Quality Service Integrity at Schroeder Industries

Price is the typical deciding factor when it comes to buying behavior.

When it comes to filtration, if a low price point is the only value factor, this can lead to a disappointing discovery due to the cheaper options usually performing at a less-than-satisfactory level when compared to the original product it is ripping off.

To make the matter worse, the end-user often points an accusing finger at the filter housing manufacturer for poor element performance, rather than the inadequate element manufacturer they used as a will-fit replacement.

That is where Schroeder’s Quality Protection is the answer.

Quality Protection is the Schroeder Suite of patented element offerings. When a customer signs up for Quality Protection from Schroeder Industries, this guarantees a consistent level of service on their equipment (and ours).

What is Schroeder’s Quality Protection?

To put it simply, our line of Quality Protected Products qualifies as patented or proprietary filter elements, element-types, bushing arrangements, housing configurations, and other options that best ensure the use of proper fluid conditioning regimens and equipment!

If an OEM and end-user customer is looking for guaranteed hydraulic system integrity, Quality Protection is the answer.

Request a Review for Quality – Schroeder’s Quality Protection

Request for Quote

Benefits of Quality Protection (OEM)

When an original equipment manufacturer (OEM) builds a piece of heavy equipment, it is often times their goal to keep the machine running at the level in which it was designed, even after it leaves the plant.

These machines undergo stringent testing and operate at a comparable condition to how the engineers imagine their end-users will use them.

The system engineers then choose the components they feel will match the level of quality they designed to and want to ensure a swift operation in the field, and with minimum warranty claims.

Here are just several of the ways our OEM customers have benefitted from Schroeder’s Quality Protection Program:

- No longer purchasing low quality elements

- Reduced warranty claims

- Captive aftermarket

Schroeder’s Quality Protection then becomes a bigger topic in the conversation as equipment built with our patented solutions

ensure that it’s our level of filtration that is replaced every time.

It also ensures that the OEM remains the point of contact for spare parts replacements.

Along with a fiscal perk, quality protection brings peace of mind for all parties involved.

Benefits of Quality Protection (End-User)

When the end-user purchases heavy equipment, it’s often their goal to be as productive and profitable with the machine at hand.

What may look like a cost-savings upfront by purchasing a cheap will-fit element quickly becomes a scramble when they lose manhours ($) constantly replacing the filter element ($$) and not too mention the amount of contaminant entering the system through the faulty product ($$$).

Here are just several of the ways the end-users of our OEM customers have benefitted from Schroeder’s Quality Protection Program:

- Decreased cost of ownership

- Improved productivity in equipment

When the end-user purchases equipment with industry-recognized Schroeder Quality Protected Filtration, they can rest assured knowing that the level of performance will remain consistent, leaving them feeling productive and able to clock-in and clock-out on schedule.

Schroeder’s Quality Protected Offerings:

Introduction to DirtCatcher®

As a first line of defense in the suite of Quality Protection, we have our DirtCatcher® filter element design.

DirtCatcher® offers superior alternative inside-out filtration.

The patented outer shell prevents contaminants from falling back into the system during element changes while still providing the excellent dirt retention of Excellement® media.

The DirtCatcher® solution provides peace of mind to those concerned with dirt escaping from elements during the removal process while delivering all the advantages of Schroeder original (outside-in flow) elements.

Introduction to GeoSeal®

GeoSeal® is a patented offering that provides a unique way for OEMs to retain replacement element business and keep a filter’s performance at the quality level that it was originally supplied.

The idea is brilliantly simple: the critical sealing arrangement between a filter housing and its replacement element takes on a shape other than the standard circular arrangement.

Specifically, the element grommet & mating bushing are given a new geometric shape.

Schroeder offers three pressure types of QP filters

- High Pressure

- GKF30

- GKF50

- GKC50

- GKC65

- GMKC60

- Medium Pressure

- GK9

- GKF5

- Low Pressure

- GRTB

- GZT

- GRT

- GLRT

- GKTK

- GLTK

- ART

- GKF3

- ART

- GKL3

- GMLF1

Contamination causes vast issues within equipment. Quality Protection can keep those issues at bay.

Introduction to HydraSPIN Filters

Only filters to offer a full range of a cartridge style element, but in a robust metal housing.

- Up to 35 gpm (130 L/min) HydraSPIN Filters (GH6 & GH9)

- Up to 87 gpm (325 L/min) HydraSPIN Filters (GH11 & GH14)

Capable of delivering the best performance solution for any application hydrostatic or CVT application challenge.

Private Label Branding – Outer Wraps & End-Cap Etching

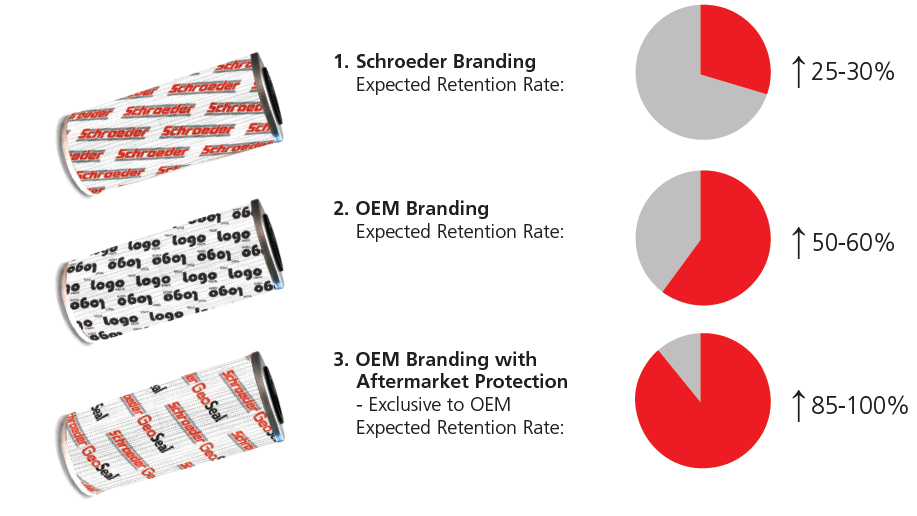

Schroeder offers a full line of branding solutions for air breathers, spin-ons, and replacement elements.

This program allows for custom-branding a high performing Schroeder product.

- Our filter housings, elements, spin-ons, and air breathers come with the option of Private Label Branding:

- Your brand identity logo on a high-performing filtration solution from Schroeder

Assures that OEM’s and end-users get the highest performance original fit elements, but recognize the product as branded per our partner’s logo identity.

Damage Caused by Contamination

- Surface scoring and wear results in:

- Loss of oil through internal leakage

- Loss of efficiency

- Loss of position holding characteristics

- Fine particle build-up results in:

- Erratic hydraulic system performance

- Fluid degradation results in:

- Particle contamination which speeds up rust and corrosion