Work Boat Fleet Regains Trust in Fuel Quality

The following story is part of Schroeder’s success stories or “Technical Application (TAB) Bulletins”. A cut sheet of this can be shared with by contacting your local Schroeder Industries representative and asking for L-4888_Fuel Filtration TAB.

Each Schroeder Industries “TAB” is broken out in steps. This better illustrates the approach of the successful process.

Confidentiality Statement: This information is the property of Schroeder Industries and cannot be copied or distributed without express permission.

DISCOVER

- This application came to us through a distributor with whom we have a close partnership.

- The customer operates three full-service fleets providing services on the Mississippi River.

- Their fleets currently include 29 tow boats as well as 11 launch boats.

DIAGNOSE

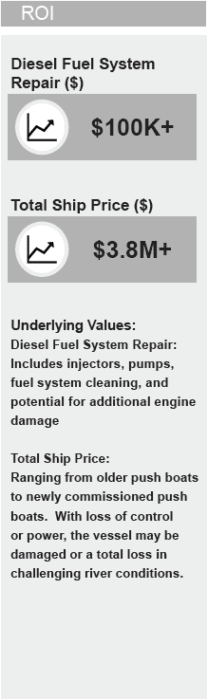

- In early March of 2019, the customer launched a new push boat (with brand new fuel system and engine) that only made it out of the dock approx. 1 mile before having a catastrophic diesel engine failure due to symptoms of water and excess water in fuel.

- The customer immediately approached our distributor, who has had a long standing business relationship with the customer, looking for possible solutions.

DESIGN

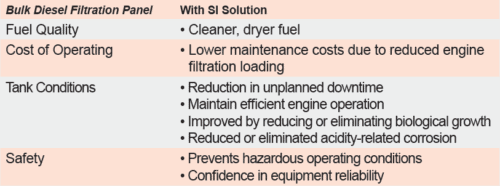

What We Did: We presented our BDFP (Bulk Diesel Filtration Panel) fuel filter demo stand to the customer and they were impressed at the water removing capabilities shown via the demo.

The marine industry is heavily regulated, making our goal to support their needs while minimizing regulatory costs. Understanding the customer’s application, we recommended a kidney loop setup to be able to avoid the costly and difficult marine approval standards.

Course of action

- We presented our distributor’s demo stand to the customer, demonstrating our water removal capability.

- Working with the customer, we developed a BDFP configuration that included our automatic water drain (AWD).

- The customer immediately purchased seven (7) BDFP’s with AWD5 for the purpose of running a kidney loop system in the engine rooms of seven (7) of their vessels.

DELIVER

- As of March 2020, the customer has purchased (10) BDFP’s with auto drain and have plans to purchase 10-15 additional units to complete the installation across their fleet within the year.

- Since installation of the BDFP units, the customer has had no additional engine failures due to water in their diesel fuel.

- This customer has been a positive reference in the industry to allow for continued promotion with other work boat fleets.

CUSTOMER BENEFITS

- Turn-key polishing and transfer filtration system incorporating Automatic Water Drain.

- Minimal clearance needed for element service, ideal for limited installation space.

- High performance particulate element to ensure clean and dry fuel with low operating costs.

FURTHER APPLICATION AREAS

- Bulk fuel transfer systems

- Agricultural, mining, construction, or fleet fuel dispensing

- Fuel polishing system for regular fuel conditioning or long term storage

PRODUCT SPECS

Bulk Diesel Fuel Panel | with AWD

Flow Rate: 14 or 25 gpm

Electrical Service: 115/208-230 VAC 60Hz Single Phase

Particulate Filtration: 1 or 3 micron

Coalescing Filtration: >95% Efficient

Sealing Material: Fluorocarbon (FKM, Viton)

Housing Materials: Anodized Aluminum