Water Glycol Filtration – What to Know When Switching from Mineral Based Hydraulic Fluids

For a complete listing of Schroeder Industries Top-Ported:

-

High Pressure Filters, 3000 – 6000 psi (210 – 415 bar), click here

What is Water Glycol?

Water Glycol is an ethylene glycol that contains between 35-75% water and is typically identified with a pink or red dye.

Water Glycol also brings additional worker safety to the workplace with greater fire resistance than mineral oil. In applications where there is a lot of heat being produced, water glycol, is a much safer fluid to use.

Water glycol is being used in applications where environmental regulations must be observed.

Description of Water Glycol:

Water glycols can increase machine efficiency by lowering fuel and electricity consumption, increasing work completed per shift, and easier cold starts. With a more efficient machine there is also less operation costs, smaller emissions footprint, and an increased rate in production. This is of particular importance with the electrification of machines and green initiatives increasingly being applied. For example, a case study was completed on a plastic injection molding machine that showed that water glycol made this hydraulic system up to 8.5% more efficient than traditional oil-based fluids. This efficiency gain correlates to an annual reduction of about $100,000 in electricity costs and an annual reduction of 174 tons in carbon dioxide emissions for the company.

Water glycol is also an excellent fluid choice when it comes to fire-resistance in hydraulic fluid. Many industries including foundries, die casters or any application where hydraulics is near a heat source requires a hydraulic fluid with greater fire safety than mineral oil in order to create a safer work environment. Water glycol is also being more used in applications where environmental regulations must be observed.

Why are people switching?

Water Glycols can increase machine efficiency by lowering fuel and electricity consumption, increasing work completed per shift, and easier cold starts.

With a more efficient machine there is also less operation costs, smaller emissions footprint, and an increased rate in production.

Water Glycol also brings additional worker safety to the workplace with greater fire resistance than mineral oil.

In applications where there is a lot of heat being produced, Water Glycol, is a much safer fluid to use. Water Glycol is also being more used in applications where environmental regulations must be observed.

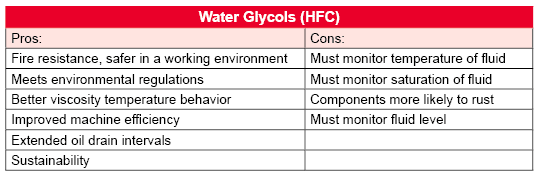

Pros and Cons

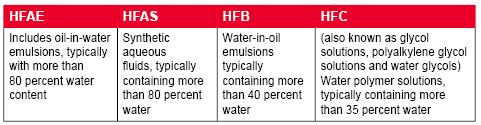

There are Four Categories of Water-Based Fluids Defined by ISO

HFC is the most common water-based fluid because of its excellent fire resistance and hydraulic properties.

Water Glycol Considerations:

Since Water Glycol consists of mostly water, the lubrication properties are much different compared to oil-based fluids.

Oil based fluids relation between viscosity and temperature is based on viscosity index. Water Glycol has a much better viscosity temperature behavior than mineral oils.

Temperature must be monitored when using Water Glycols, temps exceeding 120F (50C) accelerates the aging process of the fluid. Too much water loss increases viscosity and reduces fire resistance. Water loss can also affect viscosity, pH, and lubrication quality.

All added water to the system must be distilled or deionized water. This is because the calcium and magnesium present will react with additives, causing them to precipitate out and effect fluid performance.

Materials of filter construction:

Seals:

Standard Buna and Viton seals will work well with Water Glycols. A 2015 study was done to investigate the effects of water glycol on common seal material and through testing it was found that HNBR was the best all-around seal at any temperature for water glycols with FFKM and PTFE performing best at higher temperatures.

Metals:

Metals such as Aluminum, stainless steel, and carbon steel have good compatibility with Water Glycol. It is recommended treatment is done to the metals to increase longevity of the material and to prevent rust. If no treatment is done, the iron oxide could mix with Water Glycol causing performance issues with the hydraulic components.

Products:

- All aluminum in the filter should be anodized. This can be accomplished by using the “W” option as shown in the filter model number selection chart.

- Potential exists for cavitation problems with water glycols like high water-based fluids. SKB suction separators are recommended for pump protection from ferrous or large particles.

- Frequent element changeouts are okay with standard carbon steel elements. If your element changeout intervals are not as frequent, please consider using treatments done to metal components and/or switch to plastic.

Find hydraulic filters near me