Revitalize Your Mobile Filtration with Powerful Cart Systems

Leave a Comment

Click here to view a complete listing of Schroeder Industries’ Filter Cart Systems

In addition to an in-line hydraulic filtration strategy, an offline filter system can greatly enhance the cleanliness of hydraulic fluid. A Filter Cart System is a stand-alone unit that operates independent of the main hydraulic system, allowing it to function even when the machine is turned off.

Often referred to as an offline filtration or kidney loop systems, Filter Cart Systems have many application points within a plant or factory:

- Filtering incoming hydraulic fluids prior to adding to bulk storage

- Filtering new fluid before it is put into service

- Fluid transfer and filtering before adding to a hydraulic reservoir

- Supplementing current hydraulic filtration already in the system

- Roll-off cleanliness – cleaning a reservoir on a piece of equipment prior to shipment to ensure peak fluid condition

- Cleaning up a hydraulic system following component replacement

Whether your machine is new or many years old, the cleaner the hydraulic fluid, the better the operating condition. In hydraulic systems, 70 to 90% of wear and failure is contamination related. Issues such as defects, misuse or age can be traced to only 10 to 30% percent of failures.

While clean fluid is critical to proper system operation, unfortunately, contamination cannot be stopped. However, with Schroeder Industries technology, it can be managed!

Schroeder Industries Filter Cart Systems

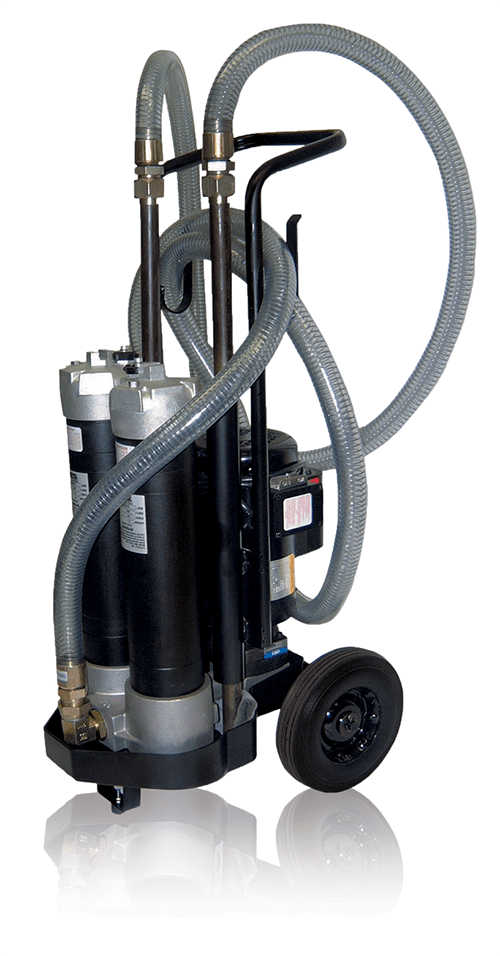

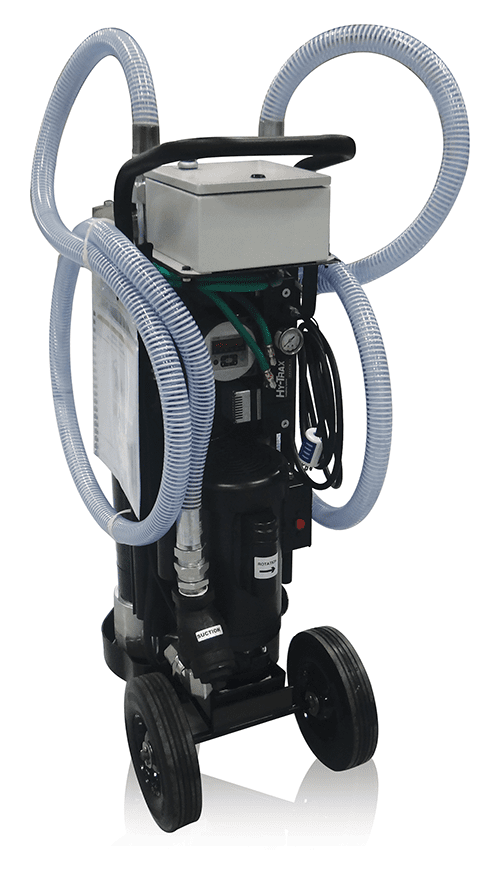

Schroeder Industries offers up to 10 different types of Filter Cart Systems. All of these carts offer the convenience of mobile use. The mobility allows for easy portability and requires less storage space.

Our filter carts are equipped with high efficiency filter elements to remove solid particulates and/or free water quickly and efficiently. The onboard filtration systems are available in either single (one filter) or staged filtration (two filter) configurations.

Our systems range from simple filtration carts (hose to reservoir, powered on, processed through a filter) to our SMART® carts (diagnostic and SMART® controlled components in addition to the standard filter cart process mentioned above). These include contamination monitoring units such as our CS1220, AS1008 and sensor interfaces for data logging and data transfer.

Various flow rates are available depending on model code selected. Kidney loop systems can also be designed for a particular application.

Watch on YouTube “How To Make Your Schroeder Filter Cart SMART®”

Case Studies

Here’s a small selection of our customers who benefited from the superior filtration capabilities of Schroeder Filter Cart Systems:

Learn more about custom engineered filtration solutions from Schroeder Industries!

Whatever it takes to tailor a Schroeder filtration system to your machinery and application, our engineers can develop solutions to suit your filtration needs.

Hydraulic Filtration Solutions from Schroeder Industries

Want to protect your valuable hydraulic equipment? Schroeder Industries offers a full range of filtration solutions, backed by decades of proven quality and innovation in the field of fluid filtration. Contact us for more information on how our filter carts and other hydraulic filtration products can enhance your equipment.

Request a Quote – Filter Cart Systems

Request for Quote

Prolong Fluid & Equipment Life With Kidney Loop Filtration Systems

Leave a Comment

What Is A Kidney Loop System?

Kidney loop systems clean hydraulic fluid and prolong the life of the fluid, filters and equipment. These external filtration systems draw hydraulic fluid directly from the reservoir into a short filtration circuit, then return the cleaned fluid to the reservoir. A kidney loop system can be used to supplement in-line filters when the in-line filter does not provide adequate turnover.

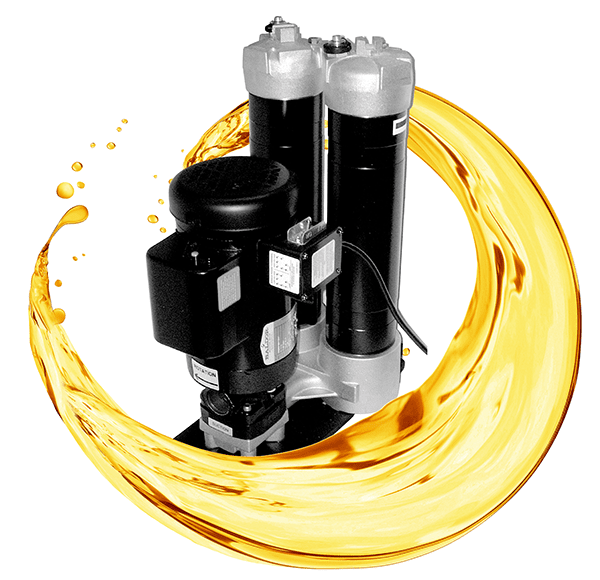

Schroeder’s Kidney Loop System is an off-line stationary version of the kidney loop filter systems on portable carts. It is a compact, self-contained filtration system equipped with high efficiency, high-capacity elements capable of removing particulate contamination and/or water contamination quickly, conveniently and economically.

Keeping Hydraulic Fluid Clean

In a system where only one filter is used, this one filter must remove all of the dirt generated in the system.

By using both pressure and return filters in the system, the work load is shared, making it easier to maintain the recommended fluid cleanliness level for the hydraulic system. However, the reservoir might still contain contamination accumulated over time and from the environment.

An off-line kidney loop system can be added to remove solid particles, improve reservoir cleanliness, and extend the life of the system’s filter elements.

In hydraulic systems, 70 to 90% of wear and failure is contamination related! Only 10 to 30% can be traced back to misuse, defects or age. Contamination cannot be stopped, only slowed down.

System efficiency can drop by up to 20% before an operator even detects a problem. This can appear as cylinder drift, jerky steering, erratic operation or slower performance. Overall, contamination results in shorter service intervals, higher operating costs and lost productivity.

A major portion of particulate contamination can be effectively and efficiently removed by using our kidney loop systems. Reduced downtime, fewer repairs, and more efficient operation can save a company production costs in the future.

Schroeder Industries offers several different types of stationary kidney loop systems, including versions with pneumatic motors in place of standard electric motors. The pneumatic motor offers the same flow capability using the same components, but without the need for an electrical outlet. The greater portability allows for field options on service trucks.

Watch to learn more about Schroeder Industries’ Kidney Loop filtration offerings and how they can benefit your hydraulic systems!

Kidney Loop Filtration Systems vs. In-Line Filtration Systems

A kidney loop system is a fully independent filtration unit, containing its own motor, pump, and filter. The kidney loop system can be linked directly to a reservoir and run intermittently as required, or continuously. Since they function independently from the machine’s hydraulic system, kidney loops are more efficient at removing contamination from fluid and retaining any captured dirt within the filter.

Typical in-line filtration systems only run when the hydraulic machinery is active. The key benefit of a kidney loop system is that it can run 24/7 and polish the hydraulic fluid even when the machinery is powered down.

Applications

- Supplementing in-line filtration by system filters when adequate turnover cannot be attained

- Large volume systems requiring multiple filters in different locations

- Cleaning up a hydraulic system following component replacement

Success Story

Problem: A customer was experiencing problems with external ingression of coal dust getting into the 255 gallon (965 L) lube oil reservoirs on their coal pulverizers. This caused degradation wear on the bearings and bull gears, which lead to premature aging of the system components.

Solution: The installation of KLD filtration skid cleaned up the system fluid from coal dust particulates and other contamination. As a result, the internal wear on system components as well as unscheduled downtime due to contamination was reduced dramatically.

Watch to learn more about Schroeder’s Kidney Loop product extensions:

Request a Quote: Kidney Loop Systems

Request for Quote