Hydraulic, Diesel, Process Fluid, and Compressed Gas Filtration Solutions for the Steel Industry

Steel forms the backbone of much of our vital infrastructure, vehicles, appliances, and other products. Refining this versatile metal into usable material is an intensive process which requires efficient equipment performance in industrial settings where contamination is abundant.

Steel production facilities utilize a wide range of hydraulic and diesel-powered machinery, and Schroeder Industries engineers filtration solutions that keep these vital machines moving!

Find Schroeder Industries Filtration Solutions For:

Featured solutions for your fluid conditioning and filtration needs!

Steel Industry Case Studies

RF14 Clears Cottonwood Contamination from Cooling Water

When a steel mill was experiencing frequent clogging in their equipment, forcing frequent and costly downtime to unclog nozzles and other components, Schroeder Industries identified cottonwood seeds and fluff as the culprit!

The customer’s cooling water supply was exposed to seasonal cottonwood contamination through its cooling towers, which drew in enough fibers to cause serious clogging.

Fortunately, the AutoFilt® RF14 is designed for exactly this type of scenario, and was able to eliminate these service interruptions!

Here’s how the RF14 benefited this customer:

RF14 Backlflushing Allows Continuous Filtration

Cooling Water Quality Maintained

No Service Interruptions Since RF14 Installation

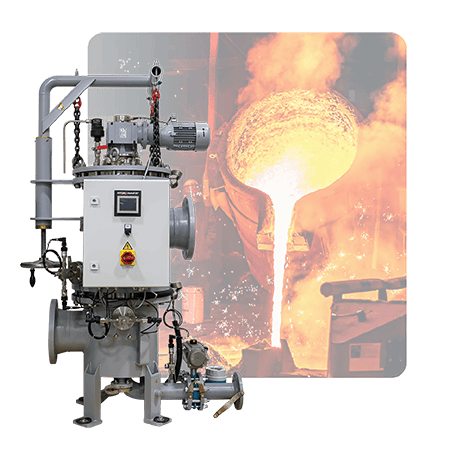

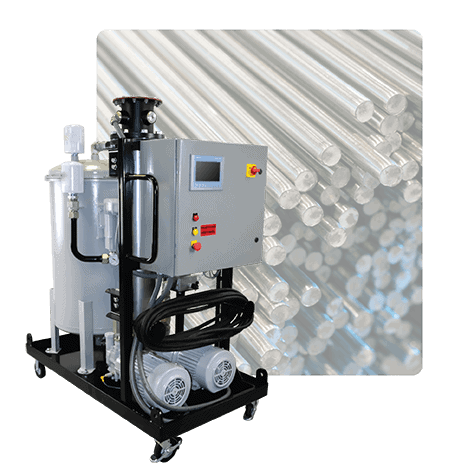

TDS-E Provides 70% Hydraulic Fluid Saturation Reduction for Stainless Steel Producer

A domestic stainless steel producer based in Alabama was experiencing failures in their water cooled heat exchanger due to high concentration of water present in their hydraulic fluid (approximately 900 gallons).

When a competitor rental dehydrator was unable to make progress on reducing the hydraulic fluid saturation levels, a TDS-E from Schroeder Industries provided rapid results!

Here’s how the TDS-E benefited this customer:

50% Saturation Reduction in 15 Hours

30% Saturation Reached and Maintained

Downtime from Water Contamination Reduced

Coming Soon.

You could be Schroeder’s next success story! Let us know how we can help.

How can we improve your filtration & equipment performance? Ask the experts!

Request a Quote:

Ask the experts!