Fluid Contamination Control: What You Need To Know

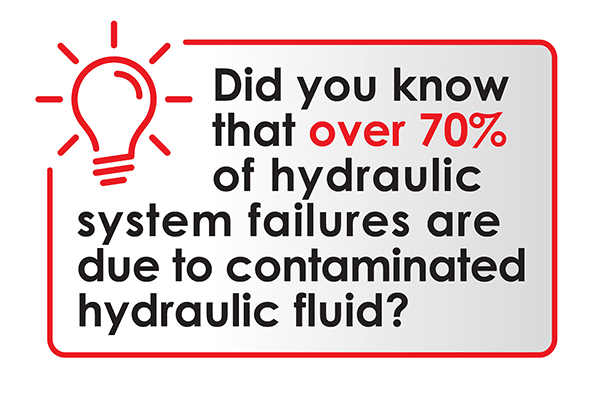

Did you know that over 70% of all hydraulic system failures are caused by contaminants in the fluid?

Ingression of solid particulates, liquid, and air bubbles are constant threats for hydraulic equipment. Without proper filtration, these contaminants can impact your vital equipment in many ways:

Hydraulic filtration is the key to controlling contamination and protecting your equipment.

Schroeder Industries is a global provider of high-performance, high-efficiency filtration solutions, including our range of onboard hydraulic filters. Our experts can work with you and your team to determine a treatment plan for your hydraulic fluid and guide you towards the optimal products and solutions for your filtration needs.

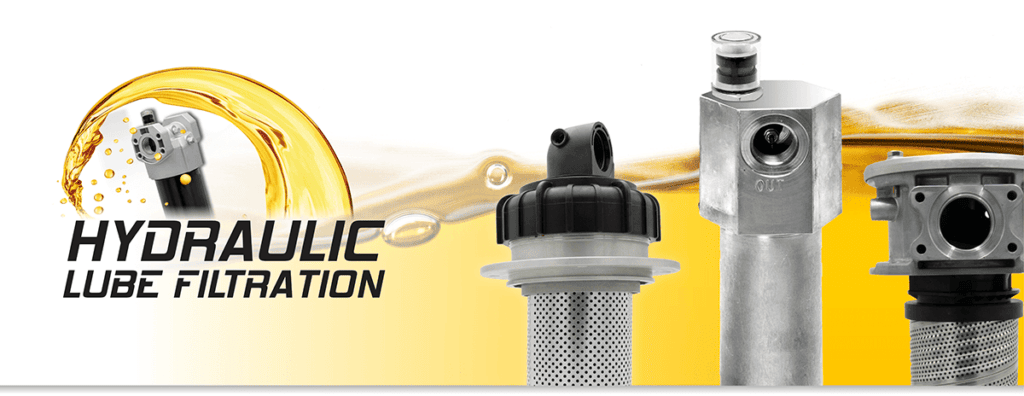

Hydraulic & Lube Filtration Solutions from Schroeder Industries

Schroeder Industries is backed by over 75 years of manufacturing experience. Our hydraulic filters are made in America and engineered to excel, with comprehensive options for virtually any application:

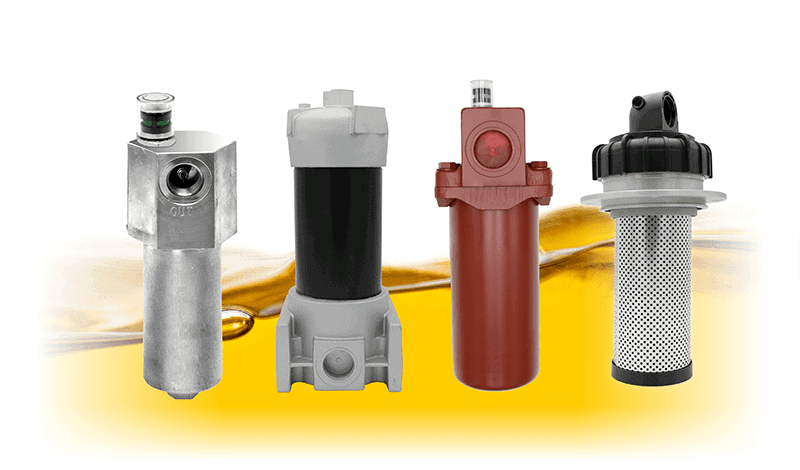

Featured Hydraulic & Lube Filters

Combined with our range of premium filter elements and other hydraulic accessories, our filters are engineered for excellence in removing contamination. Here are just a handful of Schroeder’s industry-leading hydraulic filters:

Air Fusion Technology (AFT): Engineered for Optimal De-Aeration

GPT: Advanced Cold Start Protection with a Sustainable Twist

NF30: Rock-Solid Filtration in High Pressure Applications

QF5: A Medium Pressure Workhorse with Straightforward Maintenance

Case Studies: Hydraulic & Lube Filtration

Don’t just take Schroeder’s word on the quality of our products. Here are just a few success stories highlighting how hydraulic filters from Schroeder Industries’ Hydraulic and Lube group saved our customers money, downtime, hassle and more!