Self-Flushing Filter Results in Better Economic Impact

The following story is part of Schroeder’s success stories or “Technical Application (TAB) Bulletins”. A cut sheet of this can be shared with by contacting your local Schroeder Industries representative and asking for L-4946_Process Filters TAB.

Each Schroeder Industries “TAB” is broken out in steps. This better illustrates the approach of the successful process.

Confidentiality Statement: This information is the property of Schroeder Industries and cannot be copied or distributed without express permission.

DISCOVER

- Customer experienced clogged furnace spray nozzles due to a neglected cooling tower.

- Small plastic fines from the cooling tower stopped cooling water to furnace wall resulting in a melted wall. Luckily no one was injured.

DIAGNOSE

- Filtration of 100 micron was targeted for a 36 inch flooded water pipe.

- A basket strainer would have to be very large to meet the flow and pressure drop requirements.

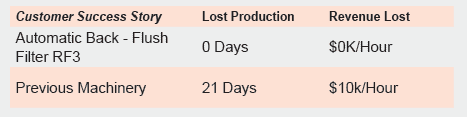

- The basket strainer would require periodic maintenance to clean, stopping the water flow and system processes – at $10,000 per hour of lost production.

DESIGN

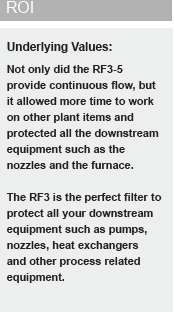

What We Did: Schroeder Industries employed the RF-3-5 self-flushing filter with uninterrupted flow and only 3-7 PSI drop while flushing.

Course of action

- Schroeder Industries chose to use the Automatic Flush Filter RF Series because it removes particulate and flushes automatically.

- The variable housing configurations provide the inlet and outlet flanges and the back-flush line to be arranged in various positions, making it possible to integrate the filter easily into any system geometry.

DELIVER

- 6 Automatic Backflush Filter RF-3s have been purchased over the last 5 years.

- Implementing the RF3 helped with cost-savings of labor and down-time. Less chemically treated water required for backwashing resulting in lower environmental impact and chemical cost savings.

- The uninterrupted water supply was the most important aspect in the purchases of the RF3.

CUSTOMER BENEFITS

- Uninterrupted cooling spray for continuous production.

- Self-flushing requires no labor costs.

- Safe and maintenance free.

FURTHER APPLICATION AREAS

- Caster

- Roll Mill

- Beam Mill for nozzle protection

- Pump & Heat Exchanger Protection

PRODUCT SPECS

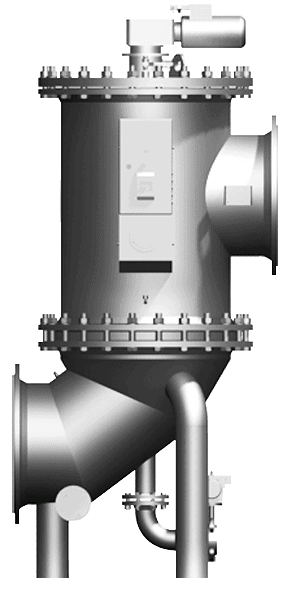

RF3: Automatic Backflush Filter Technologies

Flow Range: 6600 – 10,790 gpm (25,000-40,850 L/min)

Working Pressure: 87 psi (6 bar)

Max Working Temperature: 194○

Empty Weight: 2250 lbs. (10200 kg)

Housing Volume: 168 gallons (635L)

Filter Area: 8640 in.2 (55,760 cm2)

No. of Filter Element: 24