Hydraulic, Diesel, Process Fluid, and Compressed Gas Filtration Solutions for the Marine Industry

Marine vessels encompass massive freighters, cruise ships, drilling support vessels, recreational craft, and everything in between. Whether these ships are carrying passengers, transporting supplies, or supporting vital marine operations, system protection through filtration is paramount for safety and efficiency.

Marine applications utilize a wide range of hydraulic and diesel-powered systems, and Schroeder Industries engineers filtration solutions that keep these vital machines moving!

Find Schroeder Industries Filtration Solutions For:

Featured solutions for your fluid conditioning and filtration needs!

Marine Industry Case Studies

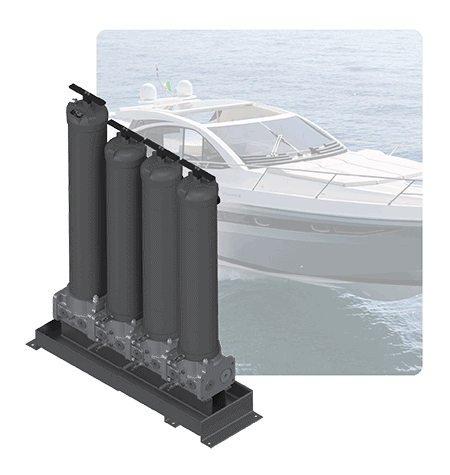

BDS3 Protects Luxury Vessels from Contamination-Related Damage, Downtime

A corporate marina providing diesel fuel to luxury vessels struggled with water contamination in their bulk tanks and dispensing pumps, posing a threat to the vessels utilizing the marina’s harbor services.

Schroeder Industries provided a Bulk Diesel Skid 3 (BDS3) with an integrated system pump and four stages of coalescing and particulate filtration. Ensuring clean, desaturated diesel fuel enabled the marina to better serve their customers.

Here’s how the BDS3 benefited this customer:

Protection From Fuel-Related Legal Liabilities

Improved Customer Safety & Satisfaction

Protection From Repairs Costing $10K – $100k+

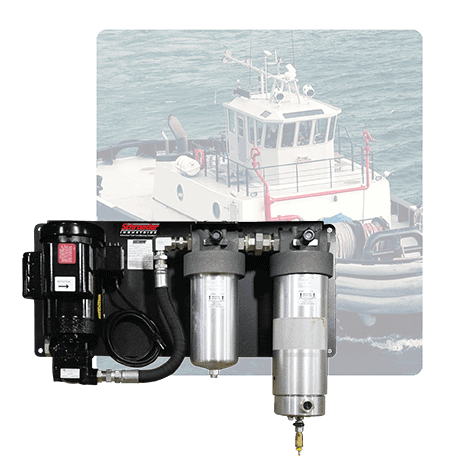

Work Boat Fleet Regains Trust In Their Fuel Quality Thanks To BDFP Polishing System

When a fleet operator in the Mississippi River region launched a new pushboat with a brand new engine, the pushboat experienced sudden engine failure just a single mile into its maiden voyage.

When analysis revealed that water contamination in the fuel was the primary cause of the failure, Schroeder Industries recommended a kidney loop setup featuring the BDFP to ensure fuel quality and protect from further unexpected failures.

Here’s how the BDFP benefited this customer:

Reduced Downtime & Maintenance

Eliminated Contamination-Related Engine Failures

Prevented Major Engine Repairs (Saving Up To 100K+)

Coming Soon.

You could be Schroeder’s next success story! Let us know how we can help.

How can we improve your filtration & equipment performance? Ask the experts!

Request a Quote:

Ask the experts!