Housings

Not all elements are created equally! Due to the possibility of a fit, form, and function error, Schroeder Industries does not recommend nor guarantee that a non-Schroeder filter element can be used properly in a standard Schroeder filter housing.

Generic or competitor elements may not meet the operational specifications that allow a Schroeder filter to perform at its best. By substituting a will-fit filter element, you may be compromising system efficiency and experience equipment downtime.

Element Technology Solutions from Schroeder Industries

Schroeder Industries is backed by over 75 years of manufacturing experience. Our filter elements are engineered to excel, with comprehensive options for virtually any application:

Featured Element Technology Solutions

Combined with our range of premium filter elements and other hydraulic accessories, our filters are engineered for excellence in removing contamination. Here are just a handful of Schroeder’s industry-leading hydraulic filters:

Excellement® Media

The foundational technology of Schroeder Industries’ exceptional filter elements!

Aqua Excellement®

The dirt-catching power of Excellement® with potent water removal capabilities!

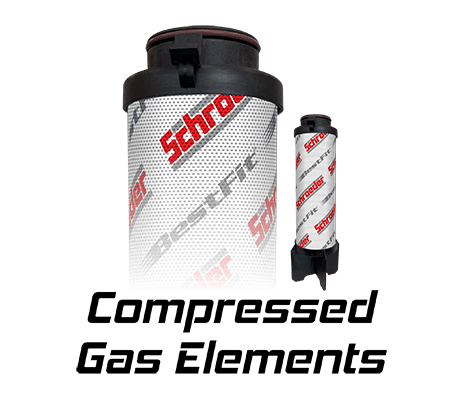

CGF Elements

Elements engineered for the unique needs of compressed gas filtration applications!

E-Drive Media

With exceptionally low pressure drop, ideal for battery drive hydraulic circuits and more!

Anti-Static Elements

Elements which dissipate static in virtually any electrostatic discharge (ESD) scenario!

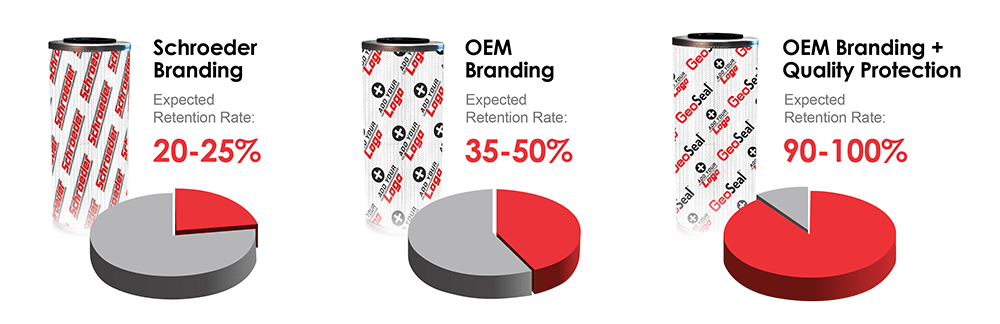

Quality Protection

When end users turn to generic, will-fit elements to cut costs, the impacts on their equipment can be catastrophic. Too often, the blame falls on the OEM rather than the substandard element which compromised the hydraulic system.

Quality Protection is Schroeder’s answer to the use of cheap substitute elements, and allows for increased system protection!

GeoSeal

A Quality Protected Solution

The unique, geometric sealing of this element prevents substitution of low-quality element substitutes.

Lock & Key™

A Quality Protected Solution

Features a ‘lock and key’ interface between the bushing and element which can be uniquely customized.

Private Labeling and Element Aftermarket Retention

Ask Us About Private Labeling!

Private labeling your filter elements is a great way to increase aftermarket revenue, reduce warranty claims, and ensure that your customers are using high-quality elements that keep their machines running better, for longer!

Schroeder Industries can work with you to create customized element wraps featuring your company logo and branding.

Ask about how you can benefit from private labeling!

Case Studies: Element Technology

Don’t just take Schroeder’s word on the quality of our products. Here are just a few success stories highlighting how solutions from our Element Technology group saved our customers money, downtime, hassle and more!